This excerpt featuring the Massivit 3D range printers was included in a recent 3D Technology Focus published in the June 2021 issue of ProPrint magazine.

3D printing is no longer new or experimental. It has permeated all corners of the community, including our classrooms. But what does it mean for Australia’s commercial print houses?

Nailing a corner of the modelling or prototyping market is a coup for those struggling with diminishing opportunities. 3D winners will be companies already established in the visual display space, perhaps with strong connections on the exhibition circuit.

Artcom Fabrication

Printing 3D collateral is a significant element of the services provided by Western Australia’s Artcom Fabrication, which specialises in signage, wide-format, etching and engraving, acrylic and metal fabrication, and cutting services in waterjet, CNC-router and laser cutting.

Artcom Fabrication installed a Massivit 1800 in 2019 and managing director, Mark Walkden, described it as a “brilliant” machine which has helped open his business up to a broader range of sectors. The most notable relates to the prototyping of parts for the oil and gas industries, dashboard making for boat builders and public art displays for art galleries.

“We just did a project for a major gas company which did allow them to save hundreds of thousands, or even millions, of dollars as it meant they could keep the rig open,” Walkden told ProPrint.

“We were able to print the prototype part for them on the Massivit 1800, they were able to fly it to where it needed to go and test it and then go back to the workshop and build it out of steel.”

Public art works are also another major application area for the Massivit 1800 with the machine recently used to print a number of pieces for an upcoming exhibition at the Art Gallery of Western Australia.

“The machine, its concept and the ability it has to print things fast and large is pretty impressive,” Walkden said.

“We have done a few point of sale items for advertising clients as well, so it is an all-round machine for different industries once customers have the mindset of looking at something different.”

Coleman Group

Rod Peter, managing director of Coleman Group, an eight-decades-old printing enterprise in Sydney’s Strathfield South, sees his own career arc as a parallel to the success of this venerable signage company.

“I started off as a signwriting apprentice, and now I’m selling an Australian product to some 200 dealers across the US from our office in Los Angeles, and we sell it into the UK as well,” Rod said.

The product is REXframe, a globally patented extrusion brand of lightweight aluminium components for temporary displays, which the company initially imported, then began manufacturing locally from 2012. It now has gained its own division at Coleman, and the customers, aside from those in Australia, include a growing cohort of North American printers of signage and exhibition furniture.

The next step for Rod and group CEO Glenn Coleman was to go 3D, with the purchase of a Massivit 1800 Pro, from Graphic Art Mart at Sydney’s PrintEx19.

3D has been a natural fit with promising results appearing well ahead of the pandemic, then a well-executed investment in PPE. And now, as the pandemic hopefully wanes, the real, long-term business of profitable 3D printing, usually in one-off lots, is emerging.

Large-scale work done on the Massivit 1800 Pro include agricultural applications, such as irrigation products.

“The main reason we got into 3D printing was exhibitions, but over the past 12 months, we’ve found other little avenues,” Rod says.

But he cautions, “The market in Australia will be fairly small.”

The company’s early and ongoing production of large-scale models from the Massivit 1800 Pro has expanded to include smaller items with a higher colour fidelity and finer detail on a Mimaki 3D UJ-553. This diversification led to the company spinning off its Mammoth3d brand.

“Mimaki is more your high-end work – we do museum work. There’s less labour in finishing it but obviously it’s a lot more expensive to print. We use it a lot for prototyping, and it’s moved us into a different area, while the Massivit does the much bigger sized jobs but there’s more finishing in those,” Rod said.

Composite Images

At Composite Images, in Sydney’s Artarmon, 3D printing has slotted in as a dynamic addition to its services in the flatbed and roll-to-roll services space.

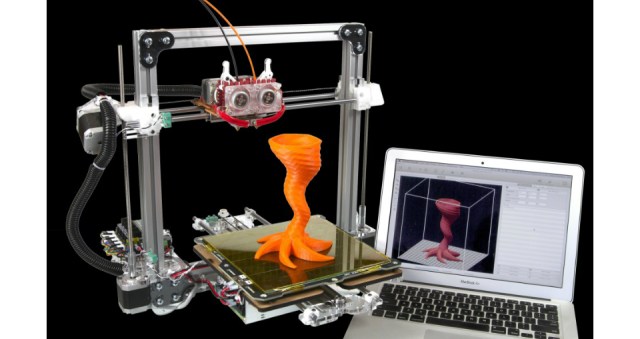

The company’s marketing manager, Samantha Scott says, “We produce our 3D printing on the Massivit 1800 Pro which is a large-format 3D printer capable of printing a single piece that is 1.2m x 1.5m x 1.8m. We use Rhino 3D software to work with our STL files in a prepress capacity, assessing the printing viability of the file and then preparing files for print.

“3D printing is a market that has seen incredible growth over the last few years, COVID aside. With customers’ increasing demand for updated and improved visual merchandising and brands seeking alternative strategies to attract customers to in-person stores and events, I don’t see the growth of 3D printing slowing down soon.

“Initially there was a steep learning curve for us as a business and our customers, in understanding where our 3D printing was best positioned. We have found 3D printing with the Massivit has been most beneficial and applicable in the marketing space – whether this be as props in TV commercials or shows, instore promotions and point of sale advertising, brand activations or events.

“3D printing lends itself to producing bespoke items that would otherwise not be possible within budgets and timeframes, and to the finer detail we are able to achieve.”

ProPrint recently watched a Massivit 3D webinar from the company’s Israeli headquarters.

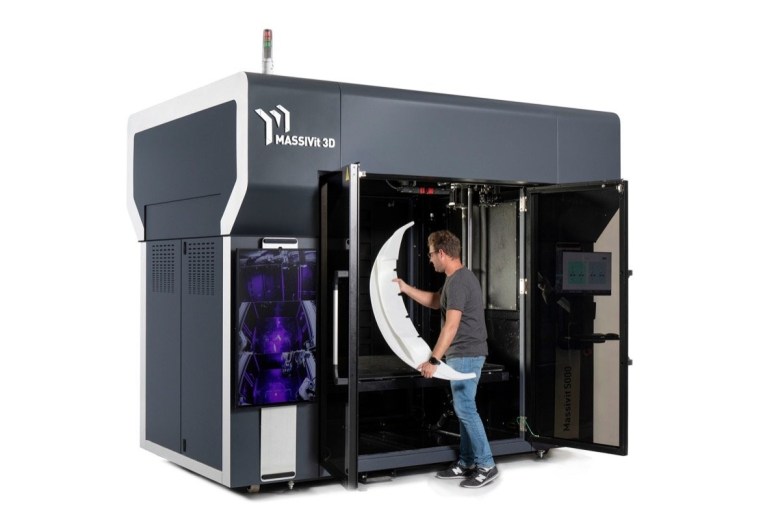

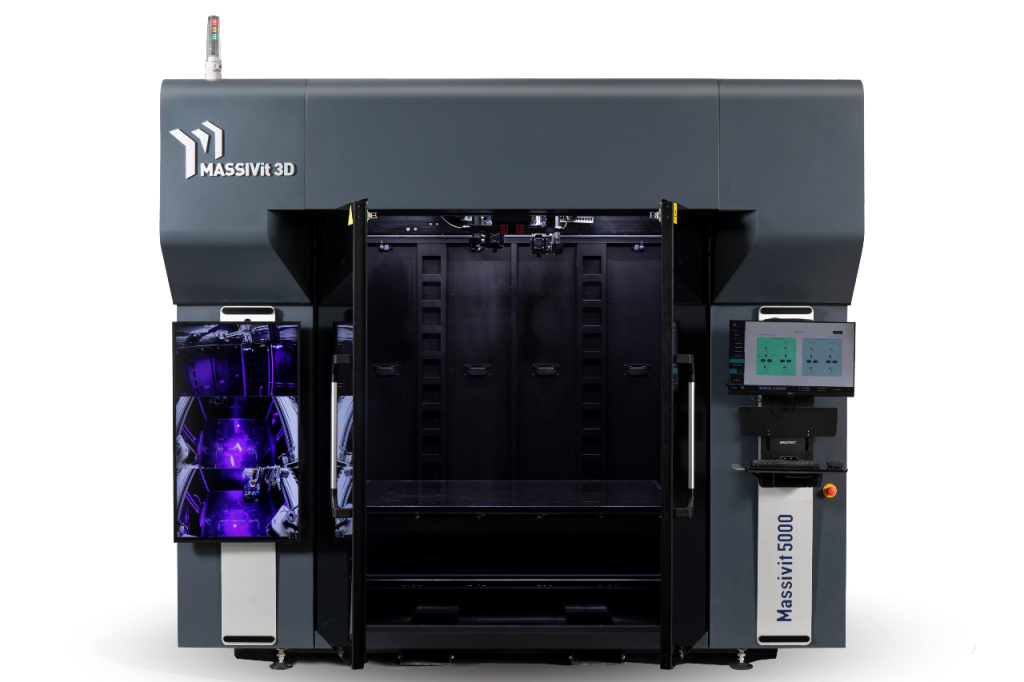

Massivit 3D Product Marketing Manager, Nati Azulay, said the Massivit 3D range, particularly the new large-scale Massivit 5000, offers the growing 3D printing market the opportunity to produce “fast and large parts, prototypes and moulds for applications including scenic fabrication and signage and display”.

Massivit 3D, founded in 2013, has drawn worldwide attention with its ability to handle outsized prototyping projects, such as yachts that actually can be tested in water, vending machines, and projects as complex as 16-component vehicle body parts.

A Massivit 1800 was recently used to produce a full-scale concept car for car designer, Takumi Yamamoto.

With the new Massivit 5000, Azulay says, “the speed issue has now been cracked” and notes it takes only six hours to reproduce a a life-size human figure.

He says Massivit 3D’s genius lies in its GDP (Gel Dispensed Printing) technology which he claims is superior to liquid or powder agents. A photo polymer gel is dispensed by the two independent printheads in layers that are cured by UV light on the fly.

No post-processing (endemic to the printing) is required as the Massivit 3D printers produce ready-to-handle 3D printed objects. Offline painting, filling, sanding and coating are optional, depending on the requirements of a particular prototype. The Massivit 1800 can use media down to 0.8mm thickness, while the new Massivit 5000 can handle resolutions down to 0.5mm.

The Massivit 3D printer range is imported into Australia by Melbourne’s Stick On Signs, whose CEO Abe Weiszberger tells ProPrint that 3D printing – and the Massivit 3D range – have created exciting new opportunities for Australia’s print providers.

Graphic Art Mart handles sales and technical support for the Massivit 3D suite in Australia.

Graphic Art Mart’s WA business manager, Michael Liveris, says the Massivit 3D printers can produce full-scale prototypes, moulds and parts within hours.

“It eradicates the time wasted on producing and joining numerous small parts,” Liveris says.

He says the new Massivit 5000 brings to market a new category in additive manufacturing.

“Offering 30 times the production speed of other technologies, it enables manufacturers and service bureaus in the automotive, marine, and rail industries to produce large, custom parts within a matter of hours instead of weeks,” Liveris says.

He adds the Massivit 1800 Pro offers high performance and resolution, and the flagship 1800 continues to offer supersized, unique models, displays, and props.

Liveris believes print providers need to know their customers and their markets to view the potential of 3D printing.

“We have seen exhibition companies excel in this area, as 3D printing allows concepts to become reality by printing unique, lightweight displays that generally their competitors can’t offer,” he said.

If you enjoyed this excerpt, you may also like to read our story about Artcom Fabrication’s Massivit purchase.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter