Describe your business

We’re a trade-only large-format printing business. We produce a huge range of products. We print direct onto any surface up to 50mm thick. We can do banners, fencing mesh, corflutes self-adhesive vinyl, carpet for expos, polypropylene for business cards, floor graphics, printing on doors, one-way vision for windows and reusable static-cling stickers.

How many staff do you have?

Four.

What have you bought?

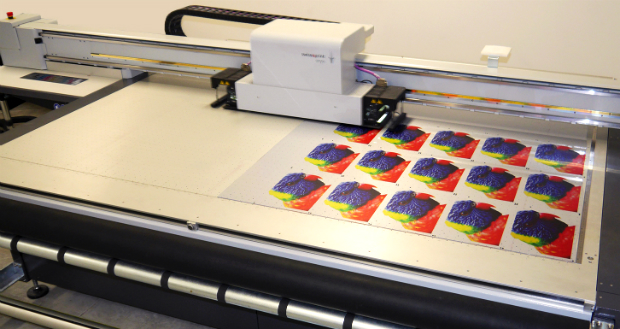

A SwissQprint Impala flatbed UV printer.

When was it installed?

March.

What does it do?

It’s amazing what this machine can print on. It’s a UV flatbed printing machine that has roll-to-roll capabilities and can take a flatbed sheet up to 2.5x4m, which is pretty big. The quality on this machine is exceptional. It can do a spot UV varnish, matte varnish and a gloss varnish.

Why did you choose this product?

Quality was the main reason and versatility the second reason. I couldn’t find anything else offering that combination.

Did you consider any other products?

We had a good look at the Océ and a few others.

What features do you like most?

The quality and the versatility. The cost per square metre is very good too. When you do eco-solvent, you’re paying about $4.50 per square metre, but ours is below a third of that. If you’re doing 1,000m2 per month, you can be looking at a saving of $3,000 per month.

How fast is it?

The full speed is 130m2 per hour, but we don’t run it at that. At high-quality production speed, it’s about 42m2 per hour. Being trade only, we want to run it at a quality speed.

How reliable is it?

It hasn’t missed a beat.

How easy is it to use?

It’s been easy to use. These flatbed roll-to-roll machines aren’t that difficult to use. It’s not as hard as learning to run an offset machine. If you understand files, the chances are you can print on one of these with a few days training. The key is identifying the different substrates and how to handle them. The biggest struggle has been to find the right operator. We were lucky enough to pick up a young guy, Terry Austin, who’s working out really well.

Is there anything you wish it had that it doesn’t?

No, I really can’t find a shortfall in the machine. Swiss, compared with other suppliers, undersell what their machines can do. They’re very conservative. They talk down the machine rather than talk it up. I think the machine actually exceeds the expectations. That’s unusual, and I know, because I’ve been buying printing equipment for 20 years.

How has the pre- and after-sales service been?

The pre-sales service was very good. [Positive Camtec sales and marketing manager] Adriano Gut has been exceptionally helpful. He still wants to talk to you after the sale. We met him demonstrating the product at Visual Impact on the Gold Coast in 2012. It would be nice if Positive Camtec had technicians in the state. But I’ve had better service from Positive Camtec coming out from Sydney than I’ve had from local technicians for other machines I’ve had.

What value for money does it offer?

The cost has been built into the budget. We know it’s going to take 12 months before it starts to return a profit. We’re on target with our first two months’ trade.

How does this machine help you win new business?

The quality is what gets people. Everyone who picks up a job is so impressed.

Were there any difficulties surrounding the install?

No, not really. They got it in there and laid it out. It only took two or three days.

Who do you think this product is right for?

You need someone with a volume of turnover. I think a medium-to-large digital printer or an offset printer wanting to diversify into the market who’s got plenty of room, because the machine has a big footprint and the sheets have a big footprint.

Would you buy another one?

We did have discussions about putting a second one in. If we get to 12 hours a day on the machine, we’ll have the second one on order.

Supplier’s response

The key features are its speed, high quality, versatility and modularity. It can hit 130m2 per hour, which is double anything in its class. Whatever you print looks high quality because of the accurate dot placement. Rod’s machine has an over-sized board option that allows him to automatically index large sheets. He can also finish his prints with an effect varnish or a protective varnish layer. Rod is an experienced printer who clearly knew what he wanted and found it in the SwissQprint. It’s a great machine and can make printers a lot of money due to low ink costs, low maintenance costs, very high reliability and high efficiency. They can throughput a lot more per shift than any other comparable machine.

Adriano Gut, sales & marketing manager, Positive Camtec

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter