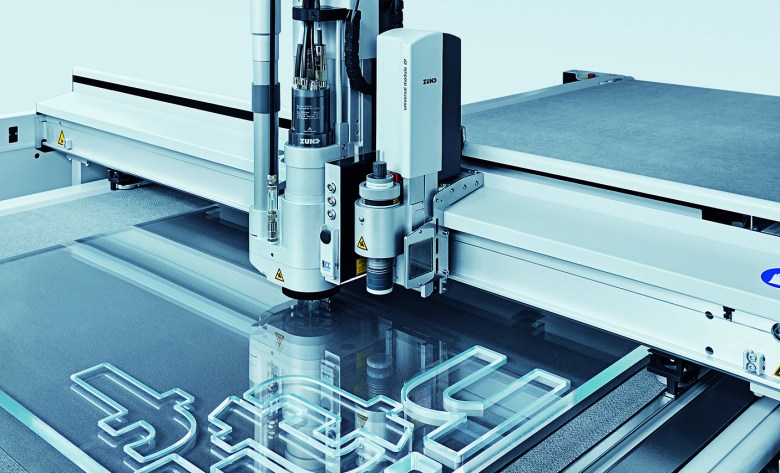

A new high-powered RM-L router option is now available in Australia for the popular Zünd G3 and D3 cutters, through Starleaton.

According to Starleaton, the spindle delivers 3.6kW of processing power for acrylics, polycarbonates, ACM, Foam-PVC and MDF, making heavy-duty routing up to 50mm depth more efficient.

The company says that by water-cooling the spindle, and introducing a dust extraction system alongside the router module’s minimal quantity lubrication system (MQL), very little heat is generated during routing, while the work area remains clean. According to Starleaton and Zünd, this contributes to overall productivity and allows for greater processing speeds, acceleration, and bit life.

Starleaton says that an intelligent surface compensation system determines the thickness of the material and detects inconsistencies. During processing, the system reliably compensates for any variances by making the necessary depth adjustments, which Starleaton says is important for engraving applications.

Alongside this, Starleaton explains that the ARC HSK automatic tool changer takes care of handling and changing router bits; the magazine can accommodate up to eight different preloaded collet holders. Fully automated tool changing increases overall levels of production automation and throughput, which positively impacts productivity. According to Starleaton, this is best used for workflows that involve many different types of custom or complex designs that call for several different bit sizes and types.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter