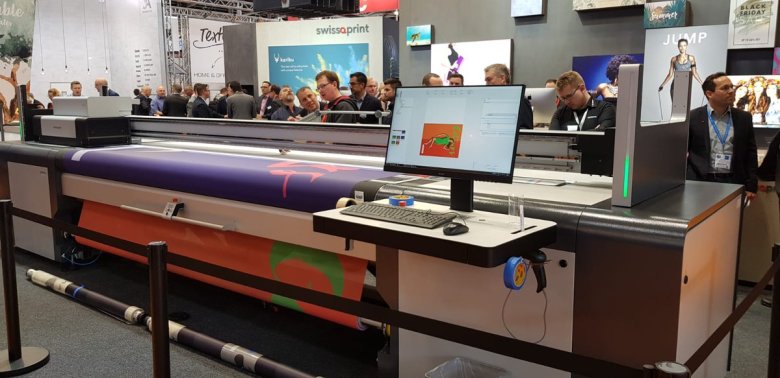

Karibu, the first swissQprint roll to roll printer, made its public debut yesterday at Fespa.

The 3.4m UV inkjet printer is designed for low running costs, reliability, and ease of use, including a cassette system, where rolls are loaded and ready to print within minutes.

The system will be sold by Pozitive in Australia, with managing director Phil Trumble explaining, “The Karibu from swissQprint represents to epitome of quality, versatility and reliability in one package, dedicated to the roll to roll market. swissQprint’s DNA is found in every corner of Karibu and we are excited to be able to bring its features to Australian market.”

Petra Fetting, marketing services and communication, swissQPrint, told Australian Printer at the show, “Our customers have been asking us for a dedicated roll to roll printer. We have flatbeds with that option, but they wanted a dedicated machine.

“Soft signage is a growing market, and we see a big potential there. With the Karibu we wanted to complement our flatbed range.”

For PSPs printing backlit fabrics, the Karibu features a light box right next to the printing area, for immediate and continuous quality control of prints as they will appear in their environment.

As a result, the company says neither much material nor time has been lost should optimisations prove necessary.

For those printing on mesh, the Karibu has solved the issue of waste and mess, with an integrated Mesh Kit on the print bed.

This makes clean and simple work of processing permeable substrates, as well as full bleed printing. There is neither additional set-up work beforehand nor cleaning afterwards. A mouse click by the operator sends the Karibu print beam – which is movable in the X direction – from its standard position to the mesh position. Printing can then start immediately.

With multiroll capability, the Karibu can handle two rolls up to 1.6m wide, doubling productivity. The roll holders are split into two sections with each half of the shaft driven individually, which swissQprint says results in optimum web tension and perfect results on both rolls.

Karibu has 136 keys ranged across the print bed width, rather like a piano. Each one opens or closes a vacuum channel, thus eliminating air leakage even in the gap between dual rolls. A light tap on the switches using a fingertip is all the user action required to open or close the entire vacuum area width within four seconds. This is called Tip Switch vacuum, a technical solution for which swissQprint has filed a patent application.

Karibu has four beacon-like status indicators affixed to the print beam. They are observable at a distance and inform the operator about machine status and printing progress. So it is always possible to keep an eye on Karibu, even while the operator is elsewhere in the print room taking care of other equipment or tasks.

The company has developed an ink set specifically for its new Karibu roll to roll printer, where the cured ink layer is flexible to ensure suitability for all imaginable roll media. The inks themselves are NVC-free and Greenguard Gold certified. Printed products are thus safe to use in critical places such as hospitals and schools, potentially broadening a print provider's range of services.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter