Every small printer has a view on the future of offset printing and Josh De Groot, owner of Longbeach Printing has a very straightforward if somewhat startling opinion: There isn’t one. “It just does not make sense for small and medium printers to be in offset anymore, there is just no money to be made,” he says. “We are in a difficult space right now, almost no one is making any money on offset and I do not see any future for it at all.”

The writing was on the wall for his business, Longbeach Printing, a couple of years ago – despite a healthy balance sheet the margins were evaporating as overcapacity worsened price wars gripped the industry. De Groot was ready to retire and things were getting to the point where it almost wasn’t worth carrying on. “Offset print is now a commodity so it is just a race to the bottom, all you can do is lower your prices,” he says. “Even as a business with no debt the margins were too skinny on offset. This is a crazy industry, I can’t understand why people sell for less than cost.”

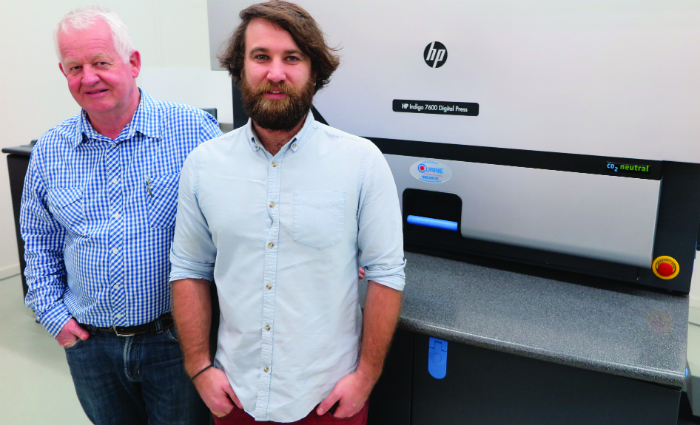

At that point enter his son John, just home from several years travelling, working in pubs and living the dream, having decided that he did indeed want to take over the business. So instead of packing up shop, De Groot decided to radically change the business into something that would earn a living for his family long term. “It was either close the business or change it, so we decided to change,” he says.

A new beginning

Longbeach had always been an offset house, a standard-issue commercial printer running a few presses and outsourcing most of its finishing. De Groot was an army man, serving in the artillery before being transferred to the surveying department. It was there he learned how to print, and it stuck. After a 14-year career he left the army in 1986 and worked at a few different printers before starting Longbeach in 1989. The company began in his home with a two second-hand Multiliths bought from AM Australia, which were followed by a series of Heidelberg GTOs. The first half-sheet offset, a Komori, rolled in by 1992 and was soon joined by a Heidelberg 102. At its zenith in the late 1990s and early 2000s, Longbeach had four presses and 10 years ago had a turnover of $8-9m. Like everyone, the business took a big hit from the global financial crisis and fell to $4-5m a year, though De Groot says this was partly by choice to preserve margins and stop running 24/7 shifts.

The first part of blowing all this up and starting afresh was De Groot buying out a few former business partners to take full ownership of the company. Then came the equipment overhaul. Gone are two ageing offset presses a B1 and B2, and in came digital with an HP Indigo 3550 from Currie and an Agfa Anapurna M2050 flatbed wide fomat last year. The switch to digital continued this year, upgrading the Indigo 3550 to a 7800 and buying at PrintEx the world’s first Anapurna M2540i, plus Australasia’s first Agfa Jeti Mira to be installed this month.

De Groot says that between the 7800 and a Fuji Xerox Color 700 Press, Longbeach has converted 80 per cent of its offset work to digital and is attracting new types of jobs. “We are doing 25-50 jobs a day on the Indigo now, many of which were not viable on offset, and the margin is far better. I can outsource any offset work we get and make more money on it than when we did it ourselves,” he says. “I chose Indigo because you get high-quality prints that are about the same as offset, but can also print on a wider range of paper and synthetic stock, which is a big growth area for us. The registration is also spot on. It is also fitted with a spectrometer so the colour consistency is perfect.”

Investment in wide format is also paying off, with Longbeach to expanding its product range beyond A4-A1 offset printed posters to almost any wide format job, including printing on corflute, timber, and other specialist materials that have high margins and demand consistent quality. “Wide format brings a whole new client base to the business and the margins are far better than offset. It is a growth market and a big part of our future,” De Groot says. Another big investment was setting up a whole A3 bindery department from scratch so it can do all its finishing in-house – adding value to every one of its jobs and keeping all the profit.

The payoff

De Groot admits it was a tough year retooling the entire company from the ground up. Staff had to be retrained, new processes had to be devised and implemented, and sales staff needed to convince clients Longbeach could deliver in its new identity, and then market a huge slate of new products to unfamiliar markets. “It was slow going this past year but now we have a profitable business looking ahead instead of one going nowhere,” he says. “It makes sense for small to medium printers to get out of offset and go full digital, we have invested a lot in new machinery, but we made this big change to secure our future.” A look around the offices and production floor reveals plenty of evidence – experimentation is rife and staff have embraced the ability to print on almost anything from wood to glass, plastic and perspex with a range of inks and adhesives.

De Groot says changing direction has not only given his business better margins, it has cut operating costs in half and is so efficient that he was able to reduce staff numbers from 30 to 16. “An offset press needs at least two people to run it, while we are now running three digital machines with two operators, so already there is a saving there,” he says. Processes are also streamlined, with a fully digital workflow De Groot developed himself in conjunction with Carbon Data Solutions, which is now being used by other printing companies. Job bags are also all digital and many processes are automated.

Turnover has dipped a bit more in the changeover, down to $3-3.5m, but that was to be expected and De Groot thinks it will pick up again now the company is where it wants to be.

“We drove to reduce costs and improve our bottom line so we went from about $300,000-$350,000 a month to $200,000-$250,000 but much more profitable, and I think we can quickly improve to $400,000 a month from here,” he says. “We are selling on value now and the clients we lose on price usually come back. Reliability, quality and service make price insignificant and people remember that long after they forget what the price of a job was.”

Passing the torch

The next big machinery investment is not far away either, with plans to install some kind of B2 digital printer next year, be it an Indigo 10000 or the newest technology presented at drupa come May, to ramp up speed and capacity as the company looks to return to its former capacity sooner rather than later. De Groot hopes everything beyond that will be the responsibility of his son – now that John is back, De Groot is grooming him to take over so he can get on with retirement. While John gained some business experience managing pubs, his printing experience was minimal. Now he can operate every machine on the floor and is helping to make major decisions. “I am looking to gradually hand over to him in the next 12 to 18 months as he develops his skills,” Josh says. “So he will spend more time running the business and I will spend more time fishing.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter