What does the product do?

The Mcor Iris is a 3D printer that uses standard office paper to produce models at a fraction of the cost of competitive products. The vendor also promotes the machine’s colour capabilities; after all, it uses paper, “the original and natural medium for coloured ink”.

When was it launched?

The device was first unveiled by Irish manufacturer Mcor Technologies last November. The Iris is set to be launched in Australia by DGS 3D. The local vendor, appointed in May this year, and the team were in Ireland for training with the Iris.

What market is it aimed at?

The device aims to bring 3D printing to the masses. The obvious target market is the AEC sector (architecture, engineering and construction). Universities are also showing strong interest, especially for the design and architecture faculties.

There are also opportunities here for printers, says DGS 3D managing director Connor Moore. He notes that Mcor has a global deal with Staples, which is using the Mcor Iris to establish its ‘Easy 3D’ service, whereby people can upload designs to their website and have full-colour 3D printed models delivered or picked up in-store.

Moore says that “service bureaus”, such as franchise copy shops or chain office supply stores, could be prime prospects, as they already supply clients such as design studios and universities. They could also service end users who can’t afford their own 3D printer – “customers like students who had no opportunity to print before,” says Moore.

How does it work?

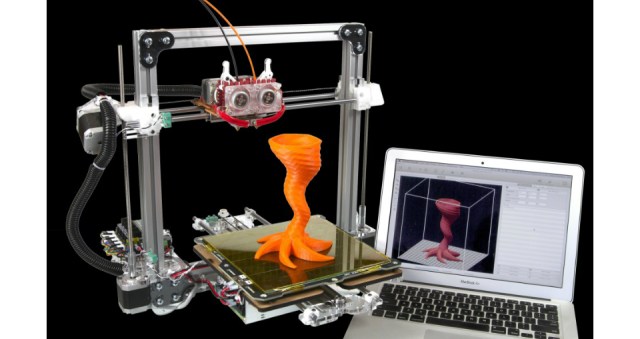

Moore explains that producing colour models is a two-stage process: first sheets are printed on the Epson B510 printer housed in a sliding drawer in the base of the Mcor Iris. These printed sheets are then fed into the Iris, which glues each sheet together and builds up the 3D model layer by layer.

The package comes with two pieces of software. ColorIT is used to enhance the data file, for instance, to add colour, correct the image or improve the resolution. This will only be required for colour models. Every job will require the SliceIT software, which breaks the 3D image down into separations, which can then be printed onto individual sheets. SliceIT also maps out the glue lines that the Iris will lay down.

The system uses proprietary water-based inks designed to saturate the paper. The part of the sheet that corresponds to the outside of the model will be coloured, while the rest of the sheet remains white. So for instance, if producing a model of a tennis ball, each sheet would show a ring, about 4-10mm thick, with the circle getting larger on each successive sheet until it reaches the widest part of the ball, then smaller again. The white area inside of the circle would be the inside of the model, the rest would be offcuts (or, as Moore calls it, “support material”).

The Mcor cuts around the outlines of each coloured segment as it glues sheet to sheet. Multiple 3D models can be also be ganged to make the most of materials.

Could I use my wide-format printer?

Moore says using anything other than the Epson supplied “simply will not work”. “The printer is part of the package and has been modified in the paper tray, and adjusted for the duplexing function. The printer also uses aqueous/solvent-based inks that Mcor have patented to penetrate the paper consistently. This printer has also been selected for its duplexing speed,” says Moore.

How easy is it to use?

Very, says Moore. It is simply a matter of loading blank paper into the Epson printer then transferring this printed output to the Mcor Iris. The Iris scans a barcode printed onto each sheet to get registration data. If one sheet is spoiled, it is easy enough to print a new sheet and slot it into production. Mcor offers full training on the software.

How does it differ from competitive products?

The price point is the biggest standout over rival machines. According to DGS 3D, the cost per model is $0.0041/cm3 for white models and $0.04-0.05 for full-colour ones. This is around 20 times cheaper than rival technologies and one-fifth of the ongoing costs “of any other 3D printing technology,” claims the dealer.

What are the specs?

With A4 paper as the base material, the Iris can produce a 3D model up to 256x169x150mm. Moore says it could produce a single model “roughly the size of a rockmelon” or a number of individual models ganged across the stack.

How much does it cost?

The machine is priced at $54,950, with two days’ training and installation adding another $2,500, bringing a total of $57,450, fully installed, with a one-year warranty. The package includes the Mcor Iris, modified Epson printer, licence for Colour IT and Slice IT, full set of CMYK inks, 50 blades and 12 bottles of adhesive – equivalent to 12 months’ printing.

“Mcor is trying to make it as low cost as possible, basing it on normal copy paper, blades and inks,” says Moore. He adds that because the printer only prints about 3-5mm lines for the surface of the model, jobs don’t use much ink.

What training, service and support is on offer?

DGS 3D offers two-and-a-half days’ training as part of the package. The package comes with a one-year warranty on parts and service, after which tailored agreements can be arranged. Support includes telephone and email back-up as well as remote access.

Have there been many installations?

It is still early days. Moore says that Mcor has signed up about 60 resellers around the world. Local sales are expected after the official launch of the Iris, set to occur in August.

Specifications

Price $57,450

Contact DGS 3D, (02) 9683 6065, info@dgs3d.com.au

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter