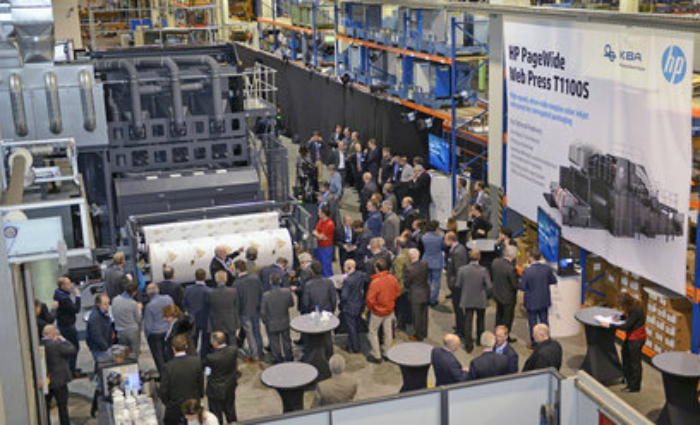

HP Inc and KBA have launched what they claim is the world’s most productive high speed digital inkjet press, with the PageWide Web Press T1100S aimed at the packaging market.

The gigantic inkjet web press with a web width of 2.80m (110 inches) was developed in under two years by HP Inc and KBA-Digital & Web Solutions in close co-operation.

The HP PageWide Web Press T1100S prints at speeds up to 183m (600ft) per minute, and produces a printed area of 30,600sqm per hour, and, say its developers, will enable packaging manufacturers quickly take on new, complex jobs at speed.

The companies say it opens up new opportunities in terms of the flexible production of corrugated packaging in various formats and run sizes with digital pre-print liners.

According to KBA and HP Inc it delivers significantly higher productivity and production flexibility than traditional analogue technology especially when it comes to small and mid-sized runs, and thanks to its high level of productivity of over 30,000sqm printed per hour it can also be implemented economically for large runs.

The move by the two industry titans is the latest development in the battle for control of the nascent inkjet packaging market, which has seen the world’s biggest offset press manufacturer Heidelberg announce it will have an inkjet sheetfed B1 folding carton press at drupa – co-developed with Fujifilm – and Benny Landa announce he is putting B1 nano presses into beta sites at the start of the year and will have a tried and tested B1 folding carton press at drupa.

However the KBA HP Inc press is the first to be webfed, although Landa has signalled nano presses will have a web fed versions.

There are certain to be other inkjet launches at drupa, and in B2 both Ryobi with Miyakoshi, and Komori with Konica Minolta, will be showing B2 sheetfed presses.

Digital printing is the fastest growing process in packaging with a projected annual growth rate of 17 per cent and is expected to be worth $19bn by 2019. Digital packaging solutions now also enable cost-effective short-runs and unlock the ability to make every box different.

“Converters and brands alike need to create more targeted, effective packaging while reducing costs,” says Eric Wiesner, general manager, PageWide Web Press (PWP) division, HP Inc. “HP Inc and KBA have combined forces to bring the world’s most productive press to market, offering more value to high-end converters with the efficiencies of pre-print and digital in one press.”

European packaging giant DS Smith Packaging is the first customer to install the HP T1100S.

“We selected the new HP PageWide Web Press T1100S as the next step in our ground-breaking digital PrePrint programme,” says Stefano Rossi, CEO, DS Smith Packaging Division. “Our co-development with HP has resulted in the first digital machine able to print at the speed and width we need for high-volume corrugated production. It will provide our customers with unprecedented short-run flexibility and quality consistency.”

While current analogue printing technology prints multiple copies of one box design in a more or less large number and all of the boxes look the same and are the same size, the HP PageWide Web Press T1100S, with Multi-lane Print Architecture (MLPA), creates an immense paradigm shift in the production of corrugated board.

Like on a highway, HP MLPA splits the web into multiple print “lanes” during production enabling different jobs, with different box sizes and run lengths, to be printed next to each other simultaneously. Multiple ultra-short or short runs in varying formats can be queued and printed together, with no makeready or press stops in between jobs, while a long run is printed in another lane.

HP MLPA, coupled with all the advantages of digital printing, allows cost-effective customisation and personalisation of corrugated packaging if necessary. It meets the demands for shorter print runs without having to create inventory. Corrugated converters can now print only what is needed, when it is needed.

As more brands demand customised and personalised packaging, converters must accommodate faster turnarounds and shorter run lengths, while producing high-quality printed solutions at lower costs.

With enhanced priming options, including a combination of HP Bonding Agent, HP Priming Agent and four-colour HP A50 aqueous pigmented CMYK inks, customers can print in a high quality on standard uncoated and coated liners from 80-400 g/m² (GSM). The inkjet web press delivers greater cost savings, versatility, productivity and quality with high colour saturation, dark black optical density and crisp text. In-line and near-line coating solutions for HP Priming Agent and aqueous overprint varnishing also help optimise print quality.

In cooperation with KBA, HP offers a range of equipment and automation options for the T1100S. These include primer and over-print varnish coating solutions, automatic reel change as well as the KBA Patras fully automated paper logistics system.

Christoph Müller, CEO of KBA-Digital & Web Solutions says, “As one of the world’s leading traditional press manufacturers, KBA has 200 years of experience in press engineering and has gathered extensive know-how in handling sensitive substrates and large web widths from offset and gravure printing. HP has played a global leading role in hard and software for 76 years and over the past 31 years has continually pushed innovation in the field of thermal inkjet technology forward. Users of the HP T1100 PageWide Web Press will profit from our joint knowledge and the synergies between both companies. We started this alliance before all contracts were finally signed, which is proof of our mutual trust, and our technical teams work together well.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter

When I first started out in print, the owner interviewing noted my resume was printed with Ink Jet. He scoffed when I told him that Ink Jet was the future. Fast forward a decade and he’s no longer in the print business.