Visitors to international trade print trade show Igas in July will see many of the industry’s leading equipment manufacturers focus on the smart factory, which will enable print production to be achieved with few staff, with the aim being virtually none.

Driven by the potential of the cloud, the need to maximise efficiencies, and a declining workforce, companies including Komori, Horizon, RMGT (Ryobi), FujiFilm and Screen all promoted the smart factory concept to the international trade media at the recent Igas press preview event in Tokyo.

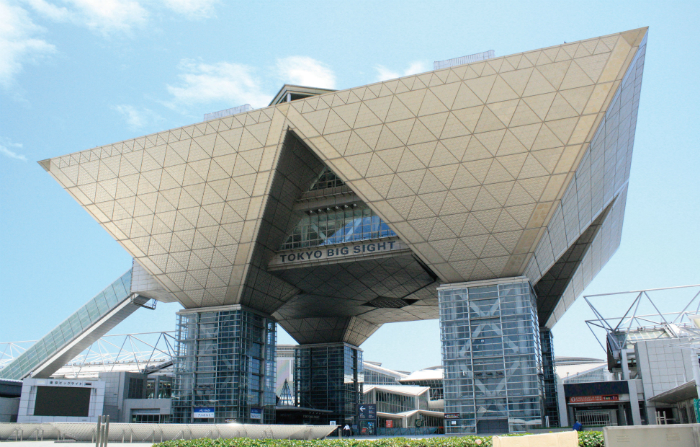

The show, the biggest in the world this year and coming midway between drupas will have a dedicated Smart Factory Zone which will see industry vendors collaborate on the possibilities.

The smart factory concept is the precursor to dark print production, where there are no workers at all in the print plant. In a sign that smart printing is not just at concept stage this month two major Aussie printers have installed robots into their production halls; Southern Colour which now has virtually operator free platemaking, and Active Display Group which is using robots to feed and take off media for its two new giant Onset wide format printers.

At Igas Komori will show a no-touch non-stop offset press that its spokesman at the media event says will have complete make ready in just two minutes, and which will be printing three complete jobs in less than ten minutes. It uses a parallel concept, where plate change, inking and blanket change take place simultaneously.

Komori says its stats show that presses are only actually printing for 33 per cent of the time, a figure it wants to boost massively, through K Connect. It says that it wants to use digitalisation to optimise efficiencies.

K Connect will also link Komori directly with the printer though the cloud. It will provide real time information.

The new digital inkjet B2 sheetfed printer Impremia S29 will be shown along with a digital cut and crease system from Highcon. Komori will also show its G37 A1 press which will be an eight colour convertible perfector for folding carton printing.

RMGT (formerly Ryobi and Mitsubishi) gave an indication of the drive to create smart factories when it highlighted that the current total of 77 million working age Japanese will reduce to 50 million in just 30 years time. The company says this and the belief that people will want to move out of manual work will lead to the smart factory, which is enabled thanks to the IoT, internet of things, and the cloud.

At Igas RMGT will have Assisting your Potential as its theme, as it seeks to enable print business owners to optimise its production equipment though connectivity and digitisation. At the show the company will have its B1 packaging press RMGT 1050 LX-CC+LED UV, which comes with parallel make ready and automated closed loop colour quality control and a new retractable coating unit, and the PQS-D quality control unit. It will also show its 920 Series A1 LED-UV commercial press, which will be in eight unit perfector format. Ryobi says LED-UV uses 93 per cent less power than standard UV. The press will also have a double delivery system, with one delivery for any reject sheets, which RMGT says means that the press can run non-stop, good on long run jobs.

Finishing systems supplier Horizon, supplied in Australia by Currie Group, is also looking at the smart factory, and will show what it says is its intelligent end to end workflow system. Its 1650sqm booth will be its largest ever exhibition space, surpassing that of its drupa stand, with the company also running seminars in the smart factory zone.

Among the solutions on the Horizon booth will be a smart binding system, which will show production flow from printed reel to finished product, and features an intelligent workflow system, which includes automated set-up, variable production, tracking, recovery and integration to upstream.

The printed reel is unwound, cut, folded, book blocked, perfect bound and three knife trimmed, all in one stream, with various auto reject points.

Horizon will have six different zones on its own stand; a presentation area, binding, folding, stitching, cutting and print to finish. The StitchLiner6000 Digital will show both sheet and roll fed solutions. The print-to-finish zone will feature the Horizon SmartStacker inline with an HP Indigo 12000, with an inline print-to-cut and stack process demonstrated.New solutions also include the Stitchliner Mark III and the BQ480 perfect binder, and the company will have its PX net post-press automation on display.

Fujifilm will also be focusing on the smart factory, which it says automates and streamlines solutions for all printing processes, from receiving jobs to production, printing and post-processing. Its spokesman says it does foresee the day of the dark factory. The smart factory will handle all jobs buy optimising production processes and schedules, it will use ICT (information communication technology) and the Internet of Things (IoT) to build a production system that facilitates mass customisation.

The company will also have a major focus on its plans to be fully sustainable by 2030. Fujifilm has a trio of activities in the graphic arts field, including plates, the digital inkjet presses, and in packaging and flexo

The Fujifilm digital inkjet presses will be centre stage, with the company promising an extensive line-up, and a JetPress 720S ink for food packaging, as well as a roll fed UV inkjet press for soft packaging, the JetPress 540WV. The company will also have new items for its workflow XMF Series, and will show a Fuyjifilm and Fuji Xerox integrated workflow system.

HP highlighted its credentials in innovation and the mega trends it says printers should be looking to capitalise on through digital printing, including rapid urbanisation, accelerated innovation, changing demographics and hyper globalisation.

HP says print is perfectly positioned to enable brands to meet their challenges of customer engagement, increasing spend, speed to market and security. The company split in two in 2015, with the graphic division now in HP Inc. HP says it is focused on enabling print businesses to meet the challenges of brand owners, which it identifies as engaging customers, increasing the spend of their customers, improving speed to market.

The company says it is aiming to help print businesses reinvent their operations, highlighting its Print OS business operations app based solution. At the show it will have a full suite of HP Indigo solutions on display.

Screen too highlighted the increasing shortage of skilled operators, the demand for shot run and digitisation as key drivers, with its solution built around its Equios Art and UX software and inkjet printing technologies including its next-generation Truepress Jet 520NX which is designed for multiple applications including newspapers, books, statements and direct mail, and its Truepress Jet 520HD which is able to print directly onto offset coated stock thanks to its exclusive SC ink, which it says is the only aqueous ink that can print onto coated stock without the need to prime.

Digital print developers Ricoh, Konica Minolta and Canon all focused on the huge market potential of print outside of documents and marketing collateral. Ricoh says sign and display, labels and packaging, and textiles are all areas where its technologies will enable printers to exploit opportunities. Amongst its Igas exhibits will be its new its new 95ppm Pro C7200S with fifth station, and its new digital sub $10,000 T-shirt printer Ri100.

Konica Minolta says only one per cent of packaging print and four per cent of textile printing is currently digital, highlighting the opportunity. At the show it will have its new B2 inkjet KM-1 AccurioJet which will be shown with inline finishing. It will also have its MGI JetVarnish digital embellishment system, as well as its digital label press.

Canon sees digital packaging and signage growing rapidly, along with graphic arts printing. It too will be promoting the smart factory through its Prisma workflow, and will gave a book on demand printing demo in its commercial zone. Its theme will be Print and Beyond, with the company noting print is offering unprecedented value. Visitors will also get the chance to see the latest developments on B2 Voyager sheetfed inkjet printer.

Miyakoshi is similarly targeting new digital markets of flexible packaging, folding cartons, fabric, textiles and home decor. It will launch a high quality 1200x1200dpi water based inkjet press which prints at 200 metres a minute, and a new digital flexor press with the same resolution to print between 12 and 150 microns.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter