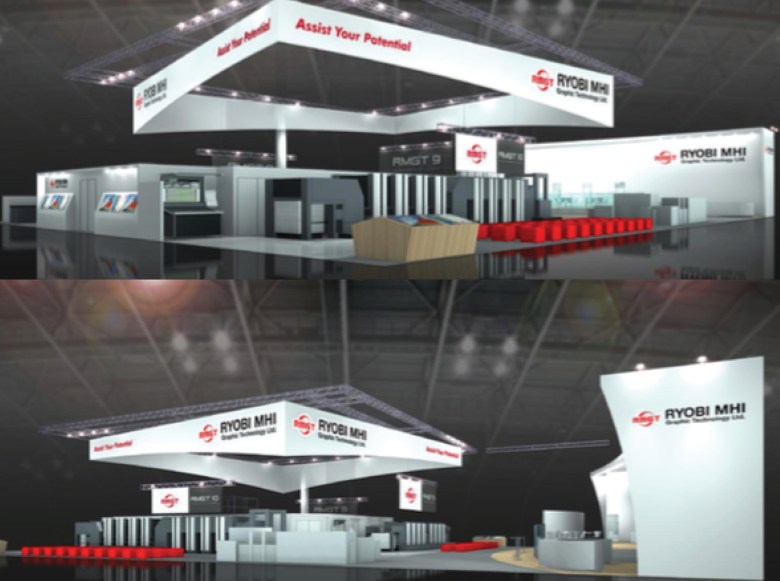

Visualisation, automation and connection will be the concepts on show when RMGT – RYOBI MHI Graphic Technology showcases its new technologies at drupa in June.

Using the theme “Assist Your Potential with Technological Expertise and Constant Innovation”, RMGT will present a vision of the printing company of the future centered around its B1-size RMGT 10 and A1-size RMGT 9 offset presses and their advanced automated functions.

This vision of the future will include Automated Guided Vehicles (AGVs), postpress processes and other operations which are all connected via the RMGT Press Information Cloud (PIC).

RMGT will bring a number of new solutions to the show including the RMGT Press Information Cloud, RMGT 10 B1-size 8-colour tandem perfector, RMGT 9 A1-size 8-colour convertible perfector, RMGT 9 A1-size 5-colour offset press (with a coating unit) and Automated Guided Vehicles (AGVs).

RMGT Press Information Cloud (PIC)

The RMGT Press Information Cloud (PIC) aims to connect the printing company’s main system with the RMGT Press Information Edge (PIE) that serves as the press interface. PIC can understand and learn the content of each printing job to optimise the printing sequence and ink conversion curve, further expanding the benefits of automation. Utilising the press operating conditions and productivity criteria, visualised by the PIC, printing companies can quickly implement a PDCA cycle to increase productivity.

The RMGT 10 B1-size 8-colour tandem perfector will see the automation and labour saving functions of the RMGT 10 series evolve even further since IGAS 2018, enabling continuous high-grade colour perfecting for commercial printing jobs.

The RMGT 9 A1-size 8-colour convertible perfector has been updated with a number of new functions for higher productivity. This pertains not only to operation of the press itself, but also on postpress processes facing serious labor shortages, automating workflow from printing to binding.

As for the RMGT 9 A1-size 5-colour offset press, the drupa exhibit will include printing demonstrations of solutions to meet the needs for high-value-added printing and packaging printing.

At drupa, RMGT will also demonstrate AGV for transporting paper and printed sheets to each subsequent process.

“By connecting the presses, AGVs, and postpress equipment all under the supervision of the PIC, RMGT is proposing automation and labour saving solutions for the entire printing companies,” the company said.

Smart factory solutions will also be on display, showcasing other devices and systems for the smart factory of the future.

“RMGT’s smart factory of the future responds to accelerating market trends with an ideal production system that flexibly meets changing demand. The automated labour saving presses of the future will enhance print quality and shorten make-ready times, utilising IoT and cloud technologies for real-time visualisation of press operating conditions,” the company said.

“All equipment within a printing factory will be interconnected and AGVs will relieve operators of the repetitive workload of transporting paper and printed materials to the next process.

“RMGT’s automation and labour saving technologies relieve operators from time-consuming and labor-intensive tasks and burdens, enabling printing companies to capitalise on their expertise and maximise their potential. RMGT’s vision is of a world where machines and technologies are designed around people for a higher level of creativity and efficiency.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter