Heidelberg says its new generation of offset presses are based on its ‘Push to Stop’ concept, which essentially relieves human beings of the need to be involved in the manufacturing process.

The digitally integrated presses will not only be fully automated, they will operate as autonomous self managing manufacturing units, handling everything from planning the production schedule to ordering the consumables to predictive monitoring of service issues.

Heidelberg says the result will be a serious upswing in productivity, in fact it is predicting a doubling of print output as a result.

The ‘Push to Stop’ concept is available for the new generation Speedmaster, covering the series XL 75, CX/SX 102, XL 106 and XL 145/162, which are equipped with the Prinect Press Center XL 2, the Wallscreen XL, and AutoPlate Pro or AutoPlate XL 2 and Inpress Control 2 automation components.

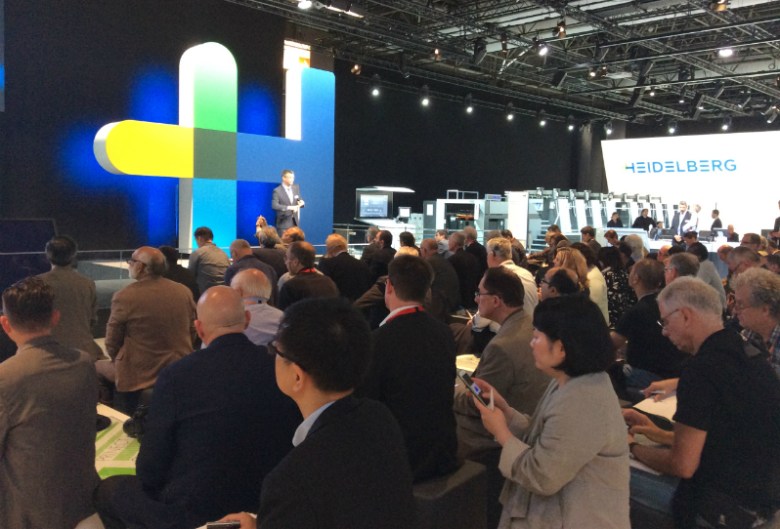

Chief executive Dr Gerold Linzbach told the world’s media that this drupa is the first birthday of the new Heidelberg, which he says has adapted to the changed world – he called it ‘a lot more complicated than when speed was the main factor’.

Linzbach says Heidelberg will develop ‘Smart Printing’ systems which will harness the power of digital integration to deliver new print systems for printers.

[Related: News from drupa 2016]

Stephan Plenz, Board member for equipment at Heidelberg says, “With Push to Stop, industrialised offset printing with maximum net productivity becomes possible. This operating philosophy will also be used in digital printing on the Primefire 106, making highly industrialised digital printing achievable for the first time.”

Launched at the show is the new Heidelberg Primefire 106, the world’s first digital inkjet sheetfed B1 press, developed in co-operation with Fujifilm. Plenz says the Primefire is not a press, but is part of a printing system.

Heidelberg says the Primefire 106 enables packaging printers in particular to take the first step in developing new areas of business, for example with the production of variable or personalised packaging.

The digital printing system offers a number of highlights, including the highest quality of 1,200 x 1,200 dpi at a printing speed of up to 2,500 sheets per hour, achieving production volumes of up to 1.5 million sheets per month in future productivity modes.

The seven-colour inkjet system with Heidelberg Multicolor technology covers up to 95 per cent of the Pantone colour space.

At the same time, water-based inkjet printing meets strict environmental and recycling requirements and therefore also permits food-safe production.

For the first time Heidelberg is sharing hall 1, with a plethora of partners also on the floor, as part of what Linzbach says it s its new policy of openness.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter