Sprinter recently took a tour of Bailey Print Group’s premises in Salisbury, Brisbane, with its director Samantha Bailey-Jensen outlining the company’s achievements and sustainability journey.

Bailey-Jensen, who has been with the company for 23 years co-manages the business with her brother Peter Bailey, who has held the helm for 24 years. Bailey Print Group was started by their parents in 1985, on their family home’s dining table.

The company celebrates its 37th anniversary this month and has since become one of the most established print houses in Brisbane, offering an advanced selection of sustainable print solutions.

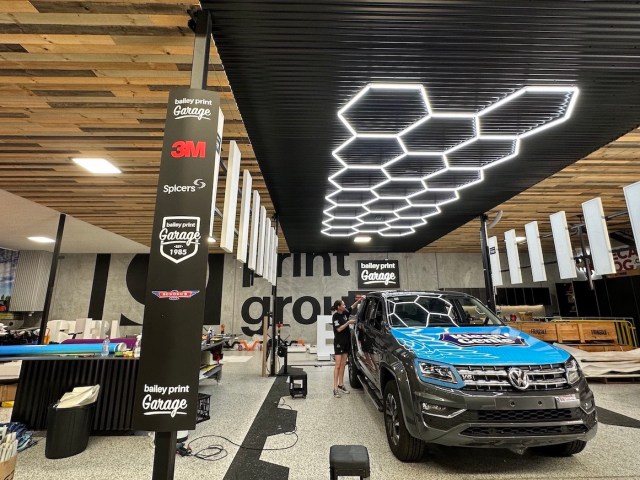

Bailey-Jensen said the company’s passion for efficiency and commitment to eco-friendly signage drives the business, and was the main factor that drove the design of its Salisbury premises. The company has been in this location for two years, and was nine months in the planning.

The location houses a HP 1500 and 3200 roll-to-roll large format printer, a R series flatbed printer that it installed last year, an Océ cutting machine, various finishing machines as well as a few other supporting machineries.

Bailey Print Group has fitted out its facility and is driving down emissions with a 264 rooftop 81.6 kW solar energy system which powers its entire operation including its HP Energy Star eco printers.

Its workplace is safer and healthier due to its use of non-hazardous printing methods and non-toxic inks, thereby improving employee well-being. The company also implements green workplace practices that reduces landfill – for example, its ink cartridges are recycled through Close the Loop, it has a dedicated recycling area in the garage, and picks up corflute from its clients for recycling.

“We go beyond just keeping ourselves sustainable. We aspire to reduce waste impact by working to recycle, repurpose and reuse,” Bailey-Jensen said,

“Our HP Ink cartridges are recycled into road base, corflute recycled into plastic strapping, vinyl repurposed by the agricultural community for weed reduction and schools upcycle items for arts projects. All other waste is sent to a Resource Recovery Centre.

“We are on a roadmap to zero emissions and will continue to advance our circular economy philosophy and work to a more sustainable world.”

This year alone, some of Bailey Print Group’s work includes the signage for the Virtus Oceania Asia Games that took place in Brisbane, 450 banners that it produced for the Brisbane Festival and several major events for the Brisbane City Council.

Bailey-Jensen said she has more plans for the company involving sustainability as it moves towards further minimising the impact associated with printing.

Here are some pictures from the tour of the premises:

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter