These are designed to meet diverse customer needs for general commercial, direct mail, transpromo, newspaper, book and variable data applications.

Screen will launch the complete EQUIOS universal workflow and demonstrate the latest enhancements to its successful Truepress Jet520 digital web press at drupa.

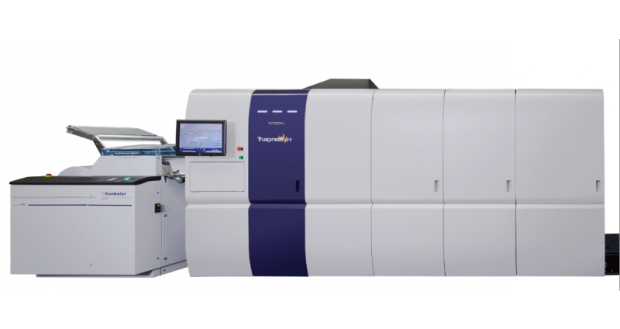

Meanwhile, the digital sheetfed Truepress JetSX, previewed at Ipex 2010, will be launched commercially along with several enhancements.

Screen will also reveal new products at drupa for wide-format inkjet and the label industry that further extends its POD offerings.

“Despite challenging global economic times and pressures on the print industry, Screen remains a strong and profitable company that is undergoing an exciting transition,” says Katsuhiko Aoki, president of Dainippon Screen’s Media & Precision Technology Company.

“Our strategy of evolving into a digital print company to meet the changing needs of the graphics market began in 2006 and at drupa this year we present a range of powerful digital print on demand solutions. Today we are proud to be the world’s leading manufacturer of both high-volume web-fed inkjet printers and CTP devices.”

At drupa, Screen will launch its EQUIOS Universal workflow, designed for conventional and personalised printing environments. This single workflow with a single interface drives streamlined production from web to print to the delivery of the finished item automatically.

EQUIOS provides integrated job management with consistent colour management across different output devices. Communication with a variety of third-party finishing systems is automated via EQUIOS JDF.

The EQUIOS Autoflow function, to be shown for the first time at drupa, will allow users to define print workflows according to the product type selected. This can be integrated into any web2print interface so that web ordering automatically generates a print queue and associated finishing instructions.

A world first for Screen at drupa 2012 will be the introduction of a cloud-based variable data application that simplifies the production of variable jobs and gives printers an investment-free entry into the fastest growing area of printing. Designers and data owners can collaborate on projects via a standard web browser before the finished file is sent to the print provider (EQUIOS user). This service will be demonstrated on the stand at drupa and launched within the next twelve months claims Screen.

Previewed at Ipex 2010, the B2 sheetfed Truepress JetSX inkjet press will be launched commercially at drupa. This advanced full-colour press with full variable data and duplex printing capability prints 1620 B2 sheets/hour, equivalent to 108 A4 pages/minute. Enhancements to its specifications include the ability to handle offset and inkjet papers and boards up to 0.6 millimetre, and the ability to print fully variable data to any level of output from the Screen EQUIOS front end.

This press handles a wide range of substrates with ease and is aimed at niche applications that require the B2 format that cannot be printed on the current range of toner devices. In addition, anything that can also be printed on a B3 press can be printed on the Truepress JetSX. Its ability to print onto boards up to 0.6 microns (simplex mode), including textured substrates, makes it ideal for personalised photo, photobook, gift, packaging and prototyping applications.

The Truepress JetSX, combined with the EQUIOS front end and third party finishing equipment, can be integrated to provide a highly automated, web to delivery solution. Files received online can be automatically preflighted, colour managed, imposed and placed in the print queue. Once the job is printed, EQUIOS passes the necessary information through to an MIS system for automatic billing if required.

The Truepress JetSX will go into production at a beta site in Europe after drupa.

The launch of the Truepress JetSX follows on from Screen’s highly successful Truepress Jet520. Screen claims the Truepress Jet520 range, launched in 2006, is today the most successful high-volume digital web-fed inkjet press in the world, with close to a 50 per cent market share. Screen has shipped over 400 machines, including those manufactured for Ricoh, and 2011/12 is shaping up to be its best year to date for sales.

At drupa, Screen launches JetInspection JI-500, a web inspection option for the Truepress Jet520 that captures every pixel of every page as it is printed and compares it against the RIP data to ensure full data integrity. JetInspection JI-500 is integrated into EQUIOS so that, if it monitors an error, the finishing line is notified to reject the page and a new one is activated – all automatically. This option is particularly important for data critical transpromo and billing applications.

In the prepress arena, Screen has been manufacturing PlateRite CTP devices for over 10 years and lays claim to being the world’s leading developer with the largest market share (41.4 per cent) and over 17,500 units sold, most still in use. The company offers 26 different highly-automated models spanning 4-, 6-, 8-, 16-, 24-, 36-, 40- and 48-page formats.

Screen is expanding its range of CTP devices for the flexo packaging industry. It offers the Screen PlateRite FX range of thermal platesetters to image all market-leading solvent and water-wash photopolymer plates for flexo and letterpress applications to the highest 4,800 dpi quality levels.

Screen remains committed to CTP and, to further strengthen its position, has recently completed a factory in China to manufacture all its 4- and 8-page PlateRite units.

Says Katsuhiko Aoki: “We are encouraging print firms to take a closer look, not only at the impressive capabilities of Screen’s expert workflow and digital presses, but also at the considerable benefits these can bring to their business in the range of quality, value-added products they can deliver supported by low running and maintenance costs and high environmental credentials.”

See Screen at drupa, Hall 9/A40.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter