Sustainability is no longer a side initiative – it’s a core business imperative. Brands, governments, and consumers alike are demanding greater environmental accountability.

In response, HP Indigo has reimagined what’s possible in digital printing, offering a powerful blend of efficiency, compliance, and circularity to drive measurable sustainability gains.

Leading with purpose and proof

With the print industry facing mounting pressure around Scope 3 emissions, waste reduction, and material circularity, HP Indigo offers proven solutions backed by independent certifications and measurable outcomes.

HP Indigo’s digital presses are manufactured with carbon neutrality from cradle to gate, and the company committing to operate with 100 per cent renewable energy by 2025. These milestones are aligned with HP’s global goals, which target net-zero carbon emissions by 2040 and a 50 per cent use of recycled, reused, or renewable materials in shipments by 2030.

Technology that reduces waste and CO₂

HP Indigo digital presses are engineered to reduce setup media waste by up to 90 per cent compared to analog methods. For example, the HP Indigo 6K press running 300 jobs per month can save up to 70km of media – the equivalent to $9,000 per month in material savings and significant carbon footprint reduction.

Through on-demand printing with no minimum orders, brands and converters can reduce overproduction, inventory waste, and transport emissions. A full CO₂ impact calculator is available upon request to support customers in measuring their emissions by press, job, and country-specific energy sources.

Designed for circularity

HP Indigo is investing in sustainable design, not just efficiency. The presses feature:

- Reused parts through a growing Certified Pre-Owned (CPO) program

- Recycled Imaging Oil (RIO) systems to minimise consumable waste

- Take-back programs for ink cartridges and press components across EU, UK, Australia and New Zealand

- Support for FSC-certified and post-consumer recycled substrates

- In FY22, 17 per cent of all HP Indigo press sales were CPO units, and more than 1,600 tonnes of consumables were diverted from landfill through HP Planet Partners.

Sustainable substrates and composability

HP Indigo enables printing on a wide range of eco-certified substrates, including recyclable labels, compostable flexible packaging, rPET liners, and reduced-weight label stocks. This flexibility supports brands’ goals to comply with EU circular economy regulations and achieve recyclability, compostability, or reuse without redesigning packaging supply chains.

Compliance built in

HP Indigo is proactive about meeting evolving regulatory frameworks. Its inks:

- Contain no hazardous air pollutants (HAPs)

- Meet the French mineral oil (MOAH/ MOSH) ban taking effect in 2025

- Are transitioning to PFAS-free formulations in advance of US and EU bans in 2026–2027

- Have built-in VOC capture systems for emissions control and site compliance.

Sustainability meets automation

HP Indigo’s PrintOS Suite delivers measurable gains in sustainability through automation and analytics. Tools such as Color Beat and Substrate Manager reduce setup time and media waste, while Site Flow enables distributed printing and minimises shipping-related emissions.

With PrintOS, converters and brands can optimise energy usage, consumables, and logistics – further aligning print operations with ESG goals.

Empowering printers and converters alike

The shift to sustainable printing is not only about compliance – it’s about creating value.

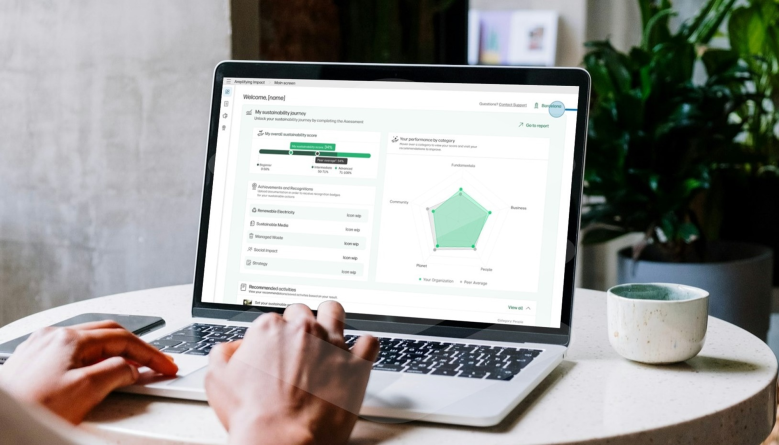

HP has developed a solution for this as part of its Print OS production operating system – the HP Sustainability Amplifier. Available to anyone with a Print OS account, this programme is designed to empower printers and converters to achieve environmental goals and deliver more sustainable prints to their own customers.

“Sustainability is no longer optional; it’s a business imperative,” said Carlos Lahoz, head of sustainability strategy at HP Industrial Print.

“HP Sustainability Amplifier is here to help you lead with purpose, offering tools, insights, and recognition to advance your sustainability journey. HP PrintOS Sustainability Amplifier helps you assess your current sustainability status and provides actionable insights to boost your impact. At the same time, you can tap into additional resources and get recognised by HP for the work you’re doing in this area.”

HP Indigo empowers converters to win business from sustainability-driven brands, while helping those brands hit critical KPIs in waste, carbon, and circularity.

By printing on demand, consolidating SKUs, and choosing sustainable substrates, brands using Indigo are well-positioned to meet both internal ESG targets and external regulations without compromising quality or flexibility.

This first appeared in the August edition of ProPrint magazine.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter