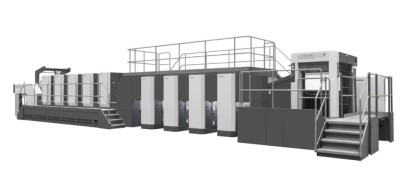

CMYKhub has unveiled its Komori Lithrone GX40RP at the company’s soon to be open, state-of-the-art headquarters in Melbourne.

The Komori Lithrone GX40RP is a two-sided press with high productivity, stable printing, no sheet flipping, reduced waste, and eco-conscious functions.

The press is the first of two machines making their debut at CMYKhub’s new 7000sqm purpose-built facility, located in Keilor Park near Tullamarine Airport.

The company has also installed a Canon varioPRINT iX3200 B3 press, which was purchased last year at drupa.

The new premises will represent twice the space of CMKYhub’s current premises, which is currently spread over six locations in Heidelberg, Melbourne. The new headquarters on Wright Road will also feature 500sqm of office space across two levels.

CMYKhub CEO Dayne Nankervis told Sprinter the Komori had been in storage for two years in anticipation of the new facility’s opening.

“Our new Komori replaced an existing machine that will also still be in use at Keilor Park. It’s 30 per cent faster than its predecessor,” Nankervis said.

The area for the new press has been ergonomically designed around the machine, featuring a built-in pit to optimise working conditions for the operators.

“One of the main advantages of the Komori is the elimination of sheet flipping, which significantly reduces downtime,” Nankervis said.

Another feature of the Komori is its advanced camera system, which can detect inconsistencies such as blemishes, or roller marks during production.

“It captures an image of every sheet and compares it directly to the original PDF file. If there are any inconsistencies, the system immediately alerts us. That level of quality control is a major upgrade – something we don’t have on our older presses,” Nankervis explained.

According to Nankervis, the new Komori and its predecessor will both be running at the new Keilor Park site as the company aims to ensure “100 per cent redundancy into the new facility”.

“While this new press is more advanced and will take on the bulk of the work, the existing press will remain operational and productive. That way, if one press goes down, production doesn’t stop. Both presses use H-UV technology, although the new one runs on LED, which makes it even more efficient.”

Nankervis said the new facility’s layout has been designed for efficient production flow. The factory’s consolidated operations aims to create a purpose-built, climate-controlled, and sustainable facility.

“We’re entering this new site with a new offset machine, a new digital press, and we’re bringing over all our existing equipment. These additions will increase our capacity and improve our ability to meet turnaround times. We’re also installing a new laminating machine, two new folding machines, several wide-format machines, and a fabric printer,” Nankervis said.

“After 18 years in operation, we’ve taken the opportunity with this new site to redesign the factory layout.

“For the first time, we’ve been able to create designated areas for departments such as digital, offset, bookbinding, labels, and packaging. We’re also adding new departments like fabric printing and soft signage via EFI. Where there’s a value-add for clients, we’ll continue to invest.”

CMYKhub’s new facility is scheduled for occupancy from mid-September.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter