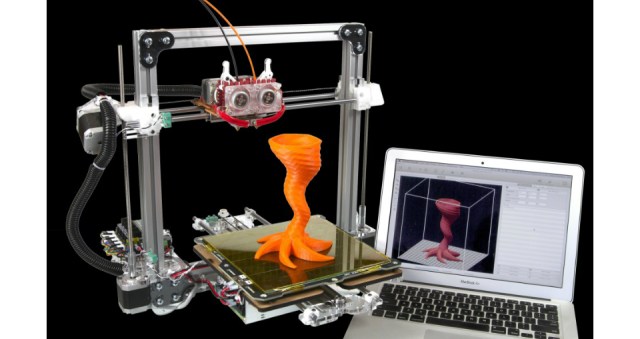

Sydney’s Coleman Group has expanded further into 3D with the installation of a Mimaki full colour 3D inkjet printer to complement the work already being done by the Massivit 1800 Pro it bought last year.

The acquisition of the Mimaki 3DUJ-553 – the first of its kind to be used commercially in Australia – has also prompted the creation of new brand, Mammoth 3D.

Mammoth 3D is being headed up by Tom Peter and Rhett Coleman (pictured), the sons of Coleman Group directors Rod Peter and Glenn Coleman.

Coleman Group stepped into 3D printing last year with the purchase of the Massivit through Graphic Art Mart at PrintEx19.

Rod Peter has told Sprinter this is the first Mimaki 3D printer of its kind to be installed commercially in Australia, with the other two at universities being mainly used to produce body parts for medical student educational purposes.

The company is looking to target the a number of sectors as the Mimaki printer can produce extremely real-life models.

“We don’t really know where we are heading with it. We have always been the go-getters out the front of the market, buying new equipment. We don’t tend to go where other people go. We go where people aren’t,” Rod Peter told Sprinter.

“We first saw the 3D technology with the Massivit and we are just trying to educate clients that there are possibilities outside the flat two dimension signs.

“What we have found with doing the work on the Massivit is a lot of people were saying ‘that’s great’ but we would like to go smaller so with the Mimaki, it is an incredible machine and it can do a full colour digital print.

“With the Massivit you print in a white finish and then you sand and spray where the Mimaki it prints a finished job.

“When it finishes printing you put it in water and that dissolves any supports and it is ready to go. The quality is mind boggling, it is very realistic.”

The other feature that Rod praised was its very simple post production finishing. All that is required is the item, once set, be dipped in a bucket of water to wash off the support structures that hold it together while it is being printed.

The Massivit 1800 Pro is designed to 3D print very large models or signage, but requires more involved finishing such as spraying to remove the support structure and painting.

The new Mimaki was purchased through Julian Sing at Headland Machinery.

Sing said the Mimaki’s colour fidelity is what sets it apart from other 3D printers.

“Anything that requires a highly realistic high-fidelity colour is the absolute ideal for this printer,” Sing told Sprinter.

“Museums, exhibition spaces, medical fields and as training tools for universities for medical lab training.

“It is able to print in about 10 million colours and when you put that up against the next best thing out there that only does half a million colours but when you are talking about skin tones and subtle differences between colour, the Mimaki can do it.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter