What does the product do?

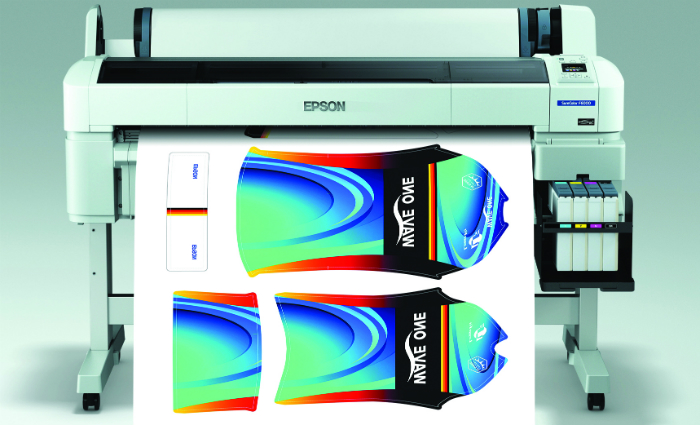

The 44in SureColor F6000 is part of Epson’s new SureColor F series dye-sublimation range (the F stands for fabric). The company claims that with its first foray into dye-sub it has re-invented the process by designing a printer from the ground up to deliver “superior image quality and improved operational reliability.” The F6000 can produce a range of different applications, including soft signage, fabric production (clothing and material), surface treatments (kitchen cabinet doors, wall panels, table tops, bedheads) and merchandise (custom covers for phones, mouse pads, mugs and pens).

When was it launched and who is it targeted at?

The machine launched in late 2012 in China and is being pitched at screenprinters, sign shops, promotional companies, commercial printers, quick printers and photo labs.

According to Craig Heckenberg, business unit manager for Epson Australia, the company decided to branch out into dye-sub after recognising the steady migration from traditional analogue printing systems to digital systems in the textile printing industry. Demand for dye-sub inkjet printers is expected to gather pace in coming years.

“By providing a better, more reliable and more integrated dye-sublimation printing solution we aim to capture a significant proportion of not only the growing textile market, but also opportunities in the sign and display and promotional merchandise market segments,” explains Heckenberg.

How does it work?

First the image is printed onto a sheet of transfer paper using Epson’s MicroPiezo print heads and the company’s new UltraChrome DS ink – Epson claims this combination delivers “amazing image quality and accurate colour repeatability.”

The image is then transferred to a polyester fabric using heat to vaporise the ink. “Once transferred the ink is stable with excellent light and wash-fastness. It is resistant to damage through exposure to alkaline and acid perspiration,” says Heckenberg. The machine uses the same basic technology as the Epson SC-S and SC-T series machines, which also launched in 2012, though the print heads have been adapted for dye-sub inks.

How fast is it?

The low to medium volume F6000 has a top production speed of up to 30sqm per hour, depending on the application. The F series also features a mid-high volume 64in SureColor F7000.

How easy is it to use?

Because it is similar to other printers in the Epson range, the manufacturer believes that existing customers should be able to use the machine straight out of the box, with minimal training required. The combination of single-operator media loading and set-up, coupled with an intuitive LCD control panel, serve to heighten its user-friendliness.

What support is on offer?

Epson provides a two-year extended warranty with a nationwide service coverage package.

How much does it cost?

It all depends on configuration, says Heckenberg; “The solution starts from $12,000 up to $15,000.” The F6000 ships as a complete production solution that includes hardware, ink and rip software. Customers will also be offered a range of optimised transfer media designed specifically for the SureColor F series.

What’s its USP?

“It is the only 44in wide dye-sublimation solution on the market today, where all components (hardware, ink, media, software) come from one single vendor that is covered by a manufacturer’s warranty,” says Heckenberg. He adds that its wide colour gamut, which enables ultra-vibrant colour reproduction, and its high productivity levels, makes it the best in class option.

What’s the sales target? How many are already installed?

The machine started shipping in Australia in September, but Heckenberg refuses to divulge details on how many installations the company has already made or how many orders have been placed to date.

He says, “Interest levels are strong from sign shops, screenprinters, commercial printers and promotional companies.” Although he refuses to specify sales targets it is clear he has high hopes for the machine.

“We expect the SureColor F6000 will greatly improve the quality of products produced by dye sublimation,” he says.

“We also expect that the SureColor F6000 will expand the reach to other potential users of dye-sublimation – now that they can have the peace of mind knowing their investment is protected by a factory warranty and that all components are designed to work together out of the box. No more messy set-ups.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter