Coleman Group recently added on a Durst P5 350 HS large format printer and Durst P5 TEX iSub dye sublimation printer to sit alongside its Durst Rho 325, Rho 512R and Rho P10 250 machines.

Glenn Coleman can’t remember exactly when he bought his first Durst as it was so long ago, but since then he has bought another five machines that are all operating on the floor of his event and exhibition signage business in Sydney.

“We bought our first Rho 800 in either 2007 or 2008 when Durst was managed in Australia by PES. Nine years later we upgraded to the Rho 325 and Rho 512R and that was six years ago. We also have a Rho P10 250 – and they all continue to operate today,” he said.

Last year, Coleman added more firepower to his business with the introduction of a P5 350 HS and a P5 TEX iSub dye sublimation machine. After a significant reorganisation on the floor of his factory, Coleman now has two Durst textile machines and three Durst UV machines all operating within metres of each other.

“We have found the new Durst P5 TEX iSub has been great – it can print direct on to certain fabrics and creating jobs directly is a huge advantage. We also print to paper on this machine as well. I would recommend it for people that maybe don’t want to invest in a separate finishing machine for dye sublimation.

“The P5 350 HS was a machine we loved as soon as we saw it at the Durst factory in Brixen in February 2023 after attending the Euroshop exhibition at Düsseldorf. It has been going very well since it was installed late last year.

“We put similar work through the older Durst machines as the new machines,” Coleman said.

“Our customers are very deadline driven – we just can’t not deliver – it is not an option and that is why we have Durst, why we chose Durst originally and why we have stuck with Durst.”

While some companies have only recently started seeing a move towards more sustainable materials including fully recyclable exhibition materials – Coleman claims this trend is not new.

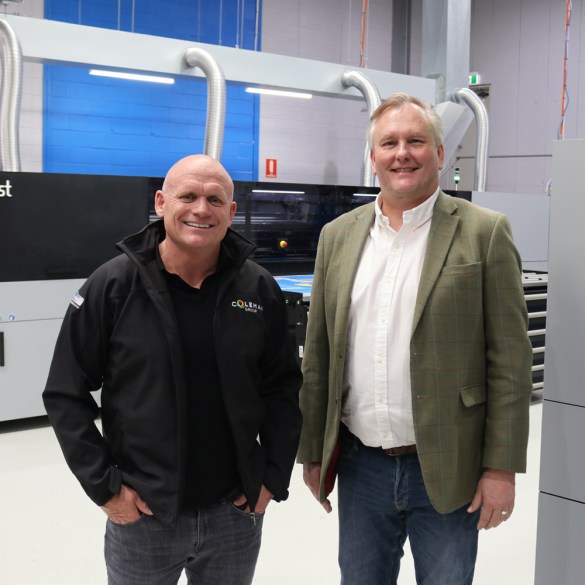

Durst Oceania managing director, Matt Ashman, is not only the supplier of machines and consumables to Coleman Group, but has also experienced what it is like to be a customer as well. “It is great to continue the relationship we have with Glenn, Rod and Coleman Group. We chose Glenn and Rod ourselves to launch Durst Oceania at PrintEx in 2019.

“Coleman Group built our stand and created all of the graphics and they did an amazing job – the entire stand was erected and installed by the team. And sometimes the concept doesn’t always meet the expectation from a design perspective – not from a printing perspective. And when it needed to be changed – it was reprinted within hours.

“They use their five Durst machines like Ferraris – and they have a superb garage featuring high performance equipment ready to go to meet a deadline.

“These machines are all top-quality examples of European engineering and Italian manufacturing that have been specifically chosen and calibrated to do a job. Even if they are not operational all day every day like other businesses, they are sitting there just waiting to be ready to win the race for not only Coleman Group, but for the customer.”

When asked if this will be his final Durst purchase, Coleman reluctantly disagreed.

“We expect to have another Durst when we upgrade again in a few years from now.”

A deep-dive into the machines owned by Coleman Group

The P5 350 HS large format printer

The P5 350 HS is a hybrid solution for roll and board printing of up to 3.5m and a productivity of up to 708 square metres per hour. Fast media change, easy maintenance handling and full safety are only a few of the reasons that Coleman Group render the printing process way more efficient.

The P5 350 HS is a fully integrated machine that makes the increasing complexity in large format printing more manageable. The printer is equipped with the Durst Print Workflow software and the monitoring tool, Durst Analytics. Coleman Group finds that the P5 350 HS provides optimum performance, from pixel to output.

The P5 TEX iSub dye sublimation machine

The P5 TEX iSUB is a dye-sublimation printer with an integrated inline fixation (iSUB) for a one step direct to fabrics printing process. The Durst P5 TEX iSub’s contactless fixing technology ensures excellent colour consistency, as well as sharpness of detail in images and text. Blurring or bleeding of colour is also eliminated.

A wide range of applications on polyester material can be implemented with the new dye sublimation printer, such as light box and decorative fabrics including difficult media as blackback and flags.

However, the printer is not limited to direct printing. Transfer papers can also be printed and further processed in the usual way – a plus for the needs of Coleman Group.

The Rho 325 direct-to-textile digital printer

With the 3.2m Rho 325, Coleman Group can utilise a dual-purpose printing system that combines direct-to textile printing with dye sublimation transfer printing technology. Depending on the application and fabric, this printing system can alternate between paper transfer and direct printing on polyester-based materials quickly.

This is possible because of Durst’s WTS printhead technology, which achieves an exceptionally high-quality print using water-based, environmentally friendly dispersion inks for various printing materials, and a print speed of almost up 390 square metres per hour.

The Rho 325 is also equipped with an integrated hot air dryer, automated nozzle cleaning system, and additional features for 24/7 production reliability.

The Rho 512R large format printer

The Rho 512R is a super-wide 12 picolitre roll-to-roll UV inkjet printer with Variodrop technology. With a print quality of up to 1200dpi and at speeds of up to 385 square metres per hour, the Rho 512R has allowed Coleman Group to print a variety of large format advertising materials by handling three 1.6m rolls simultaneously.

The Rho 512R is equipped with Variodrop technology and uses multiple impulses for modulating the droplet size.

Thus, the exact amount of ink is placed, which prevents drop satellites that are more common in conventional grey-scale printing. Unattended printing and very low production costs have also enabled the Rho 512R to be one of the most economical printers for the business.

The Rho P10 250 large-format UV inkjet flatbed digital printer

The Rho P10 250 inkjet printer enables Coleman Group to deliver quality work within industrial print production.

The printer combines speed and quality without compromising either. Furthermore, just like previous flatbed and roll-to-roll printers, its ability to print on the widest range of rigid and roll media provides Coleman Group with the ability of unrivalled and convincing versatility.

Equipped with the Durst Quadro Array 10 print head technology, this system achieves a print quality of 1000dpi without loss of speed. This also applies to the use of light colours. The compact and robust print machine for industrial production is also designed for non-stop printing with minimum downtime.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter