Pictured above: Trent Nankervis (CMYKHub), Mark Hyde (ABG), Mark Daws (Currie Group) and Paul Norton (CMYKHub)

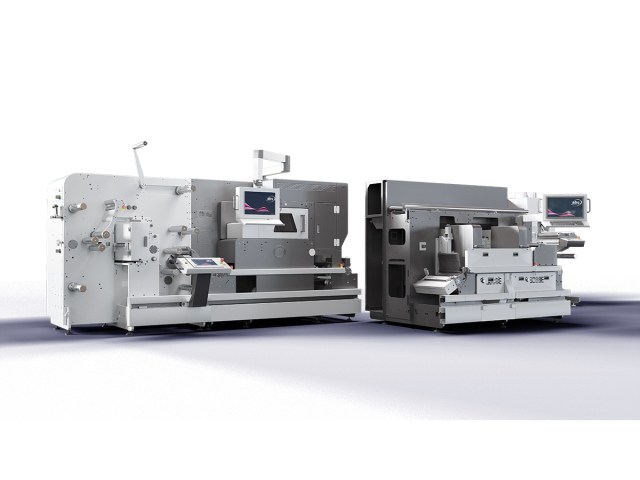

Trade print service provider CMYKhub has purchased the first DigiLase 4.0 with DigiJet 330 finishing solution from the A B Graphic International (ABG) portfolio to be installed in the Asia-Pacific region. The machine purchased through ANZ distributor Currie Group will be installed in the company’s Melbourne production facility.

CMYKhub launched its labels division in March after investing in an HP Indigo 6K Digital Press at PacPrint in 2022, which, according to CMYKhub manager for customer experience and communications Glen Francis, received “amazing” interest from customers.

Francis said, “I don’t think we’ve ever sent out so many sample kits to our resellers as we have done with labels, and orders have been growing steadily, month on month.

“As with any new product line at CMYKhub, we have introduced options slowly, building up the service as we better understand exactly what our customers want, but we confirmed almost immediately that the market for custom labels, particularly in short to medium runs, is where demand is really growing exponentially.

“Print buyers in this space demand creative solutions, produced to the highest quality standards, to achieve the cut-through and shelf appeal they need, and they want them fast.”

The challenge for CMYKhub is to meet the demand from print service providers for an array of label options but to do it profitably for its own business and provide good value and potential margin for resellers.

Francis added: “Quite clearly, the answer is digital. CMYKhub already has a growing library of dies to finish standard and some regular and longer-run custom jobs. However, with short to medium runs making up a large and fast-growing proportion of orders, expanding our digital capacity made good commercial sense.”

According to Francis, that is where the new ABG DigiLase / DigiJet system comes in. Combining a DigiJet 330 digital embellishment model with DigiLase 4.0 digital laser cutting, it provides a one-pass solution for a wide range of embellishments and customised finishes in various sizes and formats.

Francis added, “We are always looking one step ahead, and with our label production, it was simply logical to investigate what would be on show at Labelexpo. The team from Currie Group were able to share with us what ABG had planned, and this combination solution immediately stood out to us for its flexibility and productivity.

“There was simply no question in our mind that modular systems like this are the future of finished labels.”

The DigiJet component of the new line has been configured to provide multiple high-quality embellishment options – including spot varnish, cold foil and tactile screen effects – all in a single pass and with absolutely no tooling.

It handles a wide variety of stocks, including textured stocks. It can produce tactile varnish and cold foil from one foil, embellish textured stocks, apply foils of various thicknesses and apply both solid varnish and fine detail, all on the one label.

Francis commented, “It’s just so flexible. No one in the Australian label trade space is doing what this machine can do.”

The DigiJet modules are complemented by the DigiLase laser cutting unit. Specially designed for shorter runs, they can cut intricate shapes to suit an almost endless array of customised label solutions with superior accuracy.

“DigiLase is fast and fully automated, driven by sophisticated ABG Connect software that automatically calibrates the laser path, power and speed according to each material and shape, for fast and easy job set-up and changeover and optimal results every time,” Francis said, adding that the new system integrates seamlessly into the company’s pre-press partner company DFLOW’s Synergy workflow, using QR Codes to read the job workflow for fully automated job setup.

“The systems work beautifully with our workflow, providing an intelligent solution which is tried, tested and reliable. That’s important to us, as we are a busy, multi-shift production environment, so any bottleneck has a knock-on effect on the whole operation,” Francis pointed out.

Maximum productivity and efficiency, with fewer touchpoints during production, of course, results in higher throughput and – critically – maximises margins for both CMYKhub and its clients, while meeting market demand for ever-quicker turnarounds.

“Trade services is a challenging market and there’s no room for delays or inefficiency,” Francis said. “These new investments, together with our HP Indigo 6K Digital Press and existing Digicon Series 3, allow us to outperform the market on turnaround, with typical delivery times of three to four days on most jobs without compromising on quality or value.”

This is not the first ABG solution purchased from Currie Group, so CMYKhub is familiar with the range’s quality and the support provided.

Francis added, “We always look at our options; that’s just due diligence. After researching the digital finishing options in this market at various price points, we felt we had to back ourselves and our customers with the best available technology that has been tried and tested in practice.

“ABG is a leading brand; this is the fourth version of their laser technologies, so it’s proven technology from a market leader. Currie Group’s service team are fully trained to support DigiJet and DigiLase products in the market, and their service and support is legendary.

“Together, they make an unassailable team, backing a solution which will allow us to provide our resellers with the most innovative and profitable solutions on the market with absolute confidence.”

Currie Group director for labels and packing in the A/NZ region Mark Daws added, “It’s always exciting to be able to provide CMYKhub with innovative, intelligent and reliable solutions to help them meet customer requirements. We’ve been partnering with the team for many years now and look forward to continuing that relationship for many years to come,”.

Meanwhile, the latest investment has rounded out CMYKhub’s label department perfectly. It has been enthusiastically embraced by its production team, which has recently been boosted by two experienced new additions to the business, Steve Bonanno and Dean Hill.

CMYKhub CEO, Dayne Nankervis said, “We believe labels is going to be huge for our business and provide fantastic opportunities for growth for our trade partners.

“We have already been so impressed with what they have done to add value for print buyers with our range of Scodix and Metal embellished sheet-fed products, so to allow them to add value to our label range in the same way is going to be fantastic.

“We can’t wait to see what they come up with, and to discover what our talented team can do with the new DigiLase / DigiJet finishing unit to provide even more exciting options for them, and for their label customers.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter