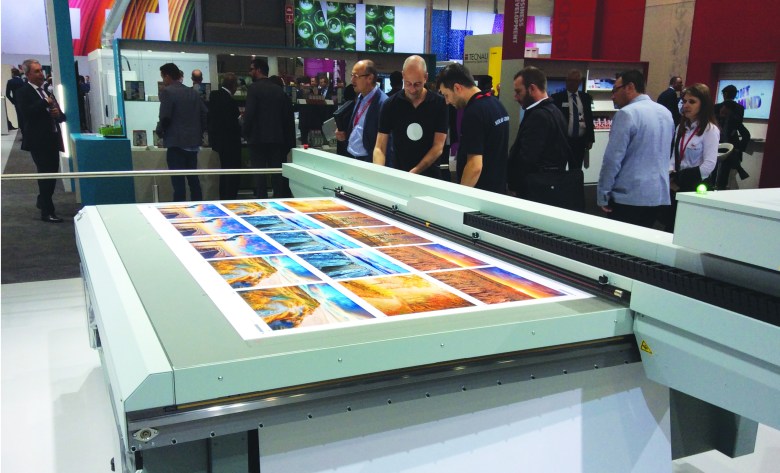

Drupa is not normally considered a display print exhibition, particularly when it follows only weeks after Fespa Digital in Amsterdam. But there was plenty to occupy a display printer wandering the aisles in Dusseldorf as many suppliers had chosen the much larger show (and additional weeks to perfect technology) to debut their new products.

The most marked development however, was the expansion of wide format inkjet technology into the printing of corrugated boards for packaging applications. There were varying interpretations for the size of the market opportunity that had driven development of machines specifically for this sector, but all could agree that is both vast and secondly, it is the market most likely to become a digital printing market.

EFI was able to announce the Nozomi, its flatbed single pass press for corrugated packaging; HP announced the C500, a first flatbed press to use PageWide thermal inkjet heads; Inca could announce a partnership with BHS, the largest producer of corrugating machines; Durst showed 2m/second printing on its Rho SPC; Bobst added two further customers for its corrugated machine and Spanish company Barberan ran its Jetmaster press.

The concept is logical: brands want to extend corporate styling and promotional print to the outer cases used to ferry home cases of say beer, that are used in shelf ready displays and are used to protect large household goods in transit. Digital means less waste and a faster time to market than using either flexo on flat sheet corrugated or else flexo or litho to be laminated to the boards.

Ultimately there are also thousands of square metres of brown material that can be decorated with advertising messages on behalf of Amazon and other online retailers. In the meantime, printing digitally can bring the advantages of short runs, late stage versioning, promotional messaging and so on to a market where lead times for flexo printed boxes have been in weeks, creating supply chain inefficiencies that digital can solve.

There are two distinct ways of producing this type of packaging. Firstly there is printing at the point of making the corrugated material or preprinted the top layer of the material. This demands wide print areas, 2.8 metres in the case of the HP T1100S jointly developed with KBA. This was too big to be at drupa. This is also the approach of BHS Corrugated Maschinen, which holds a share of the corrugating market that exceeds Heidelberg’s dominance of sheetfed litho printing. Screen will work with BHS and has created a subsidiary which will draw on expertise from Inca to deliver a single pass inkjet system to run the material at 300m/minute to match the speed of the fastest BHS corrugators. The first machine will not be deliverable until 2020, but the technology will also be available as a retrofit to late model corrugators.

This is the Formula 1 of wide format inkjet printing. At the other end of the scale are the standalone rollfed printers that are within the scope of most print shops. Roland DG hired a professional magician who supports his sleight of hand artistry with inkjet printing, including cards for a host of top name colleagues. He was one draw to the stand, another a virtual reality experience to show visitors the highly automated factory producing the machines in Japan. Among the machines featured was the new TrueVIS VG, the latest of Roland DG’s print and cut devices with faster throughput than previously.

Mutoh gave its ValueJet 1638 UH 64in printer a debut. It is a hybrid UV printer, one of many to use the cool running LED technology to improve the eco footprint and performance of wide format printing.

Fujifilm is another using LED UV diodes for its lower range machines and has introduced the Acuity 3200 UV as a 3.2 metre wide combination rollfed and flat bed printer as an entry level unit for this width. It builds on the success the supplier has had with the Acuity 1600 UV LED at half the format of the new machine.

It will go head to head with HP’s latest Latex machine, the Latex 1500. HP has shipped more than 35,000 Latex printers since the first was presented at drupa in 2008. Among these are around 500 of the top of the range high volume Latex 3000. Not everyone needs this performance, explains Xavier Garcia, vice president and general manager of the large format sign and display division, but they like the idea of the format. Hence the Latex1500 has the same 3.2 metres width of the flagship machine, but with reduced throughput and a more affordable price point.

Back at Fujifilm, the company introduced its first Uvistar model since EFI acquired Matan, which had built the Uvistar family for Fujifilm. That arrangement has not surprisingly had to end. The Uvistar 320 is the result of the new situation, a combination flatbed and roll to roll printer offering eight colour printing with the option of white, running at up to 195sqm/hr. It uses Fuji Dimatix Q class piezo printheads, includes a zoned vacuum bed and tri-lobal belt to ensure that even the lightest material is held perfectly flat while printing. It will be positioned between the Acuity machines and the flagship Onset machines that can use the same printheads.

Apart from the Nozomi machine for corrugated packaging (other applications will be addressed in future developments of this platform says EFI CEO Guy Gecht), there were no new printers from EFI. However, it has signed a distribution deal with Ricoh, initially for Latin America and Europe to be followed by North America and Asia-Pacific. Ricoh will sell EFI machines suited to its customer base, initially the flatbed H 1625 LED, in these territories. It follows on from a similar deal with Konica Minolta, and will take the Vutek machine into markets that EFI cannot reach with its own sales force.

The most intriguing announcement from EFI was the introduction of a new ink, called AquaEndure, that becomes available next year. This is a water based ink that is designed for fast drying and will initially be used for wall coverings, wraps and soft signage applications. It then be used for packaging as the components of the ink already meet the requirements of the FDA regulations in the US and Swiss Ordinance in Europe.

It joins similar ink concepts from Durst that combine water based pigments with UV curing to result in fully dry sheets ready for further processing. Sun Chemicals is also selling a similar ink, indicating a demand for a more eco-friendly ink than solvent or standard UV inks.

Ricoh’s print heads are being used in both its own machines and a number of OEMs. This does not prevent the company working with other head providers. At drupa it announced a deal to work with head producer Xaar. The two will collaborate on thin film piezo printhead development, led by the Xaar 1201 head that is suited to wide format printing. The pairing will also work on other printheads and ink applications. It will expand the range of wide format print engines under the Ricoh name. Apart from the EFI oem, its Ricoh 4100 is currently the only wide format family that is widely available for display applications.

Xaar is hoping to open up further wide format partners with a new printhead, the 5601, that is designed to be easy to integrate in a wide range of print engines, including wide format. It is the first Xaar printhead designed to work with aqueous inks.

Ricoh printheads are used in Mimaki’s Latex printers which was at drupa along with the UJV55-320 originally launched at Fespa. Its emphasis will be on the expanding applications possible with flexible and security inks. “It was about how Mimaki can support customers with future opportunities,” says Mike Horsten. “Our Design Book was a big hit, as it shows the kinds of applications Mimaki customers have developed.”

The theme stressing applications echoed throughout the show. Fujifilm had a display of different applications produced with wide format inkjet printers, including brightly coloured upholstered chairs. Agfa chose a pod-style room setting to show a range of inkjet printed surfaces. Even KBA used inkjet printed wood laminates on its stand. This had been printed on its RotaJet series machines. Kodak created an inkjet Loft to demonstrate the versatility of inkjet printing. The company has put its entire inkjet operation up for sale but nevertheless has continued to invest in its continuous inkjet technology, resulting in the Ultrastream printhead. This offers higher quality, simpler integration and a price on a par with piezo heads. Wide format printing is one target and discussions with potential customers continued through the show.

Inkjet has become one of the twin supports for Agfa’s graphics division. It had not participated at Fespa opting to demonstrate three quarter automation for the Tauro flatbed printer along with full LED curing on the Anapurna. The Tauro is now reaching the performance of the MPress machines which were Agfa’s first venture into wide format for graphics, now discontinued.

Other companies used LED to pin colours in position as they are printed, using a full mercury vapour lamp to deliver the energy needed for a full cure. The Anapurna however uses LED only. This uses less energy and means no heat reaching the substrate to distort lightweight films and other materials. The Mira printer gains a front loading roll cassette along with the flatbed table. The system means a saving in materials as nothing is wasted by being stretched over the table for printing.

If Agfa is focused on higher volume production level machines, Epson produces rollfed machines at the entry level in terms of speed, but with the versatility to print photo products to fabrics. The launch was the SureColor SC P10000, a 44in version of the 64in SC 200000.

Display print producers were also drawn to Hall 7a where Massivit was the centre of attention with the Massivit 1800, a 3D printer able to produce life sized models, up to 1.8 metres tall. These are being bought by wide format printers looking to add an extra dimension to the services they can offer with eye-catching models ansd signage which can be produced relatively quickly.

Early adopters are quickly discovering applications that range from promotional models for the entertainment industry to experiential marketing for product launches.

It was one of the standout exhibits at what was a standout exhibition for wide format printers.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter