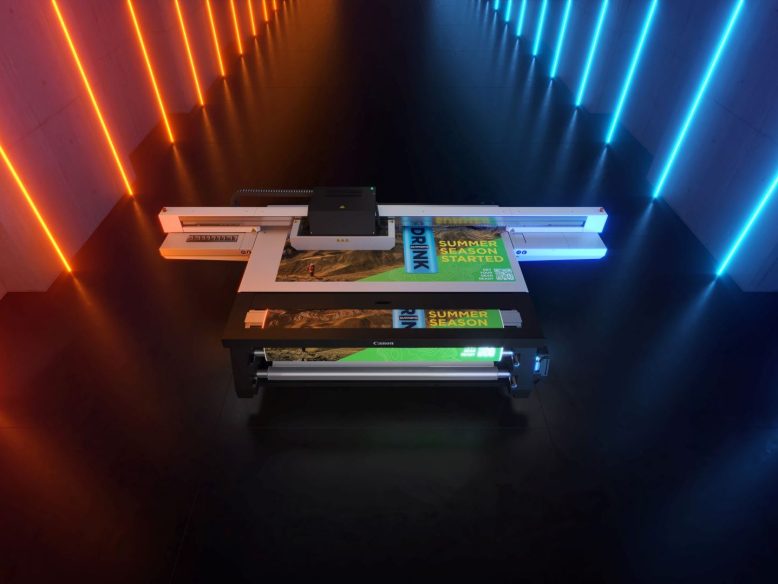

Canon has added its FLXflow technology to the Arizona 1300 series, which brings new productivity and performance features to the flatbed printer series. The company made this announcement at Printing United.

Previously known as FLOW technology, the new FLXflow offers not only the original ‘hold’ functionality, which helps to hold media down on the flatbed table, but also the new optional ‘float’ and ‘instant switch’ functionalities to improve media handling.

This allows Arizona users to benefit from enhanced productivity, print quality and application versatility thanks to FLXflow, a range of print modes, ease of use, workflow optimisation and UV-LED curing technology.

Catering to growing mid-volume operations, the Arizona 1300 FLXflow supports a wide variety of substrates and applications. This enables large format graphics printers and other print service providers (PSPs) to offer customers a wide range of applications for the retail, interior décor, packaging, and industrial market segments more efficiently.

The new ‘float’ functionality pushes air from the table upwards to create a cushion, enabling the easy positioning of heavy or challenging substrates and reducing the risk of media damage or waste. It also results in the smoother registration of all types of media, with a ‘floating without drifting’ functionality enabling several pieces of media to be precisely positioned at the same time.

The ‘instant switch’ functionality allows the operator to easily change from ‘hold’ to ‘float’ by using the foot pedal(s) for simple operability of the printer, making it easy to remove media from the table.

Arizona 1300 FLXflow customers can also take advantage of the Advanced Image Layout Controls, which allow last-minute adjustments at the printer, giving additional flexibility when positioning substrates on the table and reducing waste of expensive materials. Productivity is further enhanced by service support tools such as PRISMAservice, which provides predictive maintenance and facilitates authorised remote assistance by qualified service technicians to increase uptime.

Customers of the current Arizona 1300 series with FLOW technology can upgrade their printer to the latest version with FLXflow technology, including the optional Float and Instant Switch functionalities.

Upgrades also include features like the Advanced Image Layout Controls. They can also add PRISMA XL Suite workflow software to provide a preview function, which allows users to see what the final product will look like before it’s printed while allowing them to make any necessary adjustments.

This makes it possible to preview complex, multi-layered, textured jobs and to provide cost estimates before printing, thus saving time.

“At Canon, we’re focused on the continuous development of our flatbed technology by working closely with the market and our customers to evolve our products, from our printer ranges to the software that supports them,” Canon Production Printing Australia head of sales and professional services Steven Badger said.

“With that in mind, we’re now extending the FLXflow technology from the Arizona 2300 series, announced in March this year, to the Arizona 1300 series, giving even more of our customers the capability to be more versatile and deliver high-quality applications with even greater workflow efficiency and productivity.

“And with its added ‘Float’ capability, our FLXflow technology makes life much easier for operators to handle irregular or heavy substrates, opening up opportunities to produce an even wider range of applications.”

Available with the Arizona 1300 FLXflow is PRISMAelevate XL, which enables layered printing up to a height of 4 mm to help customers create stand-out, tactile artwork for elevated print applications that enhance and expand their product offering.

It enables customers to explore new applications, such as high-value, textured, permanent signage, product decoration, awards, décor materials and package prototyping, as well as applications for the visually impaired.

PRISMAelevate XL software makes prints durable without additional finishing steps, such as lamination, coating or spray varnishing, and results in less waste and higher production efficiency.

Offering reduced waste and lower energy consumption than its predecessors, the Arizona 1300 FLXflow requires less masking and underlays to hold media in place, resulting in less waste.

As LED-UV printers, the series also consumes at least 15 per cent less energy compared with its UV-halide predecessors, and offers power-saving features such as first-time-right printing and instant-on functionality. Its inks are UL GREENGUARD Gold certified, which ensures prints are safe for use in sensitive environments such as hospitals, schools and other public places.

Customers can also take advantage of Canon’s remanufacturing programme, where they can trade in their Arizona printers when purchasing a replacement. These older systems are inspected, serviced and prepared for sale as refurbished printers, further extending the lifespan of the Arizona.

The Arizona 1300 FLXflow is available from accredited partners as well as from Canon’s direct sales organisations.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter