Cold transfer has established itself as a key finishing process in the narrow web sector and is used extensively for decorating roll-fed labels. To optimize the usage of cold transfer products, they are often processed on multi-web equipment using transfer units suitable for this application. The DISTORUN® cold transfer module from KURZ represents a breakthrough in material saving. It enables metallized areas that are not transferred and consumed in the first finishing pass to be used in subsequent passes, which brings substantial benefits both environmentally and economically. Thanks to its ability to transfer holographic single images, the DISTORUN® module also makes a lasting impression visually.

Successfully in use worldwide

Print shops these days are expected to offer their customers highly efficient and at the same ecologically sound solutions. The competitive pressure is enormous, and it is necessary to respond to this with a broad range of services and special offers. The DISTORUN® module allows printing businesses to economically and at the same time sustainably finish roll-fed labels using cold transfer. They can also expand their portfolio with holographic single image applications to set themselves apart from the competition and generate orders. These functions explain the market success of the cold transfer module. “The DISTORUN® module from KURZ is an absolute model of success and is being used in a wide variety of print shops around the world. Our customers are delighted and are reporting great savings and lucrative new orders. Some businesses have even ordered more modules“, explains Jochen Wening, Head of Sales and Project Management Business Area Application at KURZ.

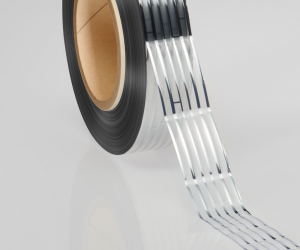

DISTORUN® reduces material usage and positions single images

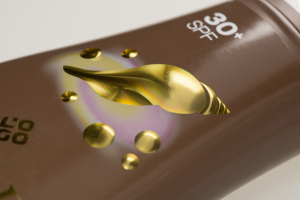

The DISTORUN® cold transfer module uses a sensor to detect areas of metallization on the carrier foil webs that were not transferred during previous passes. The used rolls can simply be mounted, dispensed and stamped several times until an optimum usage of the metallization layer has been achieved. To process single images, the DISTORUN® module scans print marks and controls the transfer of the image onto the substrate with high registration accuracy. This technology makes striking holographic designs available for cold transfer. KURZ has developed two product lines with a special 3D effect that can be used for cold transfer thanks to DISTORUN®: TRUSTSEAL® Lens and TRUSTSEAL® SFX. While TRUSTSEAL® Lens invokes a fascinating spatial depth, TRUSTSEAL® SFX designs appear to protrude out of the surface. These stunning 3D effects turn labels into real eye-catchers and add value to the brand. The elements are also very difficult to copy. KURZ’s customers are not only using the DISTORUN® module for cold transfer decoration but also for security applications, for example on labels.

Fine tuning of the handling

The well-engineered controller of the DISTORUN® module has not required any improvements since it launched in the market four years ago. The engineers at KURZ have used customer feedback to fine tune the handling. The roll winding shafts have been optimized to enable the rolls to be tensioned on the winding axes more simply and reproducibly. A marking of the exact roll position on the winding axis by means of an LED beam has been installed to make roll changeovers easier. Furthermore, there is now a built-in diameter sensor to signal the need for a roll changeover. A rewinding function has also been integrated into the module, which allows, if required, adjustment of the image direction for further processing. These optimizations make cold transfer using DISTORUN® even more efficient.

In addition to cold transfer products and the DISTORUN® module, Kurz offers its customers comprehensive advice in the layout phase to help them find a suitable label layout for achieving optimal finishing results and the most efficient material usage.

Company Contact Details: LEONHARD KURZ (AUST.) PTY. LTD.

Email: salesaust@kurz.com.au

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter