Much has been said and written about the world of colour control. Rarely, however, does one hear of Australia’s 17-member Technical Agreement Group (TAG) – – the gentlemen and lady presiding over its administration (the division of the sexes seemingly somewhat skewed with RMIT’s Meredith Chesney a sole female affiliate).

Nevertheless, its achievements over recent months have been impressive, not the least of which, having demonstrated to the Australian Standards Association its competence to represent its industry, was receipt of the green light to prefix the graphic arts’ ISO12647 suite of standards with the coveted AS.

The suite comprises:

ISO 12647-1:2004: Graphic technology – Process control for the production of halftone colour separations, proof and production prints – Parameters and measurement methods;

ISO 12647-2: 2004: Graphic technology – Process control for the production of halftone colour separations, proof and production prints – Part 2: Offset processes;

ISO 12647-3: 2004: Graphic technology – Process control for the production of half-tone colour separations, proofs and production prints – Part 3: Coldset offset lithography on newsprint;

ISO 12647-4: 2005: Graphic technology – Process control for the production of half-tone colour separations, proof and production prints – Part 4: Publication gravure printing;

ISO 12647-5: 2001: Graphic technology – – Process control for the manufacture of half-tone colour separations, proof and production prints -Part 5: Screen printing;

ISO 12647-6: 2006: Graphic technology – Process control for the production of half-tone colour separations, proof and production prints Part 6: Flexographic printing;

ISO 12647-7: Graphic technology – Process control for the production of half-tone colour separations, proof and production prints – Part 7: Proofing processes working directly from digital data.

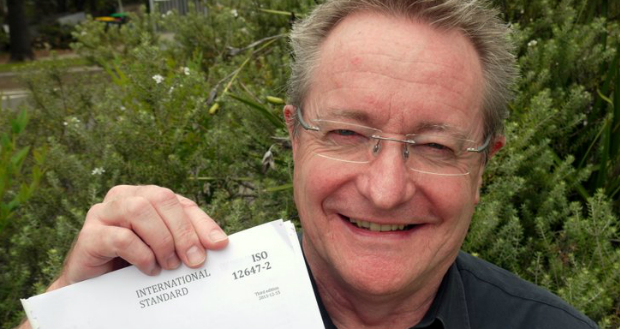

A joint initiative of the LIA PIAA, the TAG is made up of a broad cross-section of industry representatives, academics and consumers (ie buyers). Chaired by LIA executive director, Bob Lamont, its participants include prominent industry identities Bruce Sinnott, David Crowther and Warwick Roden.

Lamont laments that many in the industry do not understand the implications of standards for colour control; hence, the group’s need for a great deal of educational work ahead of it.

“While there is a significant increase in the number of people who are seeing the benefits of moving to ISO, our job has only just begun”, he told ProPrint.

One of his committee’s priorities is setting up a comprehensive website which will aim to facilitate the adoption of ISO standards and provide industry information on their implications and their broad range of benefits.

No more surprises

While this will go a long way towards closing the gap in understanding of how the industry can benefit from their adoption, the ISO standards, according to Lamont, will show the impact of their major benefits on the print buyer.

“Customers will drive this whole process because they will want to be able to have materials produced in any plant, anywhere across a number of different processes or printed in a local magazine in exactly same way as in 27 others. They know there will be no more surprises.”

Committee member and prominent colour specialist, David Crowther, pointed out that application of the seven ISO standards for the graphic arts industry will enable a print supplier to offer consistency for in-run print appearance, for reprints and job-to-job, plant to plant or even global uniformity.

“It will also mean reduction in ink usage and faster makeready,” he explained, adding, “The standards will enable a printer to aim for a particular colour appearance in terms of LAV values with a three-dimensional description of colour, together with their Delta-E tolerances.”

The standards, Crowther outlined, have a series of aim points indicating solid ink colour for CMYK and three overprints, red, yellow and blue, as well as dot gain. These aim points, together with their tolerances, are achievable on sheet and web fed presses regardless of manufacture. (While not specifically indicated, it would seem that a digital press is no different in this context to a sheet or web press).

The proof of the pudding

The newest of the ISO Standards, dash 7, which refers to working directly from digital data, has been isolated from the others in the 12647 suite, since visually to match a particular printing condition requires a set of parameters that are not necessarily identical to those put forward in other parts of the 12647 suite. This, the ISO Overview cites as being caused by differences in colourant spectra such as gloss, light scatter and transparency. Here spectrocolourimetry takes precedence over densitometry.

These and many of the issues of the ISO standards will be the subjects of constant scrutiny, and updates where required. An international meeting last year, when documenting the -7 digital proofing component, stated, “This document establishes the proofing requirements for the most stringent part of the printing and publishing market. ISO 12647-8, which will follow shortly, will provide a set of proofing tolerances with broader applicability in both the printing and publishing market and the office market.”

As the GAP’s efforts begin to bear fruit, evidence will more and more emerge of the necessary culture change in printing companies. It remains to be seen just how much fruit the efforts of the Group will bear in its campaign to create awareness of the need for more responsibility within the industry to operate within internationally recognised standards. More than an internal challenge to elevate the Australian printing industry to modern levels, adherence to, and working within, the graphic arts ISO Standards will represent yet another step to international competitiveness.

The efforts of the public service-minded participants of the Group have given the industry a dramatic start. It remains to be seen to what extent the average print supplier is prepared to undertake consistent monitoring programmes to measure progress toward improving standards.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter