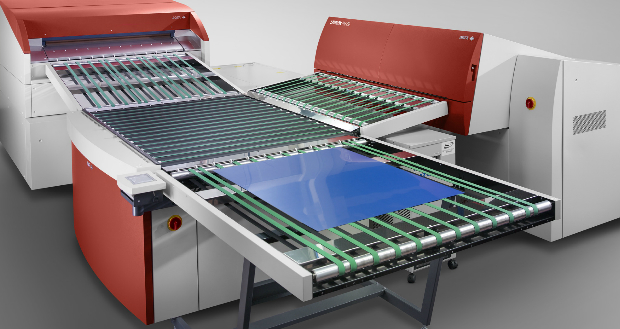

The new product is a consistent further development of the UVSetter 710, which has already been sold about 250 times to date. The fully automation is the perfect choice for customers who require fully automated plate production, processing up to three different plate formats in three or, optionally, five magazines. The maximum plate size is 940x1150mm.

The interleaving paper is removed automatically. Before exposure, the plate can be punched using a maximum of two different inline systems, providing maximum register accuracy during printing. The flat bed exposure table holds the plate via a vacuum. After imaging, the plates are transferred to the online processor. It is thus an ideal solution for ‘unattended’ production.

Each of the five plate cassettes can accommodate up to 100 plates with a thickness of 0.30 mm or 150 plates with a thickness of 0.15 mm; the plates can be loaded into the Autoloader under daylight conditions.

Another convenient feature is the compact design of the UV-Setter 710-f2 Fully Automatic, which requires only little space in the production room.

Jürgen Szibbat, basysPrint international sales and marketing manager and member of the board, “We have found a solution for those amongst our customers who have required a higher degree of automation and a better throughout in plate production for commercial printing. The first five units have already been installed.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter