CANON IMAGEPRESS C10000VP

Canon says its imagePress C10000VP Series addresses the demand for the flexibility of digital output that meets offset print quality and color consistency requirements. Engineered to run a wide range of media types and weights without sacrificing overall productivity, the imagePress C10000VP Series supports a monthly duty cycle of up to 1.5 million A4 images.

The C10000 imagePress Series features print speeds of up to 100 A4 images per minute with the imagePress C10000VP, and 80 A4images per minute with the imagePress C8000VP, on all supported media weights up to 350 gsm. The Series is designed for demanding production environments at commercial printers, in-plants, transaction and direct mail service providers alike.

Canon says the imagePress produces offset-like, vibrant and stable output quality with resolution of 2400 x 2400 dpi, and comes with real-time, automatic colour control and adjustments, accurate calibration using new inline spectrophotometric sensors and Gloss Optimization technology to help match gloss levels of the printed image to the substrate it is printed on.

Dual fixing technology is implemented to maintain productivity, print speeds up to 100 images per minute on all supported media weights, serviceability improvements and extensive key operator maintenance.

Media range is from 60gsm (uncoated) and 70gsm (coated) up to 350gsm, delivering quality output even on textured media and supported specialties including vellum, film and synthetics, thanks to the transfer efficiency of the Series’ CV toner.

The versatile in-line finishing portfolio, well known with the imagePress color portfolio will comprise Canon and third party finishers including a new professional creasing module for quality appearance of half folded leaflets and saddle-stitched booklets and in general, a white-paper-in, finished-product-out workflow.

Workflow support and integration is powered by a choice of the latest Prismasync Color Print Server and Fiery-based imagePress Servers, all integrating with Océ Prismaprepare professional make-ready solution, Prismadirect job submission, order and workflow management solution and supported third party workflows.

The Fuji Xerox Iridesse is a new toner-based digital press offering speeds of 120ppm with substrates up to 400gsm, with print resolution of 2,400dpi.

The company says the new high speed Iridesse offers printers new levels of flexibility and versatility, and will enable them to increase their product range to the market.

Along with the four process colours Iridesse is able to print specialty colours including metallic with a single pass, by housing up to two additional specialty dry inks of gold, silver, clear and white.

The newly launched print engine enables CMYK dry ink layers to be processed on top of the special dry ink layer. An overlay of another specialty dry ink can be processed on top of CMYK dry ink layers, a feature made available with another Fuji Xerox digital printer, the Color 1000i Press.

Fuji Xerox says, “While conventional offset printing requires mixing silver ink to make metallic ink, this new product allows for simultaneous printing of several metallic colours during a single printing process.”

The standard colour library contains Pantone+Metallic and Pantone+Premium Metallic, which are swatches of metallic colours commonly used in the printing industry. With these colour swatches, the operator can reproduce colours similar to Pantone metallic colours on printing materials by designating the colour codes.

Finishing options include Fuji Xerox’s Finisher D6 with Booklet Maker, Crease/Two-sided Trimmer D2, and SquareFold Trimmer D1, which can be connected to the Iridesse press, allowing for automatic production of booklets and folded leaflets.

The company says the finishing options expand the possible printing applications by enabling to produce complex folded leaflets including accordion-fold and gatefold.

Roger Labrum, CGS marketing manager, Graphic Communications Services, Fuji Xerox Australia, says, “It is about personalisation for end users. Businesses should be able to align their collateral in accordance with their brand. With the Iridesse Production Press, collateral colours can be matched to brands or personalised, with colours patterned, mixed, enhanced to provide more than printed communications.”

HP INDIGO 12000 HD

HP has launched an updated version of its Indigo 12000 B2 digital press, which doubles the image resolution.

Supplied by Currie Group and based on the world’s best-selling B2 digital press the HP Indigo 10000 the new version of the Indigo 12000 has HP claiming it delivers sharper, smoother, finer print, enabling printers ‘to surpass offset quality’ and open new digital possibilities in high-end commercial and photo applications

The press uses an all-new High Definition Imaging System, using 48 parallel laser beams and high screen sets up to 290 LPI. Alon Bar-Shany, general manager, HP Indigo, HP Inc says, “HP print service providers are experiencing unprecedented growth and momentum as print buyers, agencies, and brands are looking for ways to connect the online world with the physical world. HP’s digital print technologies are blending these realities, providing new application opportunities, alongside higher productivity.”

The HP Indigo 12000 HD also features ColorUP!, which delivers an extended colour gamut using colour profiles to expand the on-press colour gamut using additional hits of CMY inks.

The B2 29-inch (75 x 53cm), seven-colour HP Indigo 12000 Digital Press is able to print for nearly any commercial application. At a speed of 4,600 pages per hour, the HP Indigo 12000 Digital Press can produce more than two million colour sheets per month. In its monochrome setting, the press can print 4,600 duplex sheets per hour for quick publishing and direct mail needs. Sophisticated automation tools also boost production efficiency and uptime, allowing users to process thousands of jobs per day. The on-press Optimizer tool uses artificial intelligence to enable non-stop printing, and the Automatic Alert Agent conducts real-time print quality error detection.

HP says that with dozens of software and hardware innovations, the HP Indigo 12000 Digital Press delivers smooth and sharp prints that match or even exceed offset quality.

The HP Indigo 12000 Digital Press supports a wide range of substrates, including canvas, synthetics, and metallised media, with One Shot technology, extending high-value opportunities. The press also enables full sheet printing to produce canvas wall art, high-impact posters, folders, oversized books and specialty products.

ACCURIOPRESS C6100/C6085

The Konica Minolta AccurioPress C6100 and C6085 Digital Colour production print systems offer colour print quality, colour consistency and performance that the company says delivers productivity for the highest digital print demands.

At 100 ppm and 85 ppm respectively, both models have been developed on a rigid solid heavy-duty frame delivering long life and robust capabilities. With average achievable print volumes of up to 480,000 prints per month and a peak monthly duty cycle of 1.8 million, these systems will tackle those large volume critical jobs when higher print capacity is required. Additionally, these models have one of the highest print speeds on SRA3 sheet size at 49 ppm and 43 ppm.

The ability to print at full-rated speed on the full range of media types from 52gsm to 400gsm duplex is a big win for real print productivity. Expanded enhancements for envelope printing are catered for with a dedicated envelope fuser unit that guarantees high speed quality envelope printing. For long sheet printing, both systems are capable of printing on media lengths up to 762mm auto duplex and simplex sheets up to 1300mm, delivering a major expansion in print capabilities that can be offered to clients. This is ideal for book covers, banners, menus and other advertising material.

With these models Konica Minolta proudly introduced the Intelligent Quality Optimiser (IQ-501) The IQ-501 uses an advanced hybrid scanning system that scans both sides of the printed sheet. As each sheet passes through the hybrid scanner information regarding colour and registration is fed back to the print engine processing system to make registration and colour changes in real-time providing consistent print quality results. These controls include colour control, toner density, front and back, and sheet-to-sheet registration, image position and centring designed to eliminate print wastage while providing assurance of print, so that print job turnaround times are reduced dramatically.

There are huge time savings with the IQ-501, as operators have easy-to-use print and set functionality for registration and colour. This automated process takes a matter of minutes saving valuable time and labour, and reducing setup times by up to 40 per cent. This increases overall print productivity and efficiency while reducing print wastage. The IQ-501 is now available the full range of AccurioPress systems.

Konica Minolta is continuing to develop new technology for digital press automation while providing the highest level of colour quality and consistency for clients.

OCÉ VARIOPRINT I-300

The Océ VarioPrint i300 is a sheetfed B3 format inkjet press, faster than high-end SRA3 toner presses but with higher quality than web-fed inkjet, and has the ability to print on uncoated offset papers, or with higher quality on inkjet coated grades.

The i300 was the first B3 sheetfed inkjet press on the market, applications were originally mainly in transactional documents, direct mail and book printing, but Océ Australia managing director Craig Nethercott says that ColorGrip will allow it to handle higher-quality work.

The company says offset press users who need image variability and automated inline finishing may also consider the i300, as it can now offer compatibility with offset papers.

It is a single-pass inkjet system with full-width head arrays of variable-drop inkjet heads. The print engine is adapted from Océ ColorStream inkjet webs, with Kyocera piezo printheads giving 600dpi resolution and DigiDot 2-bit variable drops for a perceived 1,200dpi quality.

Although it is a CMYK system there are six ink channels, with two spares. ColorGrip uses one channel to print a priming liquid. Océ may introduce special inks or spot colours in future.

Printhead nozzles are monitored and failures automatically compensated for. A sentry unit detects and diverts bad sheets.

Finishing options include the BLM600 bookletmaking system producing square-back booklets up to 224 pages thick. The Tecnau TC1530 dynamic cut-sheet perforator creates horizontal and vertical micro-perfs, with the ability to be on or off on a per-page basis.

It can print up to 300 A4 impressions per minute and can output 8,700 duplex A4s per hour on average, including cleaning and other stoppages. In offset terms, this is about 4,350sph B3.

It’s controlled through the proven Prisma controller and Prismasync digital front-end technology, with graphical user interface and touchscreen controls.

It uses drop-on-demand piezo inkjet, with water-based pigment, on paper sizes from 203x203mm to 488x320mm. The stock weight range is 60–300gsm, paper input module is 4,600 sheets per input module (two input modulesare available with maximum 9,200 sheets).

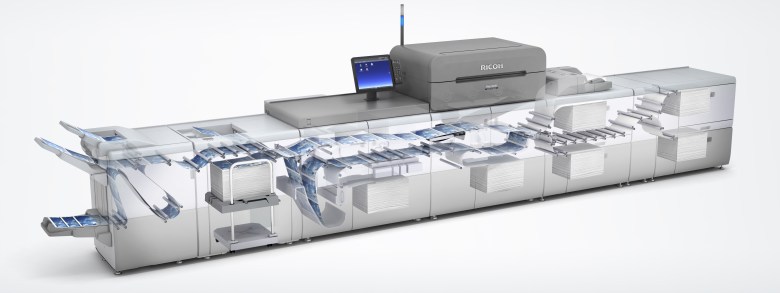

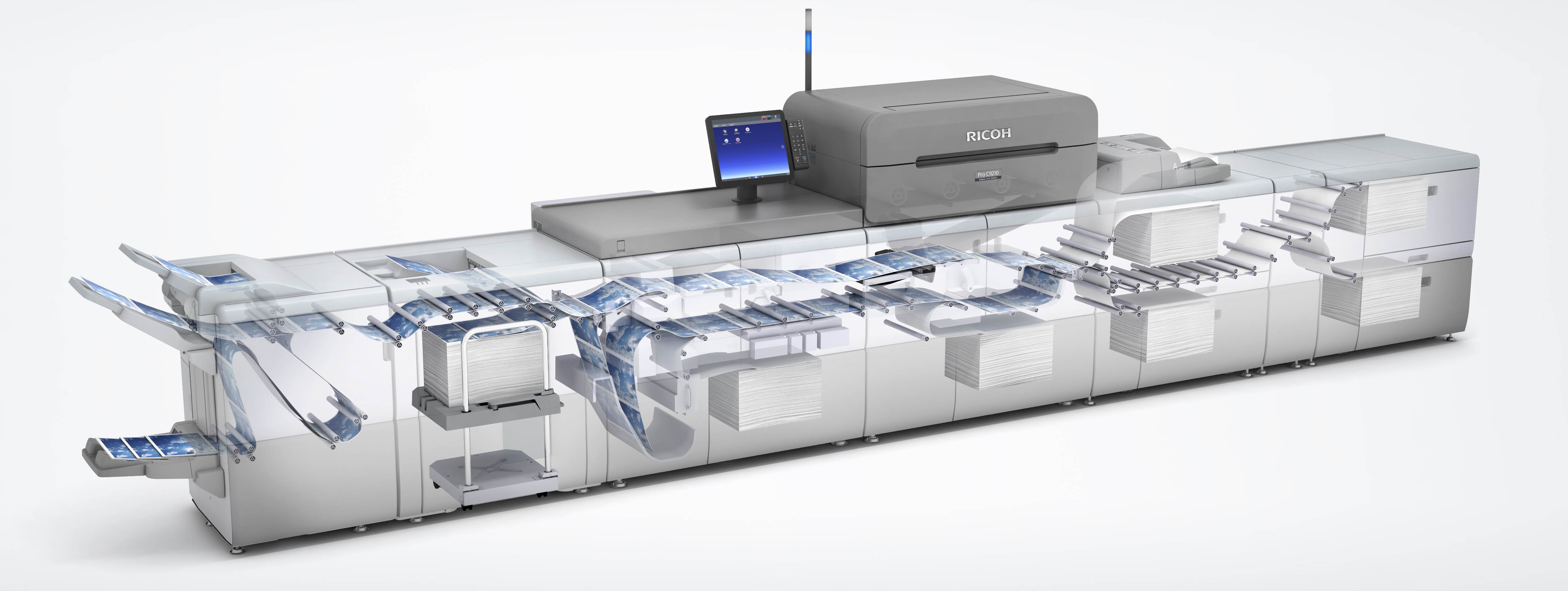

RICOH PRO C9200 GRAPHIC ARTS EDITION

The successor model to the market-leading Pro C9100 Series is the new Pro C9200 Series, Graphic Arts Edition, primarily aimed at the commercial print market. Ricoh says notable changes from the Pro C9100 Series include improved image quality and consistency, new toner formulation, higher resolution imaging, combined with a raft of image quality enhancements. The company says the new Pro C9200 has higher reliability with higher monthly print volumes, new swing-and-shift registration technology, and auto registration with real time adjustments, and new auto colour diagnosis. There is a broader media capability with heavier stock capability to 470 gsm (500 microns), auto duplex banner capability to 1,030 mm, longer simplex banner sheet capability to 1,260 mm, and enhanced NCR and envelope support. It has improved productivity with higher print speed and an hourly operating ratio of near 100 per cent.

There is greater ease of use with new, large operating panel, enhanced media library and new Media Management Tool, auto calibration, auto registration adjustment, and new jam LED guidance. New and enhanced accessories include enhanced Vacuum Feed LCIT, enhanced High Capacity Stacker, new BDT banner sheet feeder, a High Capacity Interposer, and new Plockmatic Banner Sheet Stacker. New print controllers include TotalFlow Print Server R-62 (with a choice of three PDF RIP engines for integration into Heidelberg Prinect, Kodak Prinergy, Agfa Apogee or Screen Equios offset workflows) or the EFI Fiery E-45 or E-85 Print Controllers based on the latest Fiery FS300 Pro system and new generation Fiery NX.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter