Perth based printer iPrintPlus no longer needs to send as much finishing work offsite with five new pieces of Horizon equipment installed

Perth family owned digital printer iPrintPlus once had to send tricky finishing jobs offsite including to the east coast but since installing the Horizon finishing equipment that need has largely disappeared.

Marvi Douglas and her sister Lorena have worked in the business since it first started as Optima Digital in 2007, which shortly after changed to iPrintPlus.Three years ago when the original owner wanted to retire, Marvi, Lorena and their brother Omar bought him out.

They specialise in colour and black and white digital printing of photo books, self-published author books, school yearbooks, company share registry documentation and any other digital printing that is needed with the bulk of their work coming through print brokers or direct orders.

When the trio purchased the business they installed a Horizon PUR perfect binder but when that and some other pieces of finishing gear they had were up for renewal it got them thinking about exactly what their finishing needs were.

Currie Group’s WA State Manager Adrian Dixon visited their Osborne Park print shop to show a few options and interested to learn more they headed to Melbourne to see the gear in action in the Currie Group showroom.

Realising that upgrading the equipment and adding a hard case binding system, which they did not already have, stood to save the business time and money and increase their product offering to clients they went ahead with a full range solution.

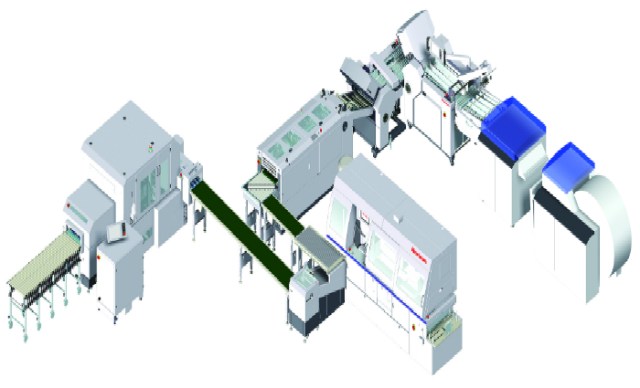

In all the new set up includes a Horizon HOF-400 stitching line and a Horizon CRF-362 creaser-folder. They also added a Horizon BQ-270 EVA binder, a Horizon HCB-2 Case binding system and a Horizon BQ-280 PUR perfect binder.

Marvi says she added the hard case binding machine which finishes hard cases for books including photo albums and family tree pictorials to complement the PUR perfect binder with the Horizon saddle stitcher completing the picture.

“The 2 case system is purely used to create hard case covers for books. We do family tree books, and photo books. We might do 50 hard cover books and then the customer might want 10 finished with a hard case,” Marvi told ProPrint.

“We have a company here in Perth that does hard case binding but it was very hard to get anything done when there is a small quantity. We wouldn’t do a large quantity on that machine because it would take far too long but to just do 10 or 20 copies it works perfectly.

“We found that it was so hard to actually get them bound because they were so expensive for just a few.

“So, we thought we would get our own machine in. It’s the base machine but we create quite a few nice books out of that.”

Marvi says she first saw the PUR perfect binder at drupa in Germany three years ago. She is still considering returning to drupa in 2020 but says she has the majority of the equipment she needs for now.

Adrian Dixon adds, “A key part of our client’s decision making, apart from the quality of the Horizon equipment ‘of course’, was the local service support and back up.

“With Currie Group’s strong local representation in Perth, with a team of six staff including three technicians plus local warehousing for spare parts, we were able to give iPrintPlus a seamless journey from installation to full production.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter