This is an extract about Kissel + Wolf Australia from the Textile Printing Technology Focus which was published in the June 2022 issue of ProPrint. To read the full story click here.

Jon Field, sales director at Kissel + Wolf Australia, says the rapid acceleration of the e-commerce boom due to COVID lockdowns and government stimulus is converting retailers to e-tailers and driving print-on-demand.

Field adds that instead of holding stock, e-tailers are offering virtual products which are then created online and fulfilled globally and delivered direct to the customer’s door.

“Brands in today’s world need to react lightning-fast to new fashion trends and digital print-on-demand,” says Field, who sees Kornit’s systems as the key to decorating different types of textiles in real time.

“Combined with eco-friendly sustainable production, waste minimisation and minimal stock holdings, many brands are able to manufacture their products with a clear social conscience while meeting fast go-to-market (GTM) products and trends.

“Australia, as much as any country, is facing change and demand for onshore production because of the supply chain disruption,” he notes, adding that Australia’s geographic location adds to the challenge.

“We have some of the most expensive water in the world surrounding us. These delays are causing chaos in markets, and consumers are seeking out brands and manufacturers where they order today and have their product delivered tomorrow. Supply chain disruption and our place on the map are a perfect storm that’s driving brands to focus their attention back to Australian manufacturing and only producing what is needed, when it’s needed, without fuss or waste.”

Opportunities for printers abound, says Field.

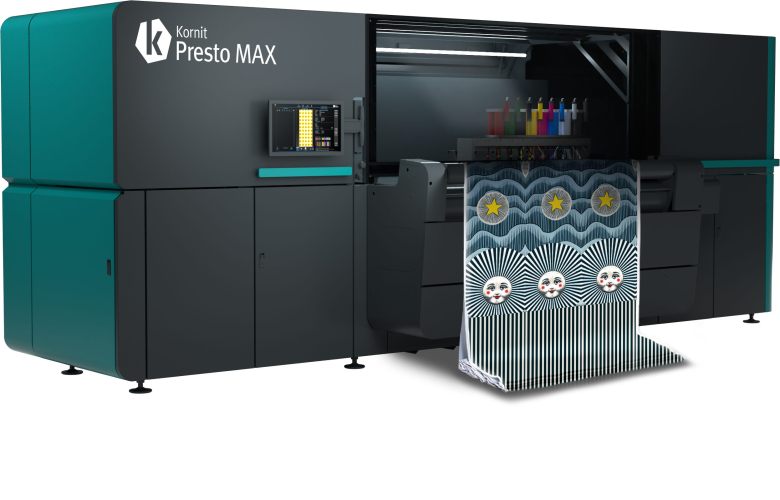

“And with the Kornit Presto utilising our pigment-based inks, this opens the door to endless textile décor applications. No speciality pretreated fabrics are needed, as the Presto pre-treats the fabrics on-the-fly. Unlike sublimation printing, which is limited to polyester, the Presto can print on a wide range of textile substrates like cotton, linen, silk, rayon, bamboo, polyester, canvas, Lycra, and more.”

Asked about the relative strengths of DTG printing, such as on-demand and personalised orders – and high-volume dye-sub printing, Field notes, “With sublimation you are always limited to polyester substrates or products coated with a poly primer for the sublimation inks to bind to.

“The largest downfall with sublimation is that there is no white ink and this is where DTG printing fills the gap. Decorating on dark or black shirts is now made possible with Kornit DTG systems, utilising our white pigment ink combined with our CMYK- plus-red-and-green coloured pigment inks to achieve a larger gamut than our competitors.”

For more information, visit Kissel + Wolf.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter