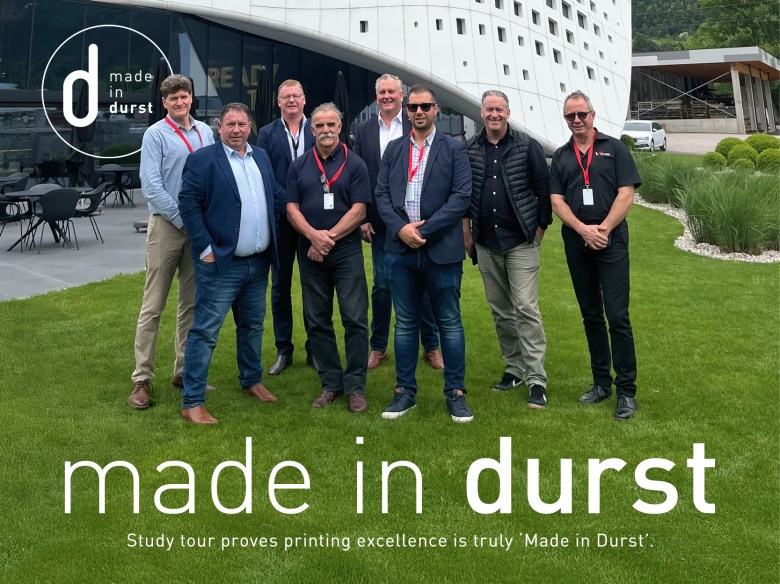

Durst Oceania recently concluded its fourth European tour – once again demonstrating that world-class printing quality, ingenuity, and innovation is truly ‘Made in Durst’.

Durst, a global leader in digital printing and production technologies, recently hosted its fourth pre-FESPA European tour – a three-day event designed to foster networking, share industry insights, and offer an exclusive preview of the company’s latest printing solutions.

The tour, led by Matt Ashman, managing director of Durst Oceania, featured a visit to Durst’s state-of-the-art headquarters in Brixen in northern Italy, as well as a cultural stop in the picturesque town of Kufstein, Austria. The event brought together industry professionals across Asia Pacific for a blend of innovation, collaboration, and European heritage.

Durst Group, a third-generation family-owned business co-owned by Harald Oberrauch and CEO Christoph Gamper, has been a leader in digital printing technology since its founding in 1929. Today, the company employs more than 1,100 people globally – an increase of 10 per cent over the past year – and is renowned for the quality and reliability of its advanced solutions across the global graphics, ceramic tile, labels, packaging, and commercial corrugated packaging sectors.

The Durst P5 Platform – Powering the future of print

During a guided tour of Durst’s headquarters in Brixen, delegates were given a firsthand look at its technologies and heard more about the thinking behind the company’s flagship solutions.

At the heart of the showcase was Durst’s extensive P5 platform, a standout example of its commitment to innovation and customer-centric design.

“The word ‘game-changer’ is used too often, but the P5 platform truly earns the title,” said Ashman.

Ashman explained that the P5 platform was developed in response to customer feedback and built to be scalable – designed to evolve with both Durst and its customers’ needs. Combining advanced hardware, hybrid flexibility, and integrated software, service, and ink solutions, it delivers a true end-to-end offering.

“We set out to create a unified platform that could grow with us and our customers,” he said.

“The P5 has been incredibly successful in achieving that. Many of our innovations are not only available now but can also be retrofitted to existing machines.”

Ashman said the recently launched P5 X marks a new direction for Durst, but it builds on the proven strengths of the P5 platform.

The new PX 5 is a ‘true flatbed’ with roll-to-roll capability to fill a mid-market position in the company’s P5 large-format printing portfolio.

The PX 5 is designed for ease of use, featuring ergonomic handling, multifunctional LED status bars, intuitive media registration with a pin system, and automated safety functions for a smooth and secure workflow. Operators benefit from a smart interface and advanced job management, supporting up to 12 independent print queues for efficient multitasking and reduced downtime.

“The P5 X complements the other products in the P5 portfolio and is the true flatbed machine that everyone has been asking for from Durst for some time. The market needs a machine like this with the flexibility, reliability and functionality that Durst customers have come to expect,” Ashman said.

AI meets advanced automation in Durst’s latest print solutions

Another focus of the tour was Durst’s increasing emphasis on software. From automation to artificial intelligence, Durst’s expanding software portfolio is designed to deliver smarter, more connected workflows.

The company’s portfolio includes end-to-end workflow solutions for seamless automation and AI-powered applications to optimise production processes.

“Our software development – and our software team – has grown at an exponential rate,” Ashman told tour attendees.

Matthias Summerer, sales management – software and solutions – Durst Group, told delegates the company is making significant investments in software development to optimise every stage of the production process.

“We recognise that software is the foundation of true automation,” he said.

“What sets Durst apart is that we’re the only print manufacturer offering a complete, end-to-end software ecosystem. Our solutions are designed to be as flexible, modular, and scalable as possible.

“Each module can be integrated not only with Durst systems but also with non- Durst systems, making it adaptable to virtually any production environment.”

Durst Lift ERP is a cloud-based ERP/MIS software which provides a single integrated platform to run every aspect of a print business. The process is automated and streamlined, from taking a customer’s order online, into pre-flight and manufacturing, and all the way though to customer delivery. Durst Workflow Plus is a fully featured RIP and pre-press software production suite.

New AI-powered tools developed by Durst are designed to enhance the processes and make technologies more performant and accessible.

Notably, Durst’s Image Tracking Tool utilises a camera or smartphone to instantly capture and identify prints in real time, ensuring seamless job tracking and enhanced process reliability.

Durst’s new AI-based Upsampling feature intelligently reconstructs low-resolution files to ensure crisp, high-quality output, even when the original file provided by the customer lacks sufficient resolution. Durst Group also recently acquired callas software, one oof the leading providers of prepress automation and PDF technologies that plays an essential role in many print workflows – either directly or as an OEM component in prepress product.

In the coming months, the collaboration between callas software and Durst Group is expected to deepen, leveraging synergies and accelerating the development of an open, vendor-independent software platform for the print industry.

Labels leading the way

Ashman said Durst is focused on delivering flexible solutions that help customers diversify into new markets – whether it’s wide-format, packaging, or labels – with labels standing out as a key area of growth.

“Labels has been a massive growth for Durst and we have some of the most advanced label solutions,” said Ashman.

Among these solutions is the Tau 340 RSC. With print speeds of up to 80m/min for the upgraded version, a native resolution of 1,200dpi by 1,200dpi and up to 8-colour stations, the Tau 340 RSC enables customers to achieve flexo like productivity in a 24/7 environment. It can be also equipped with the revolutionary Durst Hawk Eye technology to automate print quality. Applications for the machine include variable data and speciality packaging.

Further solidifying its commitment to the packaging and labels space is Durst’s partnership with fellow family-owned Italian company OMET to develop hybrid printing systems.

The jewel in the crown of the Durst and OMET partnership is the KJet, a new digital and flexo hybrid machine tailored for the label and flexible packaging market. It is the second joint development by the companies after the XJet.

The KJet combines the ‘cylinder-base dual-servo’ flexo technology from OMET with the robustness and reliability of Durst’s RSCi digital printing engine. The companies say it also offers operators a seamless experience with its user-friendly interface and ultra-short web path. This design minimises waste and reduces setup times, showcasing the advantages of digital printing.

“This partnership brings together two industry leaders, combining their strengths to deliver much-needed innovation to label converters across the Oceania region,” Ashman said.

Durst will host its next tour dedicated to label innovation ahead of Labelexpo, which takes place from 16-19 September 2025 in Barcelona.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter