While digital production of labels has been around for a while, new advances in technology have created a buzz around printing labels digitally – but what market segments are demanding the digital manufacturing of labels?

What is the image quality like, and does it matter, or more to the point, when does and doesn’t it matter? Is speed of delivery a factor that can be set against high-end premium look and feel?

For label print business owners the choice of which printer and which technology can be bewildering. So, what are the main options available to label business owners who are considering entering the digital label print business?

What the vendors say

HP Indigo WS6800

According to Mark Daws, general manager, A/NZ, of the Currie Group’s labelling and packaging division, pressure-sensitive labels are still the dominant driver in digital print, compared to flexible packaging and folding cartons. “In many cases it is the brands and customers demanding it. They all have a need to go to market in the fastest time possible, whilst enjoying the flexibility of an agile supply chain to help manage their products.”

Daws observes that all market verticals are driving the need for digital, from high-value, short-run wine labels, to FMCG, pharmaceutical and so on. “It is now that flexible packaging and carton converters can see the value it brings to their own customers, that we are beginning to see the shift into these verticals.”

For printers seeking to enter the digitally printed labels market, Daws has the following advice: “It is important that they consider their options carefully. The A/NZ label industry is quality driven, and the small size of the market means that, for the most part, converters are addressing multiple verticals (FMCG, healthcare, wine, and so on), so they do need to consider printing technology that can address all of these markets – from a quality perspective, substrate compatibility and similar. The majority of converters do not have the luxury of addressing a single application, and therefore they are forced to be all things to their customers.”

“There are many converters that still use older letterpress machines, so digital can be an easier printing method to convert to, given that there is not the requirement to completely change existing tooling, which can prove costly,” he says.

Daws sees the current HP Indigo WS6800 as ‘the product of choice’ for entering into digital print in labels and packaging applications. “Having evolved from the earlier WS6000 press, the current platform offers the flexibility to run media from 12micron to 450micron, allowing our customers to branch into new verticals such as shrink sleeves, IML, flexible packaging and cartons, in addition to pressure-sensitive.

“Coming with an inline priming module (ILP), it means that any off-the-shelf material can be used on the press. The latest features include a fully automated colour engine which removes the need for operator intervention by continually colour-adjusting on-the-fly.”

Daws explains that media and custom colours can now be accurately fingerprinted using 3D colour calibration to achieve the highest range of colour reproduction, integrity and repeatability throughout the press lifecycle. He says Indigo’s new ElectroInk offerings include lightfast inks, high-opacity Premium White, high-slip white ink for shrink sleeves, invisible Red – which alongside the 97 per cent of Pantone colour reproduction the press can achieve – provide a solution to all application needs.

“Whether it is running offline, inline or hybrid options, with the AB Graphics range of Digicon digital converting lines, or alongside specialty finishing lines from Karlville for shrink sleeves and lamination, or Schobertechnologies’ RSM Varicut converting for IML applications, Currie Group provides a full range of end-to-end workflow to suit any type of application need,” he adds.

Xeikon

Xeikon, now a part of the Flint Group, is represented locally by Absolute Electronics. Filip Weyman, director of segment marketing and business development for labels and packaging at Xeikon, sees general interest by printers for digital label printing in all end-use applications (food, industrial, wines and spirits, beverage, pharmaceuticals, health and beauty).

However, with digital labels, he believes volumes vary widely by segment. For example, pharmaceuticals are mainly smaller runs when expressed in square metres, ‘but this is logical when looking at the nature of these labels’.

Weymans says, “Overall, the digital presses fit with any kind of flexo or conventional printer. In the case that printers add the digital press, it is mainly to complement their conventional processes rather than generating new business driven by a new business model. Which means they do not necessarily capture the full benefit of the digital capabilities, although there are exceptions.

“What you do see is that there is a vacuum in the market that allows new label company startups. This is created due to the consolidation that is taking place in A/NZ and the market needs which are not being served by the current industry. These new startups are businesses geared around flexibility, short delivery, short runs.”

Weymans says studies show consistently that the main capability of digital label printers lies in four-colour (plus-one) printing, and it is generally unwise to over-invest at the start. The same principle applies to printer speed. Going for the high-speed machines promoted by vendors might result in a disappointment when printers see speeds dramatically impacted by the number of colours, dimension of the label, ink coverage or resolution. “So appointing a critical project manager is never a bad investment in order to achieve the best solution that fits your business.”

He notes that Xeikon offers seven label presses that differ in speed, print width, investment cost and operational cost. As well, Xeikon offers end-to-end solutions, including workflow, converting equipment and printing press.

Also on offer are application-tuned toners which serve specific needs, such as lightfast, durable, odourless, food-approved, durable, and toners free of mineral oil or UV curable components.

“All our presses are based on five-print stations which are full rotary. This brings guaranteed productivity and allows you to print labels of any size,” he notes.

Weymans says the dry toner used on the presses is optimal for standard substrates used in flexo. There is no need for priming or pre-treatment, and there is no corona as with liquid toner or UV inkjet. “It keeps the cost down, avoids complexity and reduces working capital.”

Epson SurePress

According to Epson Australia’s general manager, business division, Craig Heckenberg, high quality, short-run customised labels, economically produced, are in huge demand in the food and beverage, wine, ‘nutraceuticals’, pharmaceuticals, personal care and industrial markets.

It is a lucrative window for entry – but Heckenberg has some advice for printers considering an expansion in this direction. “Do your research regarding total running costs and ongoing service requirements, and include realistic downtimes. Today’s digital offerings are varied and not one type of technology is the same.

“Inkjet technology delivers the speed and quality without the need to use pre-coated substrates (as required by other technologies). For other types of printers looking at digital labels, ensure you are thorough with your finishing requirements,” he says.

Heckenberg sees multiple advantages for label converters to spread their wings into digital technology. It is easy to switch from analogue print jobs, due to wide substrate support and high image quality. Colour matching is simple and colour calibration can be completed in a short time. For repeat orders, colour repeatability is simple and accurate. “Non-contact inkjet printing means the texture of substrates such as uncoated paper can be exploited.”

As to non-label printers seeking to enter the digital label sphere, simplicity of operation is a big plus, says Heckenberg. “Even operators printing labels for the first time can easily master it. It is possible to perform printing operations that are difficult or not possible on analogue label presses, such as long lengths or VDP (variable data printing), so it is easy to differentiate service offerings.”

Epson’s SurePress L-4033 has been a success with more than 1,000 companies investing globally, due to the high-quality print, affordable entry-point and Epson’s support. Heckenberg reports that Epson customers are expanding their digital jobs against analogue by an average of 21 per cent, with short-run customisation and VDP being the key drivers.

Additionally, the Epson digital label press range is continuing to expand with the SurePress L-6034VW UV LED just released. The L-603 has the special ability to print digital varnish on a wide range of substrates, while automatic head wiping, nozzle checking and rewind functions reduce the need for constant monitoring.

“For Australian label convertors, investing in digital is now in the phase of ‘when’, not ‘if’ and growing. Other print businesses are looking at digital label printing as a differentiator and additional revenue streams,” Heckenberg sums up.

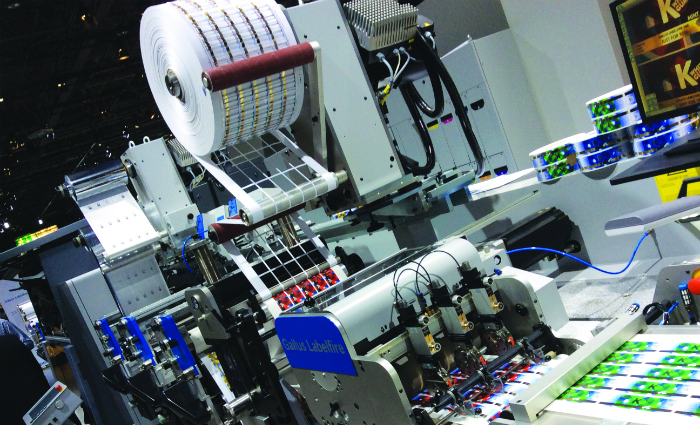

Gallus launches digital Labelfire

Gallus has launched its inkjet digital press the Labelfire, which uses the Fujifilm technology that parent Heidelberg has on its Primefire digital folding carton press. Heidelberg’s biggest shareholder and former Gallus owner Ferdinand Ruesch said that the new press was three times faster than anything else on the market. He says, “The speed is tremendous, but that is only part of the story. It is its inline capabilities that also set the Labelfire apart. The Labelfire will rip, print, convert, embellish and finish in one pass. It can have multiple embellishing options including foiling and flexo both of them upstream or downstream of the print.

“And for us the press is only part of the solution, label printing is industrial printing, a full digital end to end solution is where label printers will win, and we alone are able to deliver this. For the printer this means just one point of contact, rather than dealing with multiple vendors.”

Gallus aims to be number one in the digital label print market with the Labelfire, and believes its speed, quality, and inline production will enable it to overtake HP and Xeikon, although ‘not immediately.’

The Labelfire is based on the ECS granite press from Gallus, of which more than 400 have been sold around the world. James Rodden, general manager of Gallus Australia says, “There is no doubt that for Australian label printers looking for short run or variable data label printing the Labelfire is a must see. It will enable them to offer new solutions to their customers, and take their businesses forward.

This is reflected in the native (physical) resolution of 1,200 × 1,200 dpi with a droplet size of just 2 pl and up to 200 grey scale values, corresponding to a visual resolution of 2,400 × 2,400 dpi. The high physical resolution of the inkjet heads offers a real advantage, particularly when it comes to small symbols and characters as well as fine lines and gradients down to zero percent.

The smallest droplet size in the printing industry to date results in smooth, satin-finished surfaces, improved ink adhesion and curing and minimal ink consumption. Gallus says the inkjet print head enables seamless inkjet head stitching, resulting in a smooth print across the entire web. The combination of digital white, CMYK, the colour space enlargement colours orange, violet and green, as well as seven-colour separation mean the Gallus Labelfire press system can cover a large portion of the Pantone colour space. Print speed is 50 linear meters a minute on a 340mm web width.

Truepress JetL350UV

Screen Australia’s managing director Peter Scott identifies short-run and variable labels as the main candidates for digital printing, as there is no requirement to make plates and a lengthy press set-up as with flexo. “However, the economies of our Truepress JetL350UV digital label presses installed around the world are showing that longer runs can be produced more efficiently with digital too.”

With the options of inkjet, liquid toner and dry toner, Scott believes all have their attractions, “But our customers say that Screen inkjet can print more designs on a wider variety of stocks, and on varied web widths up to 350mm. Attention should also be paid to end-of line converting but there are numerous third-party solutions available, including Screen's JetConverter 350”.

His advice is to look at final productivity and true cost-per-label. “Flexo printers are telling us that the L350UV is actually faster and cheaper to run than flexo and other digital, apart from very long print runs of the same label. The ability to stream jobs one after the other without changing plates is a phenomenal production advantage. One UK customer, Springfield, ordered his third L350UV at drupa.”

Scott’s prognosis for the future of digitally printed labels is highly positive. “The quality is there, the demand is there, the hardware is there, the economics are there. I see the day when all-digital label producers will dominate, sending very long runs out for trade printing by flexo and gravure printers.”

CASE STUDY: Guru’s wise choice

At Guru Labels, located in Tuggerah on the NSW Central Coast, a strategic move to end outsourcing of work and produce digitally printed labels for the trade has been a milestone, with the company undergoing a major upgrade to provide the speed and flexibility demanded by printer customers, with a new Xeikon 3300 and GM finishing equpment.

Guru’s sales director Nicholas Lowe tells ProPrint the trade can indeed be quite demanding, wanting it all, and yesterday. “They want the highest quality at the lowest price and shortest turnaround times, and we are now able to provide that. We began with a turnaround of ten working days, we got that down to seven at the start of this year, and the goal was to reduce it five days from June, which we achieved.”

The family owned label company – Lowe’s wife Karen and daughter Emilie have roles at the business –has a staff of 16. Since its inception 15 years ago, the company has been fully digital.

Last year, after researching widely, the company invested in a new Xeikon 3030 toner-based roll-to-roll label press, complete with Australia’s first installed GM laser finishing unit. The Xeikon 3030 prints CMYK-plus-white, and has variable width up to 310mm by any length, a boon for printing repeats and banners. It features true 1200dpi at its top rated speed of 9.6m/min, can generate up to 190sq m/hour, and offers variable printing. It works with standard substrates, providing dry-toner printing that is lightfast and water resistant.

Lowe says the GM unit’s laser and conventional cutting systems deliver all the benefits of both technologies. Laser cutting eliminates tooling costs associated with dies, while in conventional cutting mode, the unit offers high speed operation for long runs. “It allows us to finish labels in any shape, size or design,” he says.

The new production room has enabled Guru to provide a premium service to the trade. Says Lowe: “We have a number of key markets, but the trade market is one we’re growing really aggressively. Before we put the equipment in, we had about 50 trade customers, and 14 months on, we have just under 500. Even with some of the very large runs, we’re producing them digitally in a competitive way. With the inline laser system, we keep the work here, and we get to control the consistency and quality.”

Lowe finds that overall label volumes at Guru are now spread across a lot more jobs, so the efficiencies provided by the GM line are a critical factor. “We can put different customer jobs across the web, nobody else can do that. So if it’s a certain stock that’s on for the day, and we’ve got 15 or 20 orders to go through, where we can, we gang them up across the web and the laser can handle cutting multiple shaped designs, all in the one hit.”

A web-to-print portal makes ordering quick and straightforward, which is a real attraction for trade customers, says Lowe. “Being digital, they pick any shape and size they want, and get their pricing straight away. We still do quotes manually, but most of our trade customers go to the portal, that’s our lowest price, and they get their quote in about 30 seconds.

“Ten-to-15 years ago, we used to sell labels three months in advance, with lots of finished stock waiting in the warehouse, but today speed is everything. If a competitor takes a day to do a quote, the chances are that companies like us have done the quote, done the artwork, signed the order form and started printing,” he says.

More broadly, Lowe finds digital labels are now fully accepted. “Everyone’s very comfortable with it. We all understand what compromises digital has regarding the matching of PMS colours, but it’s now accepted. The truth is that if you haven’t got into digital for labels, now is the time. I’m not saying it’s too late, but it’s getting there.”

CASE STUDY: Flexo house’s digital drawcard

At Rotoprint in Burleigh Heads on the Gold Coast, an Epson SurePress has brought digital label production to what was traditionally a flexographic label printing company. Since its introduction more than 18 months ago, the inkjet label press has brought in new business with fast turnarounds for labels on short runs up to around 1,000 impressions.

As clients’ orders grow to volumes above that mark, they are sent to the Queensland company’s Nilpeter flexo press line, explains Rotoprint’s owner and sales director Danny Bogatie.

Rotoprint wanted a bridge to the digital label market and the decision to select the SurePress was partly determined by Epson’s tried-and-true proofing credentials, says Bogatie, with much of the industry’s colour proofing in litho, flexo and gravure being done on Epson proofers.

“The technology being used in the machine is basically what’s being used in proofing, so colour representation and image enhancing on the SurePress is fantastic,” he tells ProPrint.

Another plus is that the SurePress is driven by an inhouse computer operator and does not require specialist printing or IT personnel, says Bogatie. Add to that the absence of click charges on the machine, and for Rotoprint, it was a winning formula.

Bogatie explains that for Rotoprint, a 14-year-old company with seven staff, “flexo label production is still our core activity, and we see digital as a catchment for smaller jobs that are then migrated to flexo as the client’s business with Rotoprint grows”.

Because of Epson’s proofing, work done on the SurePress can be readily switched to the Nilpeter without major colour tweaking.

Bogatie is a firm believer in the viability of flexographic label printing for the foreseeable future and there are no plans for Rotoprint to become a digital-only provider. The economies of scale are unchallenged, he maintains, stating that a run of one million labels on the Nilpeter press can be produced at the cost of 0.7 cents per label, and while it is too complex to put a similar unit cost on a ‘typical’ digital label, it would be nowhere near as low.

A new Nilpeter FB3, due to be installed shortly at Rotoprint, is expected to run at around 120 metres per minute on the production floor, although its rated top speed is 226 metres per minute. The Epson SurePress reaches around 12 metres per minute.

Rotoprint works in food, pharmaceuticals and ‘nutraceuticals’, and generally, the new products that are trialled at retail outlets tend to be in smaller consignments, which require shorter runs of labels. Once a product reaches consumer acceptance, and switches into mass-production, the label requirements become different, and lend themselves less to digital and more to flexo.

“That’s the reason we brought in the digital and it’s also the reason we’ll never get rid of the flexo,” says Bogatie. “The correlation between the two printing technologies works.”

Alpha targets new markets with Indigo

Sydney label printer Alpha Labels has broadened its customer base and slashed turnaround times by installing an HP Indigo as its first digital label printer. Alpha managing director David Poole says the new HP Indigo WS6600, installed last May, gives the company more flexibility and be able to print flexible packaging, sleeves, and folding cartons for the first time. “We are always looking for a competitive edge, as well as ways to provide better service to our customer base and potential new clients, and this has given us the opportunity to offer a real point of difference,” he says. “With the Indigo’s unrivalled speed and efficiency, we have been able to produce more work at a faster rate, without compromising the quality that our customers expect.”

Poole says he decided to get into digital to replace an old offset press as he saw runs the market changing and wanted to grow the company beyond labels into other kinds of packaging which were not possible with offset. “I have seen runs getting shorter and turnarounds getting tighter, customers are ordering less but more frequently,” he says.

He says the Indigo is already hauling in new work, winning the company a huge sequential numbering label job last year that would not have been possible on offset. Alpha is also using the Indigo to print flyers and other commercial print work to fill more of its clients’ needs.

Poole says the digital WS6600’s colour gamut will streamline the Alpha operations by eliminating the time required for colour separation, mounting plates on the machine, registration and colour-matching. With up to seven ink stations on the machine, high-resolution prints are now ready to go immediately and any changes can be manipulated on the spot.

Poole says the new machine will cut waste as its enhanced print quality reduces the margin for error and the higher throughput will also slash setup time between jobs, minimising the waste created when preparing the machine. It also supports several eco-certified substrates, as well as environmentally friendly primers, varnishes, and adhesives.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter