The manufacturer used its pre-Drupa press conference in Israel to announce major updates to its Print Module Solutions offering.

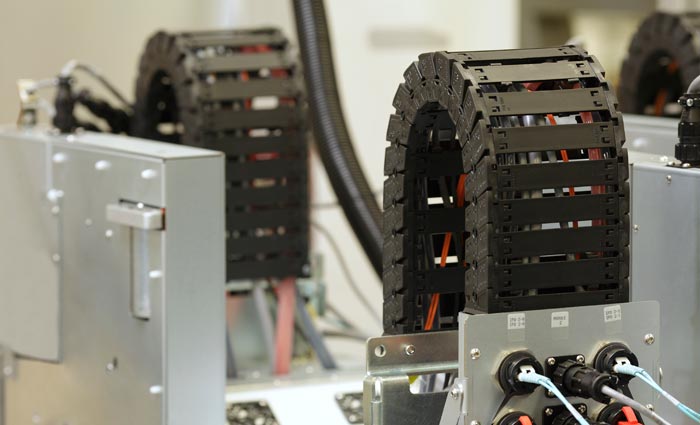

These inkjet units are retrofitted to conventional web printing lines to offer hybrid offset-digital production, allowing single-pass variable overprinting of offset shells in one pass.

HP’s move represents a full-blown offensive on arguably the one area of inkjet where Kodak is clearly more dominant – the imprinting market.

Kathy Tobin, general manager of HP’s Specialty Printing Systems division, conceded that the imprinting market was still led by Kodak, which claims to have hundreds of its Prosper inkjet heads installed worldwide and has announced new imprinting machines for Drupa.

HP’s new modules can hit speeds of up to 244 metres per minute in colour and mono, which it said would be a key selling point against the Kodak products.

Another factor setting the HP devices apart from alternative technology is that the four-colour model has the same footprint as the mono version, and can be easily upgraded, said Tobin.

Meanwhile, HP will also use the Germany trade show to unveil the latest upgrades to its standalone inkjet web presses.

Aurelio Maruggi, general manager of HP’s high-speed inkjet division, said the “bus-sized” inkjet concept press HP showed at Drupa 2008 has now turned into a tried-and-tested reality, with 60 machines installed worldwide.

At Drupa 2012, the range will be upgraded to the T410 and T360, which raise top speeds by up to 25%. Existing T350 and T400 can be field upgraded to offer the higher speed.

Maruggi was bullish about the opportunity for the technology and critical of claims from rival manufacturers.

“We have promised things to the market and we take our promises very seriously, especially to customers, who are taking a big risk.

“Many times in the graphic arts industry there has been hype about new technology that were going to transform the industry… throughout the past four years, we have seen a lot of this hype from our competition,” he added.

Maruggi said speed wasn’t the only improvement of the new range of inkjet webs – HP has also devised a new thermal printhead technology that allows rounder-shaped droplets, meaning sharper images.

He said the new droplets were more like “cannonballs” rather than “elongated sausages”.

Maruggi also stressed that it was HP’s philosophy not to let early adopters lose out if rival printers waited to invest in newer models.

He said that US-based O’Neil Data Systems installed the world’s first T300 and was the first to get upgraded to the T350.

O’Neil Data Systems now runs six web presses, and recently hit a milestone of producing 4.9 million pages in a single day on its T400.

In the signage and POS sector, HP has added white ink capabilities to its Scitex range.

The FB225 white Scitex ink is designed to work with the company’s recently launched FB225 process colour Scitex inks, which can be used on the FB7500 and FB7600 industrial flatbed printers.

At Drupa, HP will also show a new automatic loader from manufacturer Hostert designed for the Scitex presses, which it said would raise productivity. Both the ink and loader are field upgradeable.

HP also revealed a host of new additions to its Smart Stream workflow products.

For instance, it has developed web-to-print technology from Germany MIS firm Hiflex, which it acquired last year, with an online ordering portal aimed at signage printers.

The product announcements followed news of HP’s major overhaul of the Indigo range, with new B2 format presses and upgraded versions.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter