Discover the future of printing with HP and Currie Group

In the wake of digital transformation, the global commercial printing and publishing sectors are undergoing a significant shift in demand patterns

Here, HP and Currie Group examine some of the emerging trends shaping future market opportunities as well as the innovations set to be on show at Drupa – the world’s leading trade fair for print technologies.

Print automation and digitalisation to accelerate

Companies across all sizes are prioritising the digitisation and standardisation of processes to optimise production efficiency and profitability.

Commercial printing is continuing its digital transformation embracing shorter print runs, print-on-demand, and variable data capabilities.

While 2023 saw meaningful progression in automation across finishing and pre-press workflows, we anticipate an even greater push in 2024. Customers especially want to minimise human touchpoints in production to optimise efficiency, capacity, and cost as volumes rebound.

HP is facilitating the drive towards ‘lights out’ manufacturing capabilities. One such example is the HP Site Flow, a manufacturing execution system that is fully integrated with HP Indigo digital presses, available through PrintOS, HP’s cloud-based platform.

This system enables the automation of print workflows and the processing of volume-driven print jobs in an efficient and timely manner, allowing for unattended operation and scalability to handle varying workloads.

Over the next year, data analysis and AI will increasingly help converters improve productivity. However, digital will complement rather than replace conventional technologies in a hybrid approach for years to come.

“Automation and digitalisation are key drivers of growth and efficiency in the printing industry. By embracing these technologies, companies can streamline their operations, reduce costs, and increase productivity. At the same time, they can offer their customers faster turnaround times, greater flexibility, and more customisation options. It’s an exciting time to be in the printing industry, and I’m looking forward to Drupa to showcase how HP Industrial Printing technologies continue to evolve and shape the future of our industry.”

Craig Walmsley, Country Head, ANZ, HP Industrial Print

Innovations at Drupa will demonstrate the future of Labels & Packaging

At Drupa 2024, HP’s advances will spearhead the future of Labels & Packaging, expected to be driven by automation, finishing, and sustainability initiatives that together promise new possibilities for print service providers and their customers.

Among the HP innovations set to take centre stage at Drupa is the gamechanging HP Indigo V12 platform. The 15-metre press utilises LEPx technology that the company claims will be ‘industryaltering’

– delivering 120 linear metres per minute with 12 HP ElectroInk stations and 1600dpi image resolution.

The LEPx multi-imaging architecture incorporates six imaging engines – each making its own colour separation on the blanket belt simultaneously. The new LEPx writing heads feature thousands of LEDs to

compose an image as an electrostatic field at 1600 dpi.

Also on show will be the new Indigo 200K Digital Press, developed to give digital flexible converters a competitive edge with better productivity, on-demand delivery, no minimum orders, unique designs,

reduced energy consumption, and minimal waste. The new press is based on digital technology for digital flexible packaging and a successful install base of over 300 HP Indigo 25K digital presses, series 4, worldwide.

The new series 5, HP Indigo 200K Digital Press, prints up to 56 m/min increasing the productivity of high-margin, sustainable short runs of digital flexible packaging to be delivered in days. The HP Indigo 200K

Digital Press offers a 30 per cent increase in speed and a 45 per cent boost in productivity compared to the HP Indigo 25K.

The HP Indigo 200K also features HP Indigo’s PrintOS software automation capabilities for batching, ganging, and variable data, as well as faster, accurate colour match and workflow. It adds automation tools for operator efficiency, coupled with sustainable production, circular packaging, and food packaging safety.

Sustainability climbing the agenda

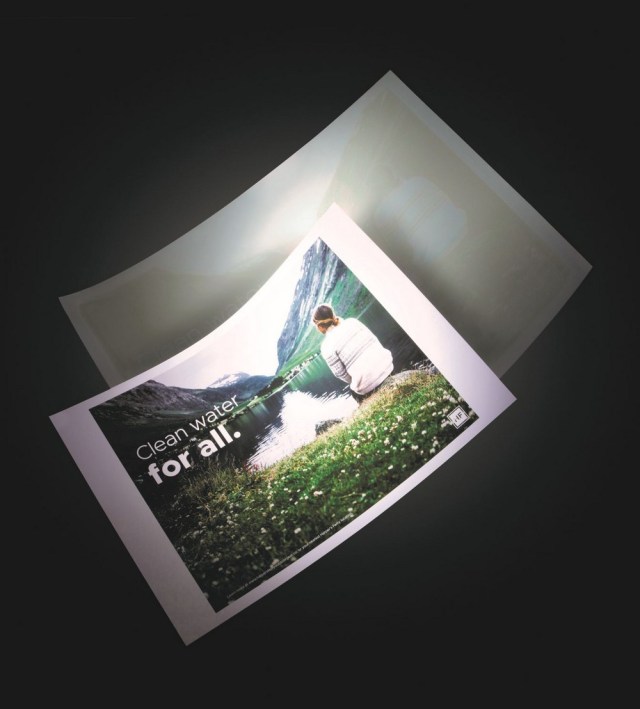

Sustainable printing practices continue to climb the consumer and corporate agendas.

As organisations accelerate their sustainability initiatives, print converters will conduct holistic reviews of business and workflow processes to ensure they deliver end-to-end solutions with minimised environmental impact.

Print service providers are expected to prioritise sustainability across their operations. This includes everything from eco-friendly materials and circular packaging standards to energy-efficient production processes. HP presses align with these sustainability goals, offering reduced waste and energy consumption.

Implementing energy-saving solutions can significantly mitigate the challenges of higher energy costs and material prices. Solar panels, UV LED lamps, automated ink mixing systems, and transitioning from

analog flexographic to digital printing deliver measurable impact.

“With important topics such as sustainable packaging and environmental stewardship being top of mind for us all both personally and professionally, we have seen the industry discourse altered by new and compelling narratives. Sustainability discussions led by global leaders have now filtered down into the everyday discussions we are having with our customers and are high on the agenda when considering technology requirements. The emphasis has shifted to technology that demonstrates reduced power consumption and that uses environmentally friendly consumables and ecologically considerate materials. So, the tables are turning on how to lead the sales process, giving digital printing an even bigger competitive advantage.”

Mark Daws, Director, Labels & Packaging ANZ, Currie Group

Diversification with web-to-print offerings and new business models

Commercial printers are diversifying by expanding offerings for current clients and exploring new business models.

Many are installing web-to-print interfaces to not just enable customers to automate ordering, but also upload designs to produce marketing collateral, promotional items, apparel, and more.

Web-to-print platforms drive increased customisation, speed, and an enhanced customer experience within the commercial printing sector.

In fact, Saal Digital, a global supplier of photo products for customers across the US, UK, and Europe deals with approximately 5000 online orders daily. To meet the growing demand for same-day service, it has implemented HP Indigo 15K and HP Indigo 12000 advanced digital presses, seeking its software automation and overall equipment effectiveness.

As printers adapt to changing dynamics, web-to-print allows them to efficiently handle numerous short and customised print runs on demand.

The new packaging landscape

The new packaging landscape involves managing growth, addressing more complex and more demanding packaging formats, overcoming environmental constraints, optimising brand owners’ supply chain, implementing new regulations, attracting new talent to the industry, developing new business models like web-to-pack, and welcoming new entrants from the commercial printing world.

“Industrial engineering teaches us that plant layout, materials handling, quality control and workflow optimisation using robots and software are key pillars in any manufacturing facility. In our world of print, we are looking to HP Indigo and partners such as Horizon to implement robotics, software and new innovations to address the current and future production issues/bottlenecks. By helping customers maximise value-add activities we can ensure they have a sustainable and profitable business today and tomorrow.”

Anthony Jackson, Sales Manager ANZ, Commercial HP Indigo, Currie Group

The labels and packaging industry has continued to enjoy stable and healthy growth. The global label market is also projected to exhibit gradual growth, with an anticipated 3.10 percent CAGR by 2034, surpassing US $671.6 million.

More labels and packaging converters have experienced growth from onshoring as end customers seek more stability, faster turnarounds, and reduced transport expenses.

The labels and packaging industry continues to outgrow the market, driven by trends such as SKU proliferation and the ability to optimise supply chains with on-demand printing and fast turnaround. Customers enjoyed a robust double-digit growth in flexible packaging, particularly folding cartons

and premium labels.

Label converters are offering clients ondemand label and package production in ultra-short batches. As runs shrink to 50, 100, or less, fast makeready and changeover are mandatory. HP Indigo’s automated workflows allow cost-efficient short runs, empowering commercial printers to penetrate the lucrative

packaging space profitably.

Join HP and Currie Group in Messe Düsseldorf, Hall 17. Meet industry experts and let HP inspire you with its production powerhouse and automation for commercial printing, labels, flexible packaging, folding carton, corrugated packaging, sign, display, and decor industries.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter