The skin of a lizard brought to life through tactile ink, a glitzy metallic greetings card and sophisticated security inks: all effects that were once only pipe dreams for digital printers. However, many of these digital dreams have become reality. Since the last Drupa, digital technology has come on apace, enabling applications that used to be in the domain of long-run litho work to be rolled out cost-effectively for shorter-run and personalised jobs.

Have you got a personalised mailer on which you’d like to recreate the texture of an orange skin? A gloss-marked certificate that requires only a limited run of 40 copies? That’s no problem, because between them, these digital printers are now capable of performing those applications and many more…

Security applications on the Xerox iGen4 and DocuColor

What effects can be created?

Security watermarks that can be detected without the aid of UV or infrared light can be applied to any printed product on the Xerox iGen4. Certain parts of the ticket are given a glossy sheen – an effect that, according to Fuji Xerox, cannot be counterfeited.

“It’s a visual differential when you catch it in the light,” explains production marketing manager Henryk Kraszewski. “It’s changing the way in which your eye looks at the printed image.”

The Xerox printers can also create fluorescent markings only visible in UV light, security text that is only visible in infrared light and microtext that appears as jagged lines to the naked eye, but can be checked and authenticated under a magnifying glass.

Who uses these applications?

The watermark, fluorescent and infrared text can all be used for a wide range of security applications, says Kraszewski, including tickets, vouchers and certificates. “Because it’s digital printing, the applications can be very low volume,” says Kraszewski.

“So someone might have a week’s worth of events at a club and want to give out tickets where each one has a different security code. Or the watermark may in some cases be required for a product where you only want to send out a certain amount, and you need to track and trace them.”

The microtext application is designed for printers who produce documents containing personal information such as birth certificates and personal identification papers, explains Kraszewski.

How are they applied?

The application of microscopic text as small as 1/100th of an inch high has been facilitated by overall improvements in digital printing technology, specifically the constantly improving image quality of printers, says Fuji Xerox.

The gloss, UV and infrared marks don’t require any extra inks, says Kraszewski, and are instead created using patented technology to lay down the CMYK inks at different angles to the rest of the printed product. “The beauty of the system is in the fact that you use just a standard machine, standard toners and standard papers. So it is part of the printing process itself and all you require is an additional piece of software.”

What are the advantages of performing these applications on a digital rather than litho press?

While litho can apply a wide range of security marks – such as holograms and fluorescent marks – through plate preparation, die-cutting or using additional coating units, the advantage of using a digital process is that each item can be personalised.

This comes into its own particularly with microtext. While litho presses can apply the words ‘authorised signature’ to personal cheques to prevent fraud by relying on the fact that such microscopic print is very difficult to counterfeit, digital printers can print someone’s name and address in the signature line. Or, for company and government cheques, the specific amount paid can be printed in microscopic font. This can then be checked against the normal-sized information to safeguard against fraud.

How much do they cost?

No extra click charge is paid for printing documents with these special features. The main outlay for those interested in the applications is around $2,500 for the Fuji Xerox FreeFlow Variable Information Suite 10.0 software with a Speciality Imaging Kit.

Unusual ink colours on the HP Indigo

What effects can be created?

New applications for digital presses were opened up when HP launched a white ink at the end of 2010. This white liquid toner can be used either for printing on coloured substrates, or to allow double-sided images on transparent substrates, with the white ‘ink’ being used to separate each layer of coloured image.

The Indigo range also supports a wider colour gamut than was previously available on digital presses, with an IndiChrome system that uses an orange and violet toner. This, says HP, allows digital printers to match colours out of the CMYK gamut. Or, if the client is sensitive about colour match-ing and the shade is still not in the gamut, special spot colours can be created in a special ink facility in Israel.

Who uses these applications?

The white ink is typically popular with those printers catering for clients creating high-impact products, says Niel Tilling, Indigo supplies business manager at HP in the UK. “Greetings cards, postcards and signage are often created using coloured substrates and direct mail has moved towards more personalised, high-impact stuff with more unusual colours and substrates becoming more of a focus.”

White ink is also sometimes applied to white substrates as another way of creating high-impact direct mail pieces, reports Tilling. The application also comes into its own for metallic effects. “You can’t put a magnetic or metallic ink through a digital press, but you can use a metallic substrate or foil and use the white to block out the background areas.”

Spot colours and Indichrome are used by printers with customers who are very strict about colour matching, but also by those catering for the fine art market, where the possibility of using mid- and quarter-tone greys means high-impact B&W images can be printed.

How are they applied?

The white inks and spot inks are applied in the same way as the CMYK. Tilling says it the feature is enabled thanks to the use of liquid toner instead of dry toner.

What are the advantages of doing this on a digital rather than litho press?

“If you’re running a short-run campaign, as you would for a personalised mailer, you can’t run this cost-effectively on litho,” says Tilling. “So if you want to mix white ink or brand-matching with short-run or bespoke campaigns, digital is the best option – especially when the Indigo’s quality is similar to a litho press’.”

How much do they cost?

HP Australia tells ProPrint that prices are available on application. According tho the UK’s Tilling, printers are charged no extra click-charge for Indichrome. For white ink and spot colours, there is no additional cost when using HP Indigo Label and Packaging industrial presses, whereas on HP Indigo Commercial Presses there is a small premium to pay on top of standard CMYKOVG printing.

What’s next?

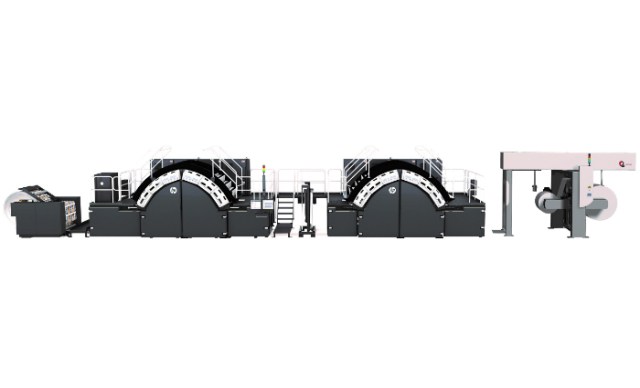

HP will beef up the special features on the Indigo range in time for Drupa. The existing range – the Indigo 5500, 6500 and 7500 – are being updated to the 5600, 6600 and 7600. The new machines will bring some funky new functions. One standout feature of the 7600 is ‘digital embossing’. The press can create a “die” by doing up to 250 passes of the textured coating to build up a raised level, which is then used to emboss other sheets.

Three-dimensional ink, glossing and security applications on the Kodak Nexpress

What effects can be created?

Three-dimensional ink used by the Nexpress can create tactile effects, such as reptile skin. The system can also apply a fluorescent red security coating only visible when UV light is shone on it and magnetic ink character recognition (MICR) inks for banking documents and cheques where there is need for ink that can be recognised by banking machines.

Who uses these applications?

The 3D inks have proved popular with a wide range of clients, says Steve Ford, sales and strategic product groups director at Kodak ANZ, who explains the effect can be used to add impact to any direct mail piece or other marketing material.

“At any point throughout the past 20 years, if you went to a printer and showed them a sample, you might think it was sharp and of high quality, but you would have seen the same thing 100 times. With a three-dimensional ink, you put that in front of them and you are looking at something new, different and exciting.”

The gloss coating is typically used, says Ford, to add a gloss finish to posters and paperback book covers.

How are they applied?

The 3D effect is created by first working with Adobe Illustrator, Photoshop or InDesign and selecting the colour that has the most tonal separation to use as an extra layer. This colour layer would be printed using the Nexpress’ fifth unit in a clear ink over the top of the colour. The ink expands when it is put through the fuser in the normal course of printing, due to the larger particle sizes of the dimensional inks.

The Nexpress’ fifth unit can also expand the press’ colour gamut and apply the gloss coating or MICR ink.

What are the advantages of doing this on a digital rather than a litho press?

Previously, a 3D effect could only be created by thermography, a system separate to the printing process, says Ford. “You would put down a special ink and heat it up in an oven-like machine, so it raised off the card. This was popular for business cards in the ’70s and ’80s, but tended to only be used for stationery because the special ink was expensive. It was also more time-consuming.”

Using a Nexpress to coat books is becoming an increasingly sought-after option, due to shorter run lengths, adds Ford.

“The book market today can go from 5,000 to one, so in this situation there’s no comparison because it’ll be so much cheaper and quicker to use a digital printer.”

How much do they cost?

Ford says there are new Nexpress solutions available in the $600,000 range, depending on the configuration.

Case studies: special effects wizards

Xerox iGen3

Australia Post division eLetter uses its Xerox iGen3 to create a postcard with a difference”, which it calls Easy Peel.

“With a revolutionary peeling solution, Easy Peel has a special UV-cured varnish that seals the card and allows it to be peeled open without damage, and transforms the traditional postcard into an expandable, fully personalised DM piece.”

“Easy Peel is a flexible speciality application that’s unique to eLetter,” says Chris Miller, head of operations & IT, eCommunications at Australia Post.

“Clients find Easy Peel cost effective as it doesn’t require an envelope and the entire printed surface can be used for promotion. It is popular across varied applications including direct mail, transpromotional and brochures.”

He says Easy Peel gives the mailer instant letterbox appeal due to the use of high-grade paper stock, the glossy finish, and the unique folding and sealing action.

Australia Post says eLetter has recently created a client solutions team, tasked with identifying new ways to leverage iGen technology to develop further speciality products, with a focus on security features.

Kodak Nexpress

Digitalpress is a five-year-old, 12-staff company based in the Sydney suburb of Surry Hills. Owner Theo Pettaras praises the new Nexpress SX3300 for some of its standout work.

“We use Nexpress dimensional raised print almost every day. It makes the print tactile. We do a lot of work for designers, and we say that if it looks good, it should feel good too.

“If you are doing a DM piece with someone’s name on it, you can use the dimensional raised print to make it stand out. It stimulates more than one sense,” says Pettaras.

He is fond of the machine’s security ink features but doesn’t use these as often.

“I have one client who uses it monthly for every event he organises. He adds security ink to the ticket. We also use it as a gimmick for DM jobs. We did one last year called Night to Shine. It was printed black, with security ink printed behind the black. The idea was shine on it with a special torch and the invitation fluoresced.”

“We aren’t in the markets that use security printing that much, such as pharmaceuticals, but our plan this year is to explore other vertical markets,” adds Pettaras.

HP Indigo

Carbon 8 is a 14-staff company based in the Sydney suburb of Alexandria. It installed an Indigo 5500 a year ago. Director Kenneth Beck says the firm is finding “more and more” reason to use the white ink feature.

“It is very handy and there is more and more call for it. Clients use it as a simple way to have something a bit different. For instance, printing simple white ink onto coloured boards is a more interesting way to do book covers or invitations. White ink on boxboard looks amazing, really white and crisp.

“We can also use the white as a base. We used it on our Christmas Card, which was printed on boxboard: we used white as the base with the other colours built on top.

“Another example was a job for Visy – an internal report. It had a boxboard cover. On the inside front, they wanted it to look like a sheet of paper was stapled in, but the boxboard was brown. So we laid down a couple of passes of white, then printed on top to make it look like a sheet of paper.”

“We also use it for clear stocks, like mock-ups of labels for agencies. We don’t have a massive demand for this but it is handy to have.”

This article includes reporting from printweek.com

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter