Tell us about your business

CMYKhub is a trade-dedicated digital, offset and ganged print supplier operating manufacturing facilities in Melbourne, Sydney, Brisbane and Perth. As a trade-only supplier, we see our role as adding equipment and technology that allows printers to remain competitive without having to invest in expensive capital equipment. We work with our customers to grow our businesses together.

What have you bought?

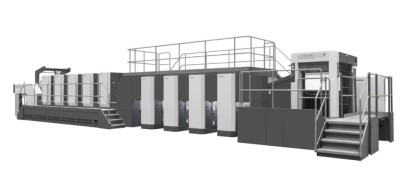

Last September we signed a contract with Ferrostaal Australia to supply a Komori G40P eight-colour perfecting press with H-UV drying. It’s the first installation of this technology within Australia.

What does the new press do and why did you choose it?

We chose the press for many reasons but the highlight features were low energy, instant drying, perfecting and 20-sheet makeready. Due to the massive number of makereadies we do, this press is exception-ally fast at job changeovers, which caught our attention at Drupa 2012. Also, being a perfecting press, it makes us much more competitive on longer runs.

Many of our customers are small to medium-sized print shops, and having access to this sort of equipment allows them to offer a larger range of products to existing customers.

We chose the Komori over other presses due to the high speed of job changeover and extremely low makeready sheets. The instant drying from the UV is also vital in today’s marketplace.

What features do you like most?

Other than those already stated, the feature we like most is the closed-circuit colour adjustment on the fly and the quality camera, which photographs every single sheet, compiling a list of defects while tagging the exact sheets with issues. The tagged sheets can be assessed and removed at the jogging stage.

Is there anything you wish it had that it doesn’t?

The one and only feature missing from the Komori is inline registration adjust-ment while running. However, once in alignment, we have found registration easy to maintain so this feature is not critical. Komori has a scanner that adjusts registration each side and back to front when you pull the 20th sheet prior to running on, which works very well.

How fast is it?

The machine will run at 15,000sph maximum. We tested all stocks, including 420gsm board perfected at 12,000 sheets per hour, and were very happy. For short runs high speed is academic – makeready time is king.

How reliable is it?

I audited many Komori users in Australia and the consensus was exceptional reliability. We have found Japanese machines to be ultra-reliable in the past, very frugal on consumables and power, and cheaper to maintain. I was told: ‘A Komori perfector is like an Airbus 380; service it properly and it will never fall out of the sky’.

Has it won you any new business?

We have starting working through reducing costs based on the new press, which has already assisted our customers to win new work. We have a great relationship with our reseller network, and we are all excited about how we can use this technology to grow together.

Were there any difficulties surrounding the install?

The install has been complex. We needed to do a power upgrade, put in a slab that weighs 120 tonnes while running the machine right next to it, raised the ceiling to fit the machine, the high-speed roller doors, the internal insulated walls and the light tube sleeves to remove UV from light sources. We also added air-conditioning and humidifiers to keep the temperature of the press and stock consistent at 25 degrees to help maximise productivity. The install of the machine is the easy bit.

Who is this product right for?

This press is very focused on high-volume, short-run offset while being able to handle longer runs. A press needs to match your work now and in the future. CMYKhub with the new Komori will reinvigorate a lot of smaller printers around Australia to feel confident about the future.

The great thing about the hub model we are building is the relationships with resellers, and how the industry outlook for smaller players has a very bright future.

Supplier’s response

The eight-colour Lithrone G40P provides CMYKhub with a more productive and economical print manufacturing process. The machine will produce makereadies within 20 sheets, significantly reducing waste. CMYKhub has the first machine in Australia configured with the new H-UV technology. This means much quicker turnaround times, minimal drying time and perfect quality. This is the first of five machines we expect to install this year.

Rayne Simpson, general manager, Print & Finishing, Ferrostaal Australia

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter