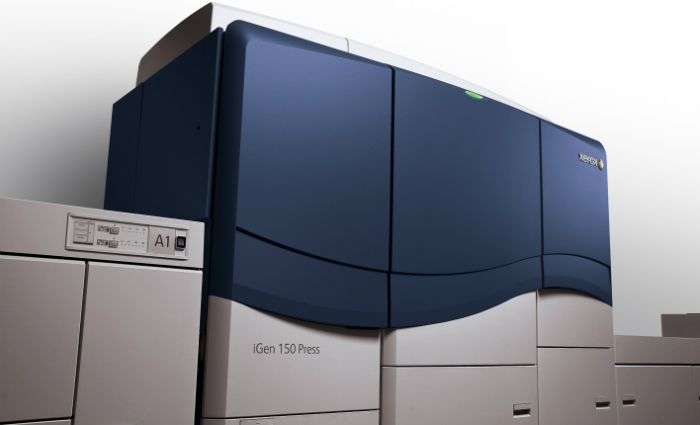

When Fuji Xerox unveiled the iGen 150 at drupa in May 2012 the digital press was billed as a higher grade version of the iGen4, which the company had released three years earlier.

Although the latter had quickly established itself in the marketplace as a reliable operator, the rapid growth and growing customer demand for personalised and short run on-demand printing meant that there was space for a press that could deliver the same high quality of print, but at a faster speed.

With a 25 per cent improvement in productivity for all paper sizes (compared to the iGen4), the iGen 150 perfectly fills the void, according to Mark Williams, Fuji Xerox Australia product marketing manager.

“The iGen range has always met the challenges of a changing industry and the iGen 150 is no different,” says Williams. “It was launched to offer customers profitable new business growth opportunities through a greater variety of applications, unrivalled efficiencies and productivity improvements, increased volumes and image quality capabilities that approach lithographic offset.”

Target market

The three primary market categories that the iGen 150 is targeted are offset complement/transfer, photo printing and variable data applications, according to Williams. This gives the machine a potentially broad range of customers encompassing commercial printers, quick print shops, traditional offset printers looking to move into digital, in-plant print shops and service bureau transactional printers.

Many of these customers had a significant input into the new direction that Fuji Xerox has taken with the iGen 150, says Williams.

“All of the enhancements seen in the iGen 150 have come from customers’ feedback and market trends in the graphic communications industry. Being a leader in this space requires ongoing feedback on how to offer profitable and growth opportunities,” he explains.

Technology

Although the basic technology underpinning the 150 has been taken from the iGen3 and the iGen4, the latest addition to the iGen family has a number of new capabilities. Most notably the iGen 150 has a significant speed bump over its predecessors, thanks in large part to the new sheet size of 660mm, which means that customers are capable of putting more content on the same sheet, says Williams.

“The raw speed of the iGen 150 is substantially faster when comparing to similar solutions on the market. Utilising the large sheet size of 660mm, speeds of up to 150 A4 sheets per minute are achieved, producing more sellable prints per hour and more short run jobs per shift.”

The machine’s running speed has been further enhanced thanks to the greater levels of automation that have been built into the iGen 150.

“Tasks that once required the time and attention of a dedicated press operator now happen automatically,” says Williams. “This means more press time running more jobs per shift, more consistency and more predictability. Combine this with the iGen 150’s outstanding image quality and you now have a press that requires less time and expense compared to an offset run – less overheads equals an improved bottom line.”

Productivity levels have also been boosted by the inclusion of a new stacker that enables the inline stacking of 660mm sheets.

Quality

When it comes to quality Williams says that the iGen 150, which uses Vertical Cavity Surface Emitting Laser (VCSEL) technology, is second to none. “The quality is outstanding – it rivals offset,” he claims. “The iGen 150 can handle jobs no other digital press has ever been able to tackle at full rates speeds.”

Williams’ claim is not without merit thanks to the iGen 150’s improved process controls and better front to back registration – not forgetting a new output resolution of 2,400×2,400dpi, new line screens and the use of matte dry ink, which expands the range of possible applications on the machine to prints that require a higher quality, such as catalogues and photo albums.

“Image quality is also about consistency in colour, registration and uniformity that enables print providers to offer new products that were once too expensive or too time consuming to produce in-house, and take on new work that was previously not possible,” adds Williams.

Market reception

Although the iGen 150 received a global launch in 2012 it wasn’t available to Australian customers until February 2013, with the press taking centre stage at PacPrint in May – the machine started shipping in April 2013. Some 12 months down the line Williams says that the response of the Australian market to machine has been ‘unprecedented’ with 13 orders already placed, and more anticipated as Fuji Xerox follows the positive reception the 150 enjoyed at PacPrint.

“The comments [we received] are around how we have listened to the market and developed a press that addresses the graphic communications challenge now, and in the future, through improving efficiencies and developing the capability to grow a profitable business,” says Williams. “The automation that is at the operators’ fingertips to maintain uptime and reduce print ready is at the forefront of the responses to date.”

Although sales targets for the machine are confidential William’s is prepared to reveal that the company measures its performance on year-on-year growth and for ‘this financial year there has been double digit growth all on the back of the iGen 150’.

He’s also coy when it comes to the cost of the new machine, explaining ‘it’s too difficult to respond due to the number of different configurations and solutions that are offered to the market. We recommend that customers contact their account manager who will engage one of our iGen sales specialists that are specifically responsible for the iGen platform’.

Service and spares

As you’d expect with any Fuji Xerox purchase, spares and consumables are readily available, with the company offering a service model that includes a combination of on-site, in-van and in-stores all backed up by a national parts and consumables warehouse.

Furthermore, all iGen engineers are equipped with the most common spares and consumables either in their service vehicles or a just a short drive away in one of the many district stores that the company maintains.

“Our iGen service and support strategy is the benchmark and one of the reasons why our customers invest with us,” says Williams. “The service model reflects our customer demand and challenges within an industry that is ever-changing. It includes a full service and maintenance agreement that offers standard and optional on-site our of hours SLA’s, as well as the ability for operators to self-manage with their own site stock and operator training on regular maintenance tasks.”

The iGen platform also has the ability to enable ‘notifications’ to be pushed to the company’s service specialists, providing what Williams’ describes as ‘pro-active maintenance and fault information in real-time that ensures maximum up time and reliability’.

Alternatives

HP Indigo 5600/7600

HP claims that the 5600 delivers ‘unmatched digital offset and photo quality with exceptional versatility and high productivity’. The manufacturer claims the press can handle more than two million colour pages or five million monochrome pages per month, with a top speed – using enhanced productivity mode (EPM) – of 90 A4 pages per minute. Offering new special effect capabilities—including raised print and textured effects—the 7600 can produce four million colour pages per month, and using EPM throughput of 160 colour pages per minute is achievable.

Price: on application

Contact: Currie Group

Kodak NexPress SE/SX

The NexPress SE range is capable of driving ‘more jobs per shift and more profits per page’ than its rivals, according to the manufacturer. Kodak’s SE3600 model boasts a top speed of 120 A4 pages per minute. The NexPress SX3900 – the top rated model in the SX range – has a duty cycle of 4,400,000 with a maximum speed (using the standard feeder) of 120 A4 pages per minute. Both the SE and the SX ranges feature the newly reformulated NexPress HD dry inks and Print Genius – Kodak’s suite of quality control tools and options that helps printers ‘manage and maintain peak quality’ throughout production runs.

Price: On application

Contact: Kodak

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter