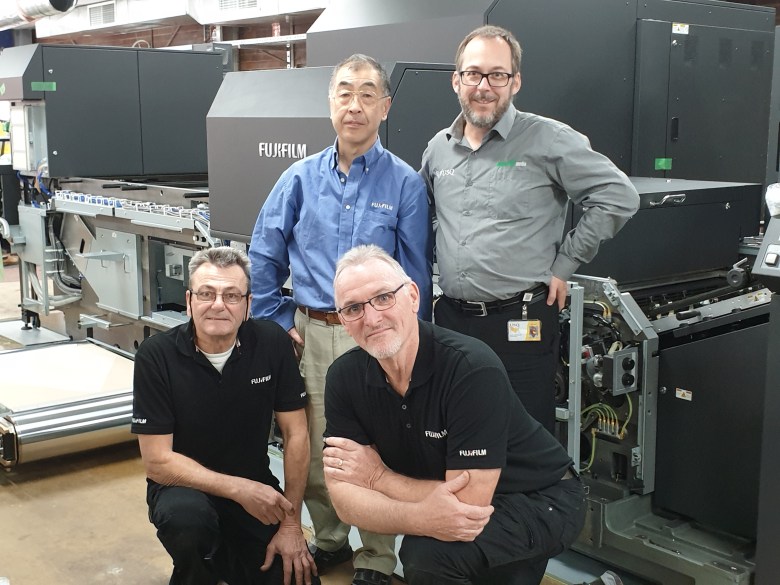

USQ Ellipsis Media (Ellipsis) has made a substantial investment in digital print, as the first company to adopt the Fujifilm Jet Press 750s, currently being installed at its print site in Toowoomba.

As the printing division of the University of Southern Queensland, Ellipsis runs on a competitive neutrality model, so as to support local businesses. By operating commercially, Ellipsis offsets the cost of the University’s print work.

With the process having begun last week, director Rob Keanalley expects it to be operational by the end of July, a staggeringly short time for a high-speed digital inkjet device capable of handling a mammoth 3,600 B2 sheets per hour.

In explaining why he made the choice to go with the Jet Press 750s, Keanalley notes, “There are a lot of printeries in the area that operate A2 offsets, we use A3. By investing in an A2 offset press, we would have been cannibalising existing market share, lowering the value of everyone’s work.

“We looked at other options, national trends, and saw that long runs were decreasing in size and market share, but short-run personalised digital was increasing.

“So what is an asset that no-one has, that gives greater share for the market as a whole? This pushed us to large-sheet size digital inkjet, we looked at what was on the market, and decided the Jet Press was the one for us.”

With a backlog of work from local printers ready for the device, the plan is for Ellipsis to become a trade-printing hub for the region, eventually servicing the entire state of Queensland.

In Keanalley’s words, “We are not only growing our business, but focusing on trade printing, helping the printers around us. It increases their product portfolio, increasing their margins and helping them grow.”

Fujifilm has said the target for the Jet Press, which features an offset chassis, is not the toner-dominated, on demand market where runs of ones and twos predominate.

According to Fujifilm, it is highly competitive for print runs up to 5,000, allowing it to compete with offset presses in the production of high quality, short run print jobs.

Keanalley has already seen this in action, with one Brisbane glossy publication that ordinarily specifies offset printing now ready to change over to the Jet Press, after seeing samples.

“They said this is perfect, we want that. For short-runs of a couple of thousand, that quality is there, but it is $2000 cheaper for them to run on the Jet Press than your offset,” he says.

“Even taking shipping costs into account, it still comes out cheaper for businesses across Queensland.

“On our side, we save on operator time, it can run without involvement, while investing extra time on the prepress side with the Jet Press saves us time in the bindery later, as the product comes out collated.

“It also frees up our offset and other digital assets to focus on work that is better suited for them. It is the third point in the triangle in terms of capability.

“With a 1200dpi and huge colour gamut it has a quality range that is unsurpassed by digital devices. This makes it perfect for local government, museums, art galleries, schools. We can produce high-quality work with the advantages of digital.

“It saves local printers the risk of such a large investment. They can grow their business by us having these capabilities.

“It delivers on the University’s strategic objective of being a responsible business partner of choice.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter