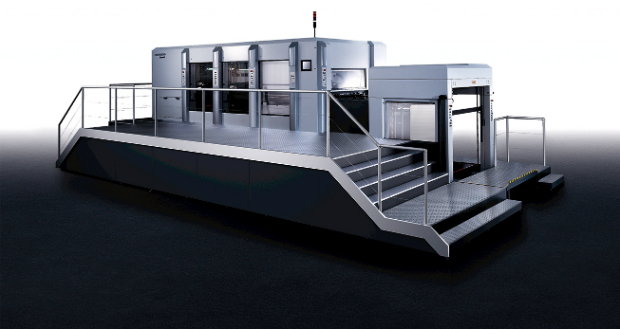

Managing director Lou Mimmo said the arrival of the “state-of-the-art” machine in July would allow the Melbourne company to maintain its reputation for quality.

“This is the reason we’ve chosen the Dymatrix 113 – so we can continue to demonstrate market leadership and meet our own very strict KPIs for quality and productivity,” he said.

“Our internal KPI for full on-time delivery sits at 99.5% and we have very strict internal quality controls also.

“To meet our KPIs we need to give our team all the right tools. When we started to see defects coming through in the cutting area we knew we needed to bring our die-cutting equipment up to speed.”

The Dymatrix cuts, strips and blanks, and it won Mimmo over when he saw it operating at sites in Germany.

“We’ve never had a machine that blanks so output will be greater and it will remove a manual handling process as well,” he said.

“The Dymatrix runs a lot faster than our current machines and the fully automatic logistics system for stack changes on and off the machine allow the machine to run non-stop from the start of the run, even on very long runs.

“Plus its high level of automation will enable us to reduce make ready times considerably giving us greater capacity.”

Mimmo also praised the Dymatrix’s cutting plate, which can be electronically adjusted, and the machine’s gearbox, which allows users to achieve consistent cutting pressure even from a cold start.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter