Above: Christoph Gamper presenting at the Durst press conference at drupa 2024

Durst has launched products across five key platforms at drupa 2024 including large format, label printing, water-based printing, digital corrugated printing, and folding carton production.

P5 SMP (Super Multi Pass)

With the introduction of the P5 SMP, Durst is expanding its successful P5 Large Format Printing portfolio launched in 2018 for applications in the Sign & Display, POP/POS, Corrugated Packaging & Display and Industrial Decor sectors. Previewed at an event in March, the hybrid LED Super-Multi-Pass printing system combines efficiency and productivity with maximum versatility. With a print width of 3.5m and a maximum productivity of up to 2,000 square metres per hour, the P5 SMP achieves an annual capacity of 5 million square metres, setting a new benchmark for high-volume digital printing. As a hybrid solution, the P5 SMP can process both roll and sheet material and has the versatile functions of the P5 platform.

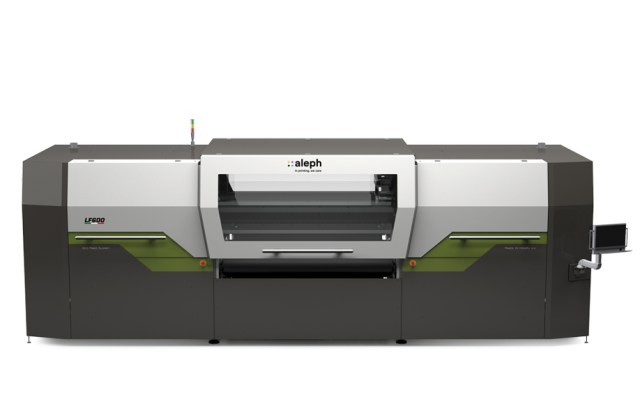

Aleph Laforte 600 Paper

Following the acquisition of Aleph in late 2023, Durst has expanded its position in the field of water-based and sustainable printing technologies. On display at drupa 2024 is the Aleph Laforte 600 Paper, which was designed for poster and billboard printing. In its most powerful configuration, the printing system achieves an output of 1,000 m2/h and reaches a new level of quality in poster and billboard printing with six colours and 1,200 dpi.

KJet

Durst has launched the KJet at drupa 2024 – the successor to the XJet. The KJet is a new hybrid solution for label printing and is the second product developed in conjunction with Italian family-owned manufacturer OMET. Previewed in March, the KJet is an end-to-end solution that combines OMET’s dual servo flexo printing units with Durst’s state-of-the-art RSCi inkjet technology. In addition, modules for finishing and further processing such as cold foil stamping or die-cutting units can be integrated into the KJet. This flexibility opens up an enormously broad application portfolio for the KJet. The configuration of the KJet is tailored to the specific requirements of each customer.

Koenig & Bauer Durst VariJET 106

On display at an exhibition for the first time at drupa 2024, the VariJET 106 is a significant innovation from the Koenig & Bauer Durst joint venture, which will pave the way for the digitalization of industrial folding carton production. The VariJET 106 was first announced in 2021, and uses water-based inks, so that primary packaging for food can be produced. However, the VariJET 106 is also a promising solution for applications in the pharmaceutical, cosmetics and tobacco industries for the economical production of short to medium runs and individualized packaging.

The VariJET 106 covers the B1 format and achieves a printing speed of 5,500 sheets per hour. The monthly print volume ranges from 500,000 to more than 1 million B1 sheets. Thanks to its hybrid design, several finishing units can be optionally integrated into the VariJET. In this way, the VariJET 106 becomes an end-to-end solution that enables economical and fast production of high-quality jobs.

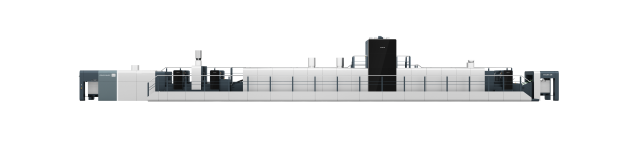

Koenig & Bauer Durst Delta SPC 130

What was missing in industrial digital corrugated printing until now was the colour white. Durst is once again taking on a pioneering role in the industry and is launching a water-based white ink for the Koneg & Bauer Durst Delta SPC 130. The use of white with extremely high opacity on brown corrugated board opens up new design possibilities and enhances transport packaging. By overprinting white, a significantly improved image quality is achieved on almost all topliners and at the same time an exact match to spot colours. All inks and fluids used in the Delta SPC 130 meet the current and future requirements of the food industry. The drupa line-up from Koenig & Bauer Durst was revealed in late April.

Durst CEO and co-owner, Christoph Gamper told journalists at the company’s drupa press conference that the “little big company” now has over 1000 staff and 295 registered patents.

“We closed our year a couple of weeks ago with sales revenue of 360 million Euros, shipping 2.2 million litres of ink with 320 service engineers across 33 subsidiaries around the world,” Gamper said.

“We invest 7.5 to 8 per cent of our revenue back into research and development, and we have 4000 installations in 72 countries.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter