Tell us about your business

Dominion was established by my father, John Gage, more than 60 years ago. From humble beginnings in the bedroom with a foot-operated platen, Dominion has grown to full service print, design and media supplier. I joined the business 18 years ago and am now managing director. Today we employee 45 staff and service a corporate client base around the country.

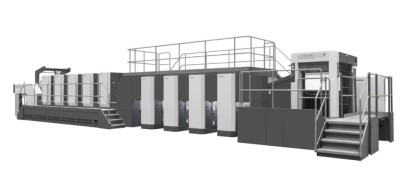

What have you bought?

We have purchased a Komori Lithrone S529. We traded in a Komori L528.

What does the new press do?

You put white paper in one end and it comes out pretty and colourful at the other end. It’s like magic!

Why did you choose this product?

We were already a Komori shop. This press provided us the best value for money and made for easy install and training.

Did you consider any other products?

If you think selling printing is competitive, imagine selling printing machinery. We talked in detail to three major manufacturers and the negotiations were often intense. We even travelled to Hudson, near Boston in the US, to look at the very impressive Presstek. At the end of the day, the Komori was the press we knew. But in terms of the deal itself, the Komori supplier, Ferrostaal, provided much more than just a new press, and this won us over. It was a great example of a supplier examining what our real needs were and coming up with a solution to meet them.

What features do you like most?

From a management point of view, it is simply the efficiency of the press. For the operators, it is the ease of use, speed to get a job ready and the ability to adjust on the fly. Technology can be a great asset.

Is there anything you wish it had that it doesn’t?

We can’t seem to get Foxtel working on the console monitor and it would be great to have on iPod jack to play music instead of the old chimes you get when changing blankets. Seriously though, if money were no object, we would love a 10-colour perfector. But all in all, we are very happy with what we got for the money we paid.

How fast is it?

Today it ran at more than 15,000 impressions all day. That was a combination of all the right conditions. Typically it is 13,000-plus an hour.

How reliable is it?

It hasn’t missed a beat in its first three months.

How easy is it to use?

As with all new technology, there is a learning curve. Our operators are fantastic and have enjoyed the process of learning about their new baby. All in all, it has been a painless process and every day, the operators pick up little new improvements.

Has it won you any new business?

No – that’s the job of our reps. The new machine simply helps us be more efficient. That being said, customers and staff like to see you confident enough in the future to invest in new kit.

Has it saved time and money?

With faster run speeds and more efficient makereadies, we are averaging three extra jobs per shift.

Were there any difficulties surrounding the install?

You always want it to go faster than it does, but the installers were great and worked hard to get us up and running as soon as possible.

How has the pre- and after-sales service been?

Great. David Gunn – and previously Gerard Wintle – were a big help in the sales process. We were fortunate enough to sign a contract with president Komori in Tokyo. Since then, Ian White and his team on the install and service side have been fantastic.

Would you buy another one?

Sure, but with a constantly changing market I would be committed to reevaluating all technologies.

Who do you think this product is right for?

Anyone who still believes in the future of commercial print. We certainly do.

Supplier’s response

Dominion is one of our major customers in Sydney. Dominion has been using two Komori presses for more than 10 years and they have decided to take advantage of the new technology. The Komori LS529 offers immediate savings in production costs with faster makereadies and auto-plate changing. In addition, the new 20 Matching colour-matching concept enables Dominion to create make-readies within 20 sheets, resulting in lower waste and environmental savings.

Markus Haefeli, CEO, Ferrostaal Australia

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter