The COVID-19 pandemic has posed enormous challenges for the world and for the entire print media industry.

In mitigating the situation, Heidelberg has amped up the use of intelligent or digitised service concepts and offerings to deliver solutions to its customers.

In Germany, the company had to provide maintenance despite contact restrictions at Kohlhammer.

As such, Heidelberg recently presented its extended range of contracts, known as Print Site Contracts, to ensure that the potential of its equipment is exploited in practical operation.

It demonstrated the capability at W. Kohlhammer Druckerei GmbH + Co KG in Stuttgart where the company serviced three Speedmaster XL 106 eight-colour presses in a quick turn-around time.

Within three weekends, three maintenance sessions, a press check, and overhauls of individual components were carried out under challenging conditions in order to maintain the presses’ full production capacity.

The company also utilised digitisaiton in an unusual Speedmaster installation at B&K Offsetdruck GmbH in Germany.

When the installation plan for the new Speedmaster XL 106 ten-colour perfecting press for B&K Offsetdruck GmbH was scheduled to take four weeks, nobody imagined how much the Corona pandemic would affect business and private life.

The press is one of three that was supplied by a local consignment warehouse through a subscription contract. Not only was it necessary to install the machine on time despite the difficult conditions, but there was also a need to create the conditions for supplier-controlled inventory management and to train the customer’s team accordingly.

The challenge was mastered in a cooperative partnership with the customer and the machines in Ottersweier continue to run at full speed.

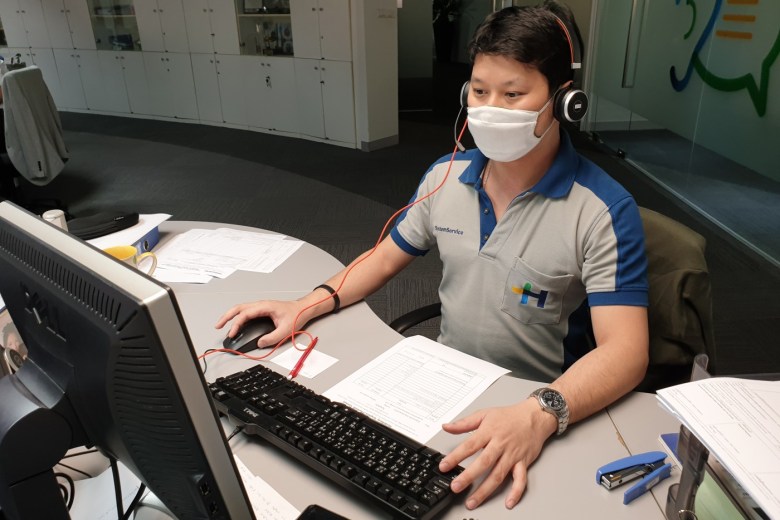

In South East Asia, in spite of the lockdown, Heidelberg Thailand provides full professional service and support.

The team has proactively developed new procedures and has adapted existing ones to meet all local regulations and customer safety requirements while ensuring the best possible support.

This has enabled the team to perform installations, carry out maintenance work and solve problems remotely, even in remote locations.

For example, when the lockdown in Malaysia began on March 18, the teams were able to support customers with various issues thanks to the digital connection of the machines to the Heidelberg cloud.

“Where on-site visits were not possible or feasible, the Heidelberg teams worked directly with customers in the Service Center to analyse and resolve problems remotely. Among many others, they were able to bring machines back into production where errors occurred in the pile delivery or in the positioning of the delivery grippers,” the company said.

Heidelberg employees in Indonesia have also worked hard to solve critical problems during the lockdown.

“The Heidelberg support teams Indonesia carries out the service on site and follows all government regulations and protocols related to COVID-19. Some of the engineers are on standby at home to contact customers remotely if they need assistance,” the company added.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter