Businesses are increasingly seeing cost-effective textiles printers as an effective value add, with a NSW zoo installing one to print promotional items.

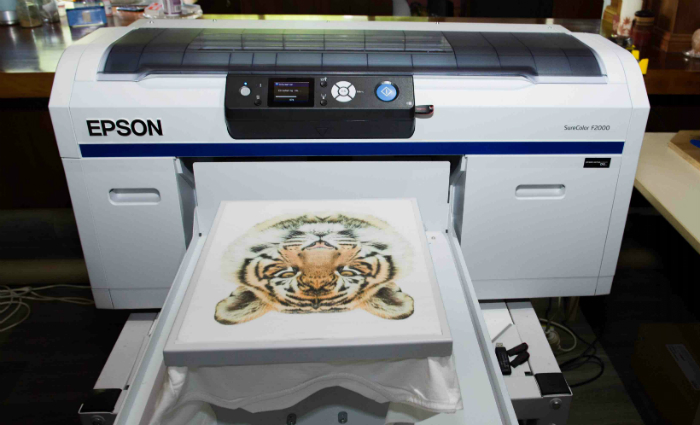

Mogo Zoo is using a new Epson SureColor SC-F2000 to print branded t-shirts and carry bags in-house that it used to outsource to specialist manufacturers.

Spokesman Clive Brookbanks says the printer has exceeded expectations and given the zoo flexibility in purchasing, design and quantities to match the seasonality of the tourism industry.

“The downside to [outsourcing] was that we were required to order large quantities up front which had a considerable impact on cash flow and did not always fit in with the seasonality of our business,” he says.

“We found that by buying our own printer we were able to far better control the quantity and quality of t-shirts according to our needs, and increase the gross profit on the sale of the t-shirts.

[Related: More wide format news]

Brookbanks says the printer can produce 75 t-shirts in a day including pre and post treatment, and is so easy to use even one employee with minimal training can do the job.

“The primary factors in choosing the Epson SureColor SC-F2000 was the simplicity, quality and speed of the machine coupled with the minimal training and experience required when it came to garment printing,” he says.

“Being a Zoo we were looking for a printer that could reproduce accurate, high-resolution images of our animals. This was important due to the relationship that our visitors develop with the animals.

“Additionally the product was then immediately on the shelf and available for sale.”

Epson says its latest textiles printing technology is providing printers with the ability to print with superior quality, performance and reliability when imaging cloth, garments and merchandise.

It says prints can be made to pre-cut fabric or finished garments, with a small heat press used to 'fix' the dye.

Epson sign and display national business development manager Ryan Warby says the SC-F2000 is targeted at a range of users from small garment print shops to the much larger print production houses, specialist retailers and even department stores.

“We have seen single SC-F2000s used to produce custom merchandise and clothes in retail environments while multiple machines have been combined for higher volume production,” he says.

“SC-F2000 users have been unanimously impressed by the unit’s quality, reliability, flexibility and low maintenance requirements.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter