Komori and Screen GP have finished development of a new integrated workflow solution, which the first user claims will lead to the creation of smart printing factory with total integration, robotics, artificial intelligence.

The Komori Screen solution combines KP-Connect Pro (formerly K-Station 4), Komori’s advanced printing task control software and Equios 5.0, the latest version of Screen GP’s universal workflow platform. The companies say it enhances automaton in all processes from prepress to printing and through to post press.

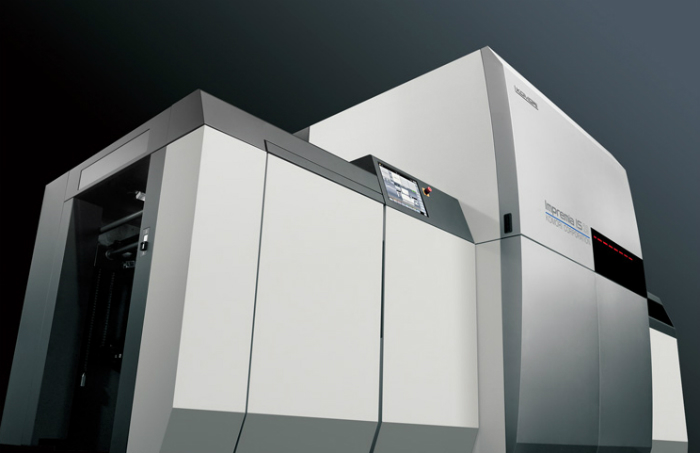

The workflow is already installed at Japanese printing company Mizukami Insatsu, where it is currently performing verification tests. It has been installed to improve automation along a hybrid printing process including a PlateRite plate recorder, Lithrone G sheet-fed offset press and an Impremia IS29 29-inch sheet-fed UV inkjet digital printing system.

These systems will also be linked to postpress devices via JDF, creating a workflow that supports comprehensive integrated control from prepress right through to postpress.

[Related: Komori reveals drupa plans]

Katsuya Kawai, president, Mizukami Insatsu says one of the prime goals it is promoting is the creation of a design for a smart factory by 2025.

“All devices, peripherals and processes will be connected using the internet of things concepts, enabling dramatically improved transparency of real-time operations. A single operator will control multiple systems, part-time employees, AI and robotics. Our vision is to create a smart factory that uses next-generation printing logistics to achieve a truly new dimension of productivity,” he says.

Eiji Kajita, director and operating officer, general manager corporate planning office at Komori says “I firmly believe the next-generation workflow solution formed by Equios and KP-Connect Pro will help to significantly improve the optimisation and perofmrance of prepress, and in fact the entire printing process.”

“We are currently performing verification tests of this workflow at Mizukami Insatsu, a highly progressive company that operates print lines including combined offset and digital systems. It fills me with pride to be able to make this announcement,” he adds.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter