This article first appeared in the November issue of Australian Printer.

At drupa 2024, HP reflected on its commitment to leading the transformation of the printing

and packaging industry towards a profitable future. The event exceeded expectations, highlighting a significant shift in the digital versus analogue debate.

There was a clear emphasis on automation and digitisation, with HP’s Intelligent Automation (IA), giving printers and converters the confidence to seamlessly integrate digital and conventional technologies.

HP’s focus was on exhibiting how its digital transformation, powered by Inkjet and LEP/LEPx technologies, the PrintOS platform, and its extensive partner ecosystem, facilitates the smooth operation of integrated processes, leading to more responsible and profitable factories.

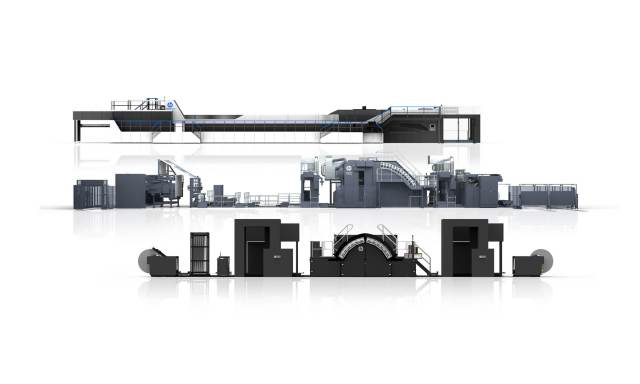

At drupa 2024, HP showcased IA across eight production lines, addressing key customer challenges such as labour shortages, energy consumption, waste reduction, mass customisation, and on-demand production.

It demonstrated how its Intelligent Production lines, operating 24/7 within a smart supply chain, will secure a promising future for brand owners, printers, and converters. HP’s cloud-based PrintOS infrastructure, including the newly accessible PrintOS Site Flow for non-HP equipment, exemplifies the future of print production.

At drupa 2024, HP questioned attendees if they could imagine a future where their entire production floor is fully connected and monitored. This includes the automation of their operations with minimal touchpoints, colour calibration, and morning routines.

And HP was not addressing the standard automation – it was talking about IA (not to be confused with AI). IA differentiates itself as automation that not only acts, but also thinks. It makes decisions based on data analysis. IA can fully integrate into a user’s current production, whether large or small, and flexo or offset. It will help a user overcome challenges they face and transform their whole operation into intelligent factories.

The intelligent factory is based around three main principles: innovative printing technology, which is the core of the industry; strategic partnerships with leading vendors in the industry; and intelligent automation.

Forward-thinking confidence

The shift from mass production to mass customisation reflects a critical demand from brand owners. HP’s booth demonstrated innovations that are answering this need and pushing the boundaries of print production.

“HP’s AI and robotics-enhanced production lines, now commercially available, validate our ability to turn vision into reality,” HP industrial print senior vice-president and division president Haim Levit said.

“Our innovation, powered by productive and flexible production lines, successfully demonstrated the shift from low-cost to low-risk supply chains, on presses like the HP Indigo 120K, V12, 200K, and the HP PageWide Advantage 2200, all of which are connected to finishing equipment for non-stop operation.”

The HP Indigo V12 can replace two analogue presses and runs at flexo print speeds. It takes 12 colours, zero plates with very quick changeover between jobs and almost any media.

drupa 2024 also underscored the industry’s eagerness to adopt more efficient and sustainable practices. For printers and converters, the expansion of digital technology will be a key priority.

When HP invented thermal inkjet, it took the publishing world by storm. Today, HP said it prints over 244m/min. It also introduced its LEP technology, and its ongoing innovation has turned it into one of the gold standards for digital printing.

Today, the new LEPx is delivering high digital print quality at flexo print speeds – 120m/min – in label production. LEPx is going to expand into commercial printing, flexible packaging, and other new markets.

But HP said that is simply not enough.

It said looking at the entire production and integrating IA into every single stage is the best way forward.

What differentiates HP’s IA is that it is data driven. It takes data straight from the production floor, analyses it with AI, derives insights, then through integration with the relevant system, it either takes or recommends the right action.

It is all done with HP’s cloud platform, PrintOS. Even processes such as predictive maintenance and service routines are all intelligent – and it’s not necessarily just limited to HP presses. With the new Production Beat, analytics can be run on all equipment.

HP has also added the Smart Workcell Controller to its PageWide presses, enabling productivity to be increased by up to 15 times.

The intelligent factory of the future is no longer a distant dream. HP is continuing to push the boundaries today and its vision for the future of IA in printing production is clear.

“Welcome to the next 20 years,” Levit added.

HP Indigo is proudly distributed and serviced in Australia and New Zealand by Currie Group.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter

This blog beautifully highlights the transformative power of intelligent automation in digital printing. It’s inspiring to see how HP is shaping the future of efficiency and innovation in the industry!