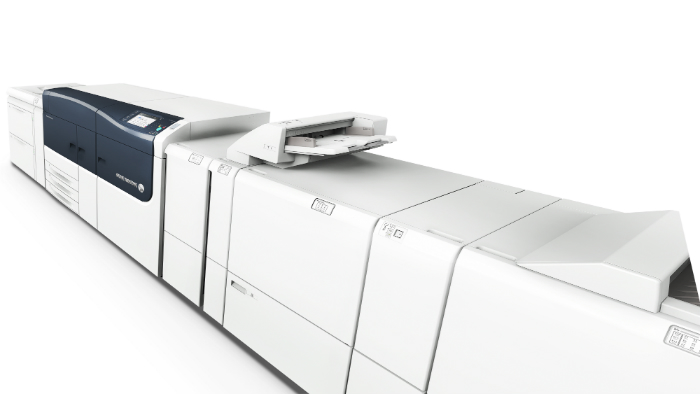

Fuji Xerox has released the new Versant 3100 and Versant 180, both designed to enable end to end print and finishing for multiple products.

Mark Brown, marketing manager production technology, Fuji Xerox says, one of the major features of the new Versants is their ability to finish various products inline.

“There are new features around the finishing abilities for customers to leave labour input and have as many applications to do inline without touching,” he says.

Brown says, “Building on the success of the Versant platform, these presses are engineered to provide whole of job capability and greater efficiency when it comes to varied finishing needs of print providers.

“The new presses are a total print solution that include simple affordable in-line finishing and all in one booklet making to automate processes, reduce costs, and ultimately streamline operator workflows,” he says.

Fuji Xerox says that with the addition of the Finisher D6 with Booklet Maker, Crease/Two-sided Trimmer D1 and SquareFold Trimmer D1 to the presses, the process of creating high quality booklets is simplified through increased automation. Brown says, “With fewer touch points and less intervention, the conventional method of manually setting up margins and placing images is no longer an issue.”

[Related: Fuji Xerox to supply screen flatbed]

Brown says “The new Versant presses are for anybody looking to save labour. These models would be for commercial printers or those who are in the non-print for pay market for example, real estate agents. The presses print on a whole range of coated and uncoated mediums, paper, synthetic material, adhesive, magnetic and 350gsm.”

The new Versants – which succeed the Versant 80 and 2100 – have a comprehensive range of features including stacking, stapling, cover page insertion and paper folding, allowing printers to offer a full range of services in one press.

Both print with a 2,400 dpi resolution. The Versant 3100 press is capable of printing at 100 ppm, extensive paper handling capability ranging from 52 to 350gsm, and automatic image control with the in-line sensor reducing operational load.

The Versant 180 delivers a print productivity of 80 ppm and extensive paper handling capability also with stocks ranging from 52 to 350gsm.

The Versant 3100 and 180 is equipped with the latest rip technology for Adobe PDF print engine 3.9, its finer gradation can be printing as well as providing improved operability, accelerating the print on demand procedure through improved image quality and operational efficiency.

Brown explains the importance of workflow with the new presses.

“One of the underestimated things in a press is workflow. Automating is how to choose and what to do with the files. It uses rules based automation with Freeflow core,” he says.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter