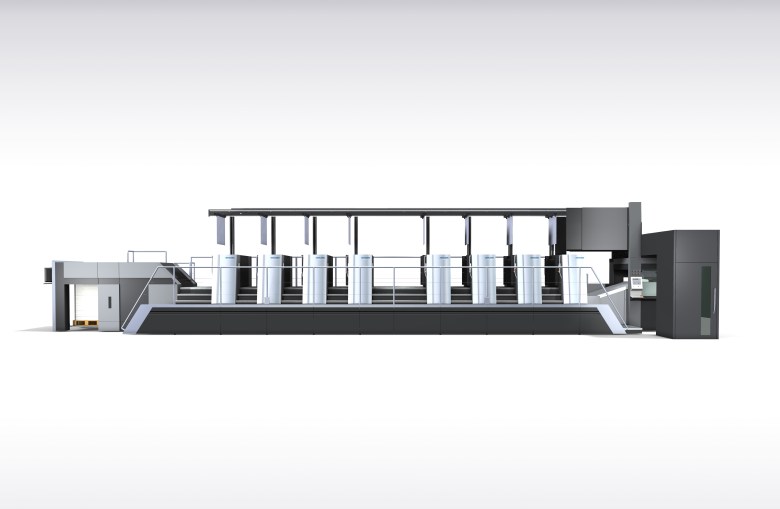

Heidelberg will unveil a new range of Speedmaster models at drupa 2020, with the range featuring new Push to Stop functionalities and a cloud connection.

The company said the models will be the “most intelligent and most automated Speedmasters of all time” with small, medium and large format units equipped with the new standard functionality.

Heidelberg head of sheet-fed product management Rainer Wolf said this will enable all customer groups to enjoy the increasing range of cloud-based software solutions and benefit from future developments.

“These integrated measures will enable our customers to take the next step at drupa 2020 towards much higher productivity and process reliability. Our forecast at drupa 2016 that the industry would double its productivity by 2026 is on its way to becoming a reality, and Push to Stop is the key to this,” Wolf said.

“We will present all kinds of technical innovations at drupa 2020 to solve our customers’ concrete problems and close gaps in the automation chain. Interesting innovations in the area of intelligent assistance systems and artificial intelligence will be an impressive display of what is already possible today and where development will lead in the coming years.

“We are consistently thinking beyond the printing press here also, for example in the area of printing plate logistics.”

The new Speedmaster drupa 2020 generation is expected to go into production as early as April.

Heidelberg will also launch its new plate-to-unit fully automatic printing plate logistics solution at the tradeshow.

Here the printing plates are provided fully automatically in the correct plate changing shaft and the used plates are removed.

Wolf mentioned that this is the only way to achieve consistently high productivity with short runs in addition to reducing the operator’s workload, and increasing process reliability.

“This increases the reliability of plate changes and reduces the risk of scratches on the plate causing paper waste. There’s no point in just increasing the speed of the printing press,” Wolf said.

“That would be like being stuck in a traffic jam and expecting a faster car to solve the problem. Optimised, coordinated overall processes are a much more effective way of increasing productivity in the long term – they solve the traffic jam and deliver continuous schedulable productivity at the highest level. This is exactly where our focus lies.”

At drupa 2020, Heidelberg will also address the increasing job complexity in the press room with the simultaneous increase in requirements for operator qualification and improved productivity.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter