Manufacturer of the Truepress Jet series of digital presses, Screen, and colour experts CGS Oris, have jointly developed a new technology that aims to save time, lead to better quality printing, and meet the growing need for independent colour management solutions.

The new CxF3 (Colour Exchange Format) spot colour-matching solution – available for the CGS Oris CxF Toolbox – is a response to market demands for software that can guarantee colour consistency and enhance efficiencies for new and existing customers.

Spot colour printing is recognised as one of the best methods to capture and transmit all of the detail in colours, according to Screen.

Unlike conventional ICC profiles, CxF data includes the spectral information of the spot colour, including halftones and transmittance, allowing for more accurate colour calculations and an optimal basis for the precise reproduction of a colour at any time.

However, Screen mentioned that generating CxF data can be a lengthy process, as it requires charts to be printed and measured for all printing conditions as well as target values to be set.

Screen Australia managing director Peter Scott said as printing methods have expanded with the uptake of digital printers and hybrid solutions, this has led to a need for independent colour management solutions that can deliver consistent colour reproduction – even when switching from a conventional printing press to a digital output.

“Screen and CGS Oris have co-operated for a while on various aspects of colour management. This new CxF spot colour initiative is a great boost for the label and packaging industry in particular, as spot colours are often a contentious issue between brand owners and print service providers,” he said.

“Mixing and applying special colours is time-consuming and expensive, now 100 per cent accurate spot colours can be generated for our L350UV SAI label and packaging presses, quickly, easily and without high-level colour management knowledge.”

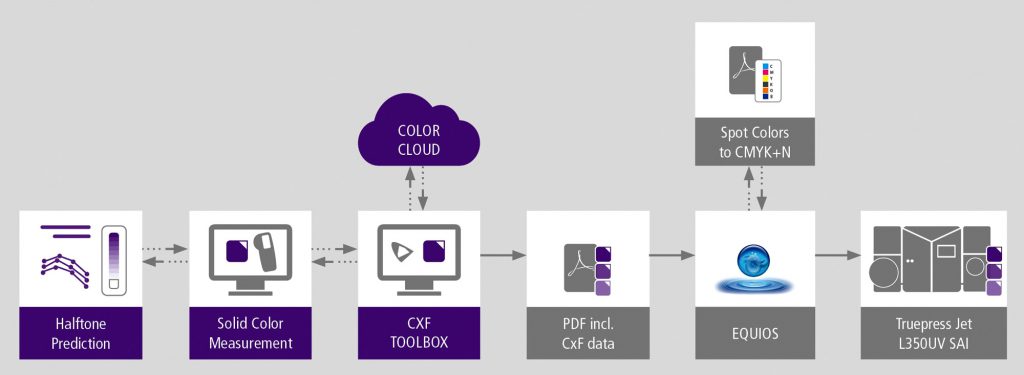

To meet these market demands, the solution predicts halftones from limited colorimetric data by using a proprietary algorithm. This automatically generates complete CxF data, saving significant amounts of time.

The CxF Toolbox seamlessly connects to the CGS Oris Color Cloud, the cloud solution provided by CGS Oris to communicate all stored CxF data to the entire supply chain. Authorised users around the world can access it to get up-to-date colour data at any time.

Additionally, the Color Cloud can be used with the entire CGS Oris Software Suite, like Press Matcher, X Gamutetc, and can be connected to other workflows, including Screen’s Equios, and DFEs that work with CxF data.

Screen’s newly-developed UV inkjet printer for labels, Truepress Jet L350UV SAI, processes PDFs with embedded CxF data, and is able to separate them into up to six colours of CMYK + OB.

Some other benefits of CxF include a more holistic representation of a colour, the best fundamentals for reproducing colours on different printing presses, and flexible and independent colour management, regardless of the operator’s skills.

The new technology is available from Screen, which is distributed in the A/NZ region by Jet Technologies.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter