Heidelberg has equipped its solutions with the most intelligent systems to enable print shops to optimise every aspect of their production.

Today’s printshops are facing increasing challenges, such as shorter run lengths, faster turnaround times, increasing costs, competition for talent and declining print prices.

To help print shops alleviate these challenges, Heidelberg has fitted its solutions with intelligent systems that control the harmonious interaction of six key factors:

1. The integration of customers

Web portals simplify communication and automate workflows. The result that print shops get is more efficiency, more customer service and in turn, more turnover.

2. The reduction of touchpoints

Fewer touchpoints and more automation unleash unrealised potential. This results in visible throughput increases.

3. The increase in productivity and operating time

Efficient planning and automatic data availability increase the operating time and productivity. This means profits for print shops increase.

4. The reduction of paper waste and warehousing

The use of optimal materials ensure reproducible production. When this occurs, paper waste decreases.

5. The optimisation of consistency and reproducibility

Standardisation provides certainty and consistency. As a result, production becomes more predictable.

6. Having business intelligence

Having insight into business intelligence delivers sound information for print shops to utilise. This means they can make decisions based on real facts.

Heidelberg’s Prinect workflow allows its customers to stay ahead and benefit from a digitised world

BENEFITS OF DIGITISATION

Digitisation offers the printing industry a great many opportunities. But anyone looking to harness these opportunities need to actively shape this process of change.

As such, Heidelberg’s Prinect Production solution reorganises the production workflow, ensuring the basis for increased cost-effectiveness, consistently high performance, and outstanding quality.

Many processes are completely automated, thus providing a smart boost to the success of a print shop.

In addition, Heidelberg’s Prinect workflow allows customers to stay ahead and benefit from a digitised world.

Two leading Australian print companies provide their comments on how they have benefitted from using Heidelberg’s digitisation solutions:

Southern Impact managing director Rod Dawson said, “Prinect gives us a lean production workflow, a consistent quality outcome, accurate repeatability, and transparency across the entire production – which in turn helps to identify any bottlenecks and uncover potential areas for further improvements”.

NEO general manager Clinton Daley said, “A print company’s workflow is the beating heart of its manufacturing process that has enormous ramifications on output – both in speed and quality.

“When it came to aligning ourselves with a business, we felt that Heidelberg was the natural fit. My family’s relationship with Heidelberg would be getting close to a hundred years. The choice of Prinect was simply a natural evolution of this long-standing relationship and we knew in Heidelberg that it was a company that would help us grow and share the same industry-leading mentality that we as a company strive to have.”

ENHANCING PRODUCTION

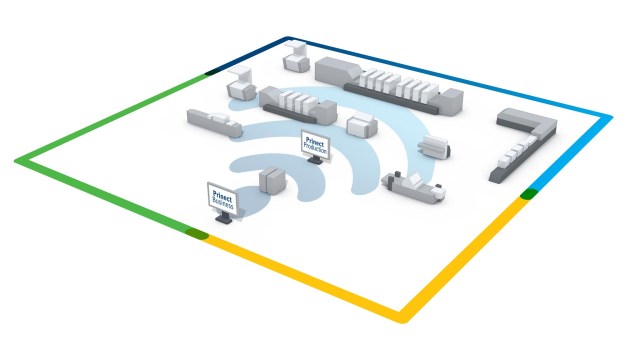

Prinect Production offers enhanced performance thanks to intelligent processes. It digitises a print shop. It addition, it automates production and colour and quality management while also providing key data for analyses and reporting. It keeps customers coming back and maximises performance with a smart workflow.

The new Heidelberg philosophy

Push to Stop is Heidelberg’s idea of a smart print production. It is based on networked processes and intelligent machines that organises and works through print jobs independently with full autonomy. The operator only has to intervene if necessary. Print shops can increase the overall effectiveness of their machines and can almost double their net productivity, enabling them to become a Smart Print Shop.

Save time and money with Prinect

For Push to Stop to become reality, new and improved processes are required that provide all the necessary production data. Prinect is the tailored solution for successfully implementing this philosophy of the Smart Print Shop with Push to Stop.

Prinect Business supports printers in the automation of their commercial processes and production. Prinect Production covers the actual production workflow – from the pre-press modules through to offset and digital press to post-press.

A decisive step that puts a printer ahead of the competition

Whether a company is small or large, or whether it is a commercial or packaging printer, Prinect reduces all touchpoints.

In other words, the process steps and manual interventions involved in order acceptance, data transfer, or post-processing is kept to a minimum.

Users always have an overview – of the workflows, the utilisation, and the economic efficiency of their print shops – and can react directly.

The perfect solution for the Smart Print Shop

Prinect Production transforms a print shop’s workflows. Manually controlled operations involving a wide range of touchpoints are replaced by intelligent networking and automated processes. Touchpoints are reduced and flexibility increased.

With Prinect Production, printers are closer to their customers and integrate them directly into the workflow. Data entered online controls processes throughout production and quality management. Digital approvals speed up production times and increase productivity. Moreover, as efficiency increases, so too does the satisfaction and loyalty of their customers.

It also lets printers reduce waste and storage through standardised quotations, perfectly coordinated consumables, and defined processes. This means printers can use their time, machines and materials more efficiently, while simultaneously optimising consistency and repeatability. Pave the way for Push to Stop by using intelligent machines that organise and work through the production process independently. With Prinect Production, most operations can be carried out based on navigated or autonomous control.

Prinect Production also makes it possible to unlock the full potential of a print shop. Integrated business intelligence functions can be used to produce reports for corporate management and production that are intuitive to understand.

Accurate data and sound analyses reveal error sources before damage occurs. Real-time data capture and evaluation ensure you are always up to date on current processes.

Printing was never so easy.

How Prinect Production increases your productivity

• Offers portal functionalities to optimise selling and communication process

• Enables powerful job setup, planning and presetting, eliminating manual intervention that keeps presses up and running

• Includes fully-automated plate production including pre-flighting, imposition and more

• Has press room and finishing integration, delivering best data to drive Push to Stop production

philosophy

• Provides significant analysis and reports, changing the way printers make their business decisions

• Offers maximum freedom with one workflow, whether a printer produces with toner, inkjet or printing plate

• Provides everything needed and much more – no matter where a print shop wants to extend its business, Prinect Production is ready for commercial, packaging and labelling.

That is Prinect – Driving the Smart Print Shop

Prinect Production Manager provides a full suite of software productivity tools that help printers attain the highest levels of productivity in their print shops through an easy monthly subscription fee. Some of the benefits include:

• Low initial startup costs that lets users take advantage of Prinect Production Manager solutions without the big upfront capex or the need for financing.

• Simple subscription model: Complex, expensive license models are a thing of the past with an easy and transparent monthly usage fee that follows a printer’s production volume.

• All the latest upgrades and new technology from Prinect Production Manager with the monthly subscription. This is safety that a print business deserves.

• Scalability of workflows and introduce new Prinect solutions into a print shop at a printer’s own pace.

• Return on investments from productivity and efficiency gains with powerful workflow tools like presetting, multi-colour, gang printing, smart automation and more.

Printshops are rapidly adopting Prinect Production Manager on the road to building a Smart Printshop. Currently, Heidelberg has more than 2,000 Production Manager subscribers worldwide, with 65 of them based in Australia and New Zealand. Heidelberg continues this growth by adding 400 new systems globally every year.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter