The printing world was once very simple: there were one-up, two-up, four-up, eight-up, and larger-format offset printing presses. The more pages you had in the job and the longer the run, the more likely it was that you would opt for the format that met your needs. Colour printing mandated longer runs because the set-up time (makeready) was an hour or two. When the first direct imaging (DI) press was introduced in 1991, typical makereadies were over an hour. The DI was then at 20 minutes and, over time, it came down to under 10 minutes. Today even older presses are near 30 minutes for makeready and newer presses are about five minutes.

A run of 500-1,000 copies is the new break point between short run and ‘not short run’ – the offset litho press manufacturers have moved the bar. Heidelberg says 35% of jobs are in the range of 250 sheets, and in this area, digital printing has had the advantage. Over one-third of all jobs (no matter how many pages) are in runs below 250. And this category is growing.

Printers report that 10,000 to 50,000 runs on their sheetfed presses are rare. There are still some jobs in that run length range, but they are harder to find. All run lengths are shifting downward as print buyers specify shorter runs – and often re-printing the job, perhaps multiple times – in place of one longer run.

When you consider that print on demand (POD) is still the primary application for digital printing, press makers with new highly automated presses have a renewed opportunity for a market that is moving to shorter and shorter runs.

The DI presses and CTP with new automated presses have shifted the paradigm. Newer DI presses are excellent choices for short-run colour printing, but the overlap between digital colour printers, DI colour presses, and larger offset litho colour presses has confounded printing company owners.

Larger-format digital presses are not to be confused with wide-format printers for signage and such. It is a new breed of printer-press that applies inkjet to sheetfed four-up sheets.

The first roll-fed digital colour printing product was the Xeikon, which could print 508mm-wide by virtually any length. The largest current cut-sheet digital printing product is the Xerox iGen4 at 364x660mm. The Kodak NexPress SX is at 356x660mm. Both are toner-based.

Screen describes its inkjet Truepress Jet SX as A2 format (420x594mm) but its maximum paper size is actually larger. Fujifilm describes its soon-to-be-launched Jetpress 720 as B2 format (500x707mm).

Sheetfed devices allow faster changes in substrate where roll-fed devices require more time to change paper. Large-format sheetfed allows the printing of larger applications (like posters and covers for POD books) and also brings with it the promise of additional productivity through multi-up impositions.

Why larger format?

Digital printing does not need a larger format to achieve higher levels of productivity for many printed products. A basic feature of digital print is electronic collation, which means that printers do not always have to produce multi-page impositions to gain productivity. Vendors have tended to sell multiple devices when additional productivity is needed, rather than developing larger-format devices that would provide more productivity within a single system.

But commercial litho printers are accustomed to a signature that prints four or more pages at one time.

Sometimes a small increase can make a big difference. For example, it may allow an additional row or column (for postcards or business cards) to enable an application that almost fits within the previous format (or allows enough room for a required bleed or trim). Sometimes it is a combination of increased productivity and expanded application fit that makes the difference. For example, in imperial measurements, one 8.5×14-inch self-mailer can fit on a 12×18-inch sheet, but two can fit on 14×20-inch sheet.

As sheet sizes increase, so do expectations associated with offset presses of that size. A five-colour plus coater press can print spot colours on the fifth unit, with a high quality level, broad substrate capability, inline coating for gloss and protection, high speed (10,000-plus sheets per hour, which is 170 sheets per minute or 1,000-plus A4 pages per minute), and low cost per unit for longer runs. Offset presses also last for decades and the major ongoing expense associated with them is the cost of plates. Thus, the large-format digital press is challenged by smaller format sheetfed and roll-fed presses as well as offset lithographic advances.

Three vendors now have announced cut-sheet simplex production colour inkjet printing devices in B2 or “large format”.

Agfa M-Press

The M-Press high-speed flatbed inkjet press has been co-developed by Thieme and Agfa for digital printing. The M-Press Leopard is designed to target the mid-sized print service provider whose output requirements are 200,000-500,000m2 of print per year.

The Agfa M-Press Leopard produces accurate registration at sizes as small as A3, thanks to 29 lay-on pins, which align the material. The design of the vacuum bed includes 55 separate zones for optimum hold-down. Lighter media is aligned using the front pins while, to maintain optimum stability, a series of rear lay pins is used to hold heavier substrates in place.

Agfa’s variable droplet technology results in fewer passes being required to achieve the required quality. Its UV ink drop sizes range from 10 picolitre through to a maximum of 26 picolitres. With a maximum print size of 1.6×2.6m, it can work with flexible and rigid materials up to 5cm in thickness. Maximum print speeds for the Agfa M-Press Leopard are 483m2 per hour and, even in photographic quality mode, the machine achieves 283m2 per hour.

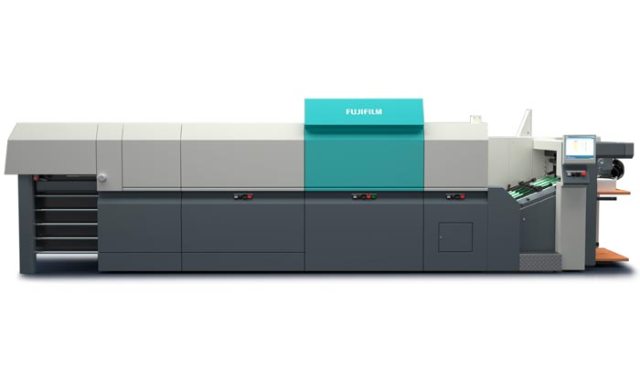

Fujifilm Jet Press 720

Fujifilm has developed inkjet technology that enables high-quality, high-speed printing on large sheet sizes (720x520mm) at high resolutions of 1,200dpi at four-level grayscale by using single-pass inkjet printing. In addition, it achieves quality levels comparable to offset printing for a variety of different types of coated papers.

The device uses Samba printheads

from Fujifilm’s Dimatix subsidiary, manufactured by Fuji Xerox and marketed by Fujifilm and/or Fuji Xerox. The amount of short-run print is increasing in the commercial print market. In general, digital printing has been the preferred technology for such short-run print thanks to its lack of makeready time. Up until now, there has been no digital print technology that achieves production speeds comparable to offset printing on larger-format sheet sizes.

The inkjet print head technology developed by Fujifilm Dimatix incorporates high-density, long-life piezoelectric element arrays with high precision and can print high-resolution images using single-pass inkjet technology at the high speed of 180 sheets (A4-size equivalent) per minute.

The press uses water-based inks, which enable bleed-free, high-quality images to be produced on a variety of coated printing papers by anti-curling and rapid coagulation ink technology. Each nozzle can jet four-level drops. Piezoelectric elements expand and contract when voltage is applied. Piezoelectric method refers to using the piezoelectric elements to change the shape of the pumping chamber where the ink is filled to release the ink. This allows high-precision printing by combining four different-sized dots (no print, small, medium, and large).

Screen Truepress Jet SX

The Truepress Jet SX features a newly developed single-pass printing head assembly that offers a combination of high quality and high productivity, and it is capable of output quality as high as that achieved by ordinary offset printing presses. It can output on A2-wide size paper, up to 530x740mm (output size maximum: 520x730mm).

The Truepress Jet SX is the first sheetfed printer of its size that can print not only on inkjet printing paper, but also on ordinary printing paper and thicker stock. The Truepress Jet SX offers overprinting onto offset printed products with no deterioration in quality, so it can be used in workflows that add POD technology to the traditional printing process.

The Truepress Jet SX runs at 1,600 sheets per hour. It is capable of running at faster speeds and can print on both coated and uncoated paper. Screen has also developed new single-pass inkjet assembly technology. The 600dpi UV head prints at resolutions of 1,440x720dpi with a media thickness 0.1-0.4mm.

The Fujifilm press is constructed around a Ryobi offset press chassis for the paper transport, where the Dainippon Screen press is a new design. Both are single-sided presses that require the paper to be printed twice for duplex printing, but Screen announced that the TruePress JetSX will have automatic duplexing. Fujifilm is targeting digital and offset presses in the range of 200 to 2,000 impressions.

Most digital printing volume consists of short-run static materials. Versioned and personalised volume is growing. Presses and printers will follow the route of the offset press and will evolve into sheetfed and roll-fed versions and all will find their niche over time.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter