Komori’s Tsukuba plant has undergone constant upgrades and expansion since its opening just a few years ago. With state of the art manufacturing facilities, the site now has training and education facilities to match, after its opening in October.

Komori president Yoshiharu Komori says: “We have established the Komori Graphic Technology Center (KGC). It will take a major role as a comprehensive training centre and also in collaboration projects with domestic and overseas printing material manufacturers, schools, universities and the worldwide printing industry.

“KGC will also provide demonstrations and fulfil training requirements of our customers from the basic fundamentals of printing and the printing press, to high-level technical training,” he added.

The company co-operated with close to 30 different partners in the industry, among them Dainippon Screen, Horizon, Kodak, Konica Minolta and Epson, to establish the KGC, which will also be used by the Printing College and will educate and train graphic professionals to achieve higher skills levels in their profession.

Based in Tskukuba, Japan, the KGC found its home among the 64,000sqm floor space at Komori’s factory area that also houses sheetfed and web press production, the latter having moved earlier this year to this location.

The new KGC caters to different languages, with courses to be given for starters in Japanese, English, Korean, Chinese, French and Spanish. The company already has registered a high demand for Korean courses.

Komori’s management principle of “Kando – Beyond Expectations” will guide the participants, says the company. “Komori will achieve the best manufacturing quality in the world, deliver ‘Kando’ in printing technology and firmly establish the Komori brand identity all over the world,” said Mr Komori.

Inside the centre

There are four main functions for the new centre, which doesn’t necessarily cater only to Komori customers, but to professionals from all over the world. “In the demonstration centre we want to demonstrate our printing quality and promote our presses to worldwide customers,” said Komori’s Hiroyuki Sugiyama.

Educational courses in printing technology are given in the college and DoNet area. There is also the technical training centre that lets Komori train service and production staff from all over the world. Primary research of printing technology takes place in the new Printing R&D Centre.

“We are very proud that our customers recognise the high quality our presses are outputting,” said Mr Sugiyama. “However, this can only be achieved by a high standard of co-operation between printers, suppliers and manufacturers, and we appreciate the feedback given to us, so this facility also offers us the possibility of co-operation that allows us to research and advance our presses and printing technology to its fullest, benefiting all participants in the market.

“By developing everything together numerous advantages for all partners, as well as printers, will emerge and drive printing forward.”

Komori plant list

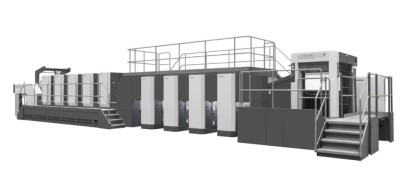

No fewer than 11 printing presses have been installed at KGC. Within the demonstration centre, a Komori Lithrone LS-440SP, an LS-840P, an LS-640c+UV as well as an LS 629C+UV can be seen in action. These cater to different needs of printers such as special printing, high production perfecting, quick job changeover with fast makeready, printing to world-quality standard and environmentally friendly and high-efficiency printing. The printing college and DoNet Area houses an LS-40 and a Spica 429PW as well as DoNetrelated equipment including prepress devices and software.

“Lots of the courses and training is hands-on, meaning that it is taught right next to the products,” explained Mr Sugiyama. Established for teaching printing techniques to customers, regular courses for general offset printing (Beginners for five days, Intermediate for three days and Advanced for five days) are being offered.

In addition, technical training, operation before shipment, control for printing factory and press maintenance, but also practical seminars (introductory colour management, quality management, CIP4/JDF environmentally friendly printing, FM high-technical printing, waterless printing, print troubleshooting among others) are offered.

In co-operation with pre-press suppliers, the DoNet area has also been equipped with state-of-the-art machinery, like the PlateRite 8800Z CtP device from Dainippon Screen together with Trueflow SE workflow and the automatic plate developer LP-1310H (made by Fujifilm).

Within the Printing R&D Centre, a Lithrone LSX-640C+UV has been installed. Here research is carried out in co-operation with domestic and overseas industry, universities and printing material/peripheral equipment manufacturers. The main themes are standardisation, research in printing techniques and materials (paper, ink, varnish, blanket, rollers, plates, dampening, cooling, dryer, powder sprayer etc) as well as technical integration with peripheral equipment.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter